LTC1278

O U

S

W

U

PPLICATI

I FOR ATIO

A

R1

50Ω

R1

10k

ANALOG

INPUT

V1

+

–

+

–

R2

10k

A1

A

IN

A

IN

R4

100k

R4

100Ω

R2

10k

R5

4.3k

LTC1278

LTC1278

FULL-SCALE

ADJUST

R3

FULL-SCALE

ADJUST

5V

10k

R3

AGND

R7

R8

20k

100k

LTC1278 F9a

LTC1278 F9c

100k

ADDITIONAL PINS OMITTED FOR CLARITY

OFFSET

ADJUST

±20LSB TRIM RANGE

R6

200Ω

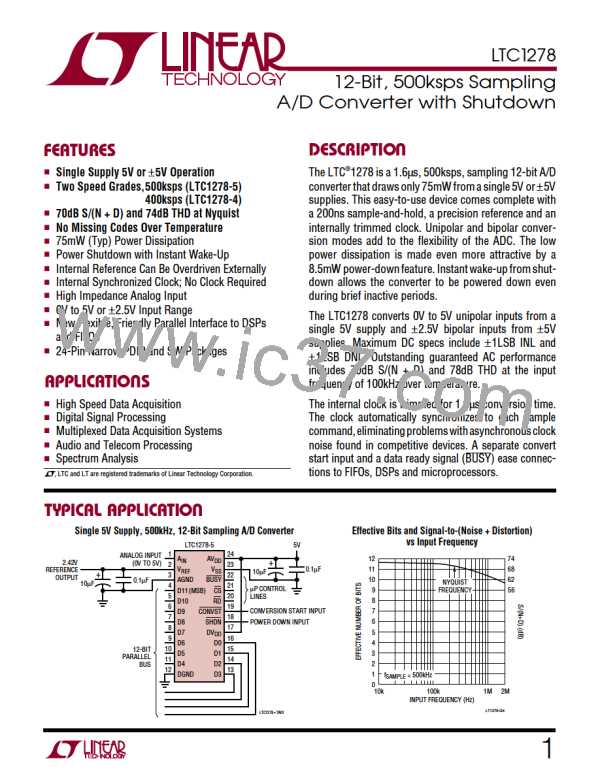

Figure 9a. Full-Scale Adjust Circuit

–5V

R1

10k

Figure 9c. LTC1278 Bipolar Offset and Full-Scale Adjust Circuit

ANALOG

INPUT

+

0V TO 5V

R2

driving the analog input of the LTC1278 while the input

voltage is 1/2LSB below ground. This is done by applying

an input voltage of –0.61mV (–0.5LSB) to the input in

Figure 9c and adjusting the R8 until the ADC output code

flickers between 0000 0000 0000 and 1111 1111 1111.

For full-scale adjustment, an input voltage of 2.49817V

(FS – 1.5LSBs) is applied to the input and R5 is adjusted

until the output code flickers between 0111 1111 1110

and 0111 1111 1111.

A

IN

10k

10k

R4

5V

–

100k

R9

20Ω

R5

4.3k

FULL-SCALE

ADJUST

LTC1278

5V

R3

100k

R7

R8

10k

LTC1278 F9b

100k

OFFSET

ADJUST

R6

400Ω

BOARD LAYOUT AND BYPASSING

Figure 9b. LTC1278 Unipolar Offset and Full-Scale Adjust Circuit

Wire wrap boards are not recommended for high resolu-

tion or high speed A/D converters. To obtain the best

performance from the LTC1278, a printed circuit board is

required. Layout for the printed circuit board should

ensure that digital and analog signal lines are separated as

much as possible. In particular, care should be taken not

to run any digital track alongside an analog signal track or

underneath the ADC. The analog input should be screened

by AGND.

Unipolar Offset and Full-scale Error Adjustments

Inapplicationswhereabsoluteaccuracyisimportant,then

offset and full-scale errors can be adjusted to zero. Offset

error must be adjusted before full-scale error. Figure 9a

shows the extra components required for full-scale error

adjustment. If both offset and full-scale adjustments are

needed, thecircuitinFigure9bcanbeused. Forzerooffset

error apply 0.61mV (i.e., 1/2LSB) at the input and adjust

the offset trim until the LTC1278 output code flickers

between 0000 0000 0000 and 0000 0000 0001. For zero

full-scale error apply an analog input of 4.99817V (i.e., FS

– 1 1/2LSB or last code transition) at the input and adjust

R5 until the LTC1278 output code flickers between 1111

1111 1110 and 1111 1111 1111.

High quality tantalum and ceramic bypass capacitors

should be used at the AVDD and VREF pins as shown in

Figure 10. For the bipolar mode, a 0.1µF ceramic provides

adequate bypassing for the VSS pin. The capacitors must

be located as close to the pins as possible. The traces

connecting the pins and the bypass capacitors must be

kept short and should be made as wide as possible.

Bipolar Offset and Full-scale Error Adjustments

Input signal leads to AIN and signal return leads from

AGND (Pin 3) should be kept as short as possible to

minimize input noise coupling. In applications where this

is not possible, a shielded cable between source and ADC

is recommended.

Bipolaroffsetandfull-scaleerrorsareadjustedinasimilar

fashion to the unipolar case. Again, bipolar offset must be

adjusted before full-scale error. Bipolar offset error ad-

justment is achieved by trimming the offset of the op amp

12

Linear [ Linear ]

Linear [ Linear ]