LT8705

APPLICATIONS INFORMATION

If the inductor value is already known then ∆I

constant(frequency=350kHz,inductance=10μH,R

=

L(MIN,BUCK)

SENSE

can be calculated as follows:

10mΩ).Thisgraphisnormalizedandaccountsforchanges

inmaximumcurrentduetotheslopecompensationramps

and the effects of changing ripple current. The curve is

theoretical, but can be used as a guide to predict relative

changes in maximum output and inductor current over a

DC

(MIN,M2,BUCK)

•VOUT(MIN)

100%

∆IL(MIN,BUCK

=

A

)

f•L

range of V /V

voltages.

IN OUT

where:

DC

is the minimum duty cycle percentage

(MIN,M2,BUCK)

in the buck region as calculated previously.

Reverse Current Limit

When the forced continuous mode is selected (MODE

pin low), inductor current is allowed to reverse directions

f is the switching frequency

and flow from the V

side to the V side. This can lead

OUT

IN

L is the inductance of the main inductor

After the inductor ripple current is known, the maximum

to current sinking from the output and being forced into

the input. The reverse current is at a maximum magni-

allowed R

follows:

in the buck region can be calculated as

SENSE

tude when V is lowest. The graph of Minimum Inductor

C

Current Sense Voltage in FCM in the Typical Performance

Characteristicssectioncanhelptodeterminethemaximum

reverse current capability.

2•86mV

RSENSE(MAX,BUCK)

=

2•I

– ∆I

L(MIN,BUCK)

(

)

OUT(MAX,BUCK)

Inductor Selection

Final R

Value: The final R

value should be

SENSE(MAX,BUCK)

SENSE

lowerthanbothR

SENSE

For high efficiency, choose an inductor with low core

loss, such as ferrite. Also, the inductor should have low

andR

.

SENSE(MAX,BOOST)

A margin of 30% or more is recommended.

2

DC resistance to reduce the I R losses, and must be able

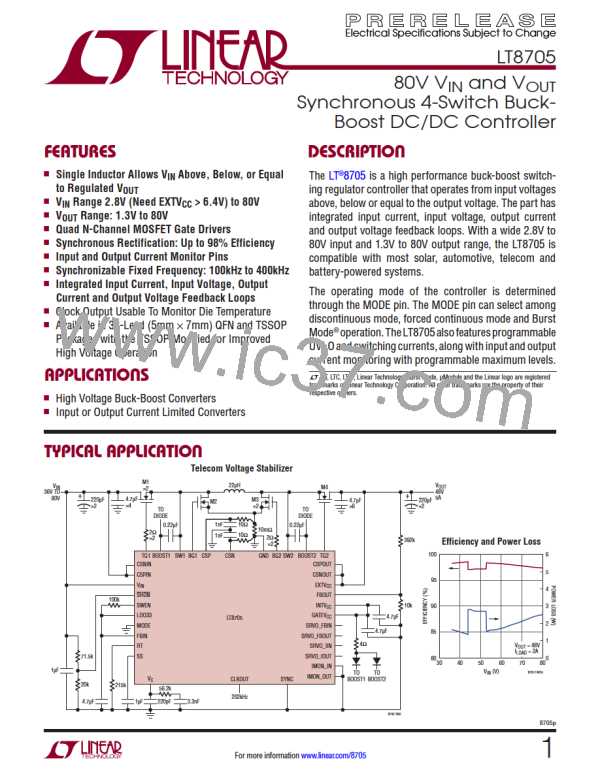

Figure 8 shows approximately how the maximum output

current and maximum inductor current would vary with

to handle the peak inductor current without saturating. To

minimize radiated noise, use a toroid, pot core or shielded

bobbin inductor.

V /V

IN OUT

while all other operating parameters remain

1.0

The operating frequency and inductor selection are inter-

related in that higher operating frequencies allow the use

of smaller inductor and capacitor values. The following

sectionsdiscussseveralcriteriatoconsiderwhenchoosing

an inductor value. For optimal performance, choose an

inductor that meets all of the following criteria.

0.8

MAXIMUM

INDUCTOR

CURRENT

0.6

MAXIMUM

OUTPUT

CURRENT

0.4

Inductor Selection: Adequate Load Current in the

Boost Region

0.2

0

Small value inductors result in increased ripple currents

andthus,duetothelimitedpeakinductorcurrent,decrease

the maximum average current that can be provided to the

10

0.1

1

V

/V

(V/V)

IN OUT

8705 F08

load (I ) while operating in the boost region.

OUT

Figure 8. Currents vs VIN/VOUT Ratio

8705p

23

For more information www.linear.com/8705

Linear [ Linear ]

Linear [ Linear ]