LT3592

APPLICATIONS INFORMATION

V

OUT

I

LED

V

SW

100μs/DIV

C = 4.7μF

V

OUT

I

LED

V

SW

3592 F04

100μs/DIV

C = 10μF

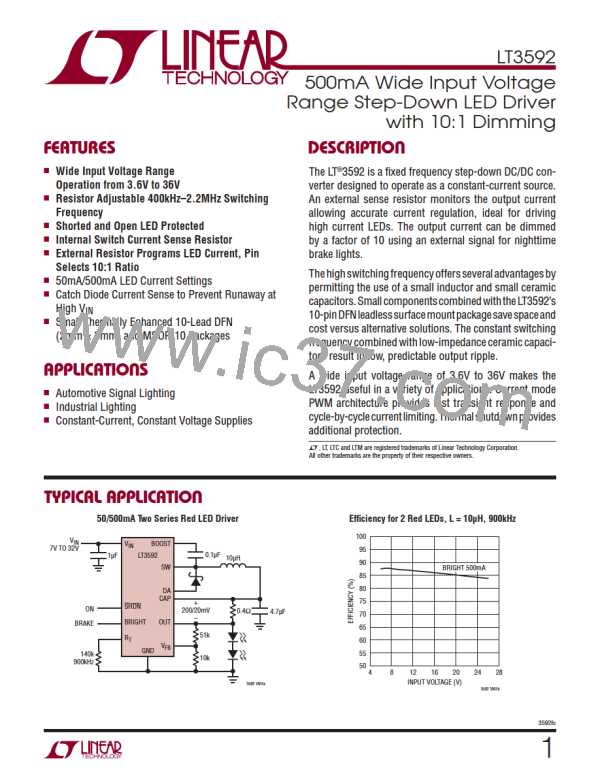

Figure 4. Transient Load Response of the LT3592 with Different Output Capacitors

D2

D2

OPTIONAL

C3

BOOST

BOOST

C3

CAP

CAP

LT3592 SW

LT3592 SW

V

V

IN

BATT

BATT

IN

GND

DA

GND

DA

3592 F05a

3592 F05b

(5a)

(5b)

Figure 5. Two Circuits for Generating the Boost Voltage

BOOST Pin Considerations

parallel with the internal Schottky diode, anode to CAP

and cathode to BOOST. For outputs between 3.3V and

12V, the 0.1μF cap and the internal boost diode will be

effective. For 3V to 3.3V outputs, use a 0.22μF capacitor.

For output between 2.5V and 3V, use a 0.47μF capacitor

and an external Schottky diode connected as shown in

Figure 5a. For lower output voltages, the external boost

diode’s anode can be tied to the input voltage. This con-

nectionisnotasefficientastheothersbecausetheBOOST

pin current comes from a higher voltage. The user must

alsobesurethatthemaximumvoltageratingoftheBOOST

pin is not exceeded.

The capacitor C3 and an internal Schottky diode from

the CAP to the BOOST pin are used to generate a boost

voltage that is higher than the input voltage. An external

fast switching Schottky diode (such as the BAS40) can

be used in parallel with the internal diode to make this

boost circuit even more effective. In most cases, a 0.1μF

capacitor works well for the boost circuit. The BOOST pin

must be at least 2.5V above the SW pin for best efficiency.

For output voltages above 12V, use a 0.1μF cap and an

external boost diode (such as a BAS40) connected in

3592fc

14

Linear Systems [ Linear Systems ]

Linear Systems [ Linear Systems ]