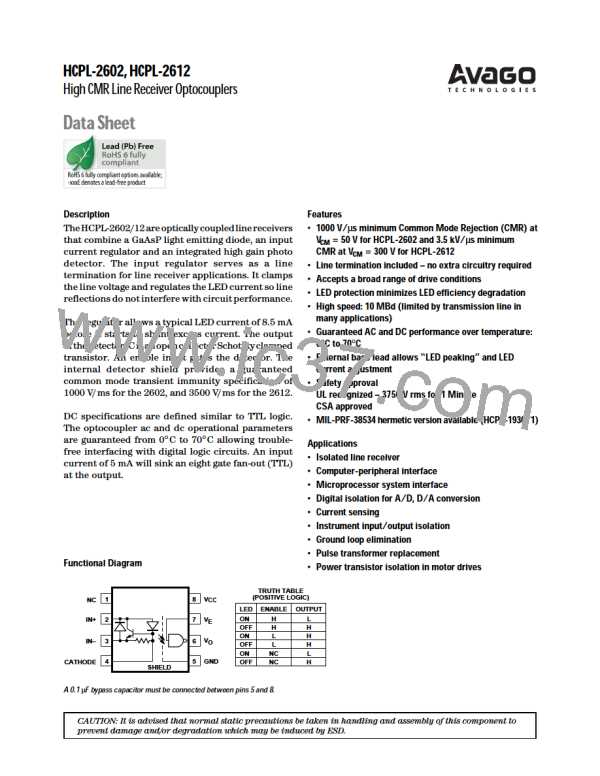

Solder Reflow Thermal Profile

Regulatory Information

The HCPL-2602/2612 have been

approved by the following

organizations:

300

PREHEATING RATE 3°C + 1°C/–0.5°C/SEC.

REFLOW HEATING RATE 2.5°C ± 0.5°C/SEC.

PEAK

TEMP.

245°C

PEAK

TEMP.

240°C

PEAK

TEMP.

230°C

UL

200

100

0

2.5°C ± 0.5°C/SEC.

Recognized under UL 1577,

Component Recognition Program,

File E55361.

SOLDERING

TIME

200°C

30

160°C

150°C

140°C

SEC.

30

SEC.

3°C + 1°C/–0.5°C

CSA

PREHEATING TIME

150°C, 90 + 30 SEC.

50 SEC.

Approved under CSA Component

Acceptance Notice #5, File CA

88324.

TIGHT

TYPICAL

LOOSE

ROOM

TEMPERATURE

0

50

100

150

200

250

TIME (SECONDS)

Note: Non-halide flux should be used.

Recommended Pb-Free IR Profile

TIME WITHIN 5 °C of ACTUAL

PEAKTEMPERATURE

t

p

20-40 SEC.

260 +0/-5 °C

T

T

p

217 °C

L

RAMP-UP

3 °C/SEC. MAX.

RAMP-DOWN

6 °C/SEC. MAX.

150 - 200 °C

T

smax

T

smin

t

s

t

L

60 to 150 SEC.

PREHEAT

60 to 180 SEC.

25

t 25 °C to PEAK

TIME

NOTES:

THE TIME FROM 25 °C to PEAK TEMPERATURE = 8 MINUTES MAX.

= 200 °C, T = 150 °C

T

smax

smin

Note: Non-halide flux should be used.

Insulation and Safety Related Specifications

Parameter

Symbol

Value Units Conditions

Min. External Air Gap

(External Clearance)

L(I01)

7.1

mm

mm

mm

Measured from input terminals to output terminals,

shortest distance through air.

Min. External Tracking

Path (External Creepage)

L(I02)

CTI

7.4

Measured from input terminals to output terminals,

shortest distance path along body.

Min. Internal Plastic

Gap (Internal Clearance)

0.08

Through insulation distance, conductor to conductor,

usually the direct distance between the photoemitter

and photodetector inside the optocoupler cavity.

Tracking Resistance

(Comparative Tracking

Index)

200

IIIa

V

DIN IEC 112/ VDE 0303 Part 1

Isolation Group

Material Group (DIN VDE 0110, 1/ 89, Table 1)

Option 300 - surface mount classification is Class A in accordance with CECC 00802.

5

AVAGO [ AVAGO TECHNOLOGIES LIMITED ]

AVAGO [ AVAGO TECHNOLOGIES LIMITED ]