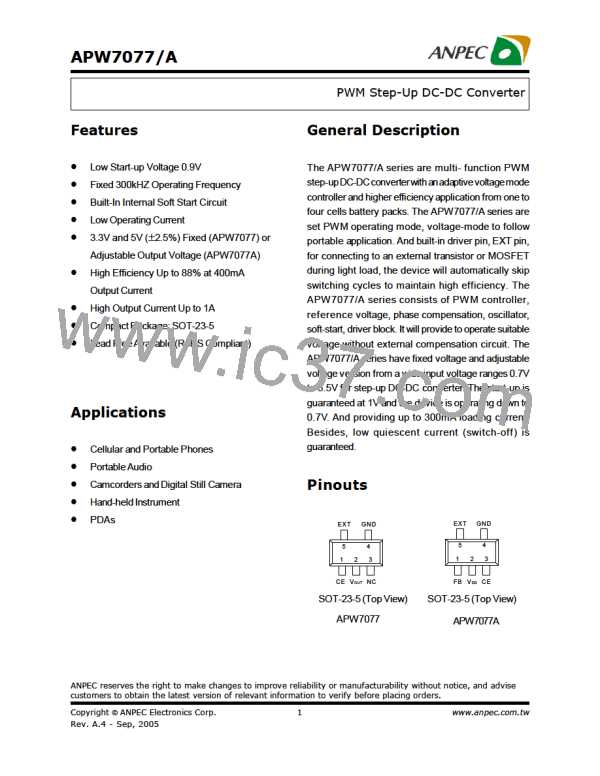

APW7077/A

Function Description (Cont.)

Inductor Selection (Cont.)

If the regulator will be loaded uniformly, with very little

load changes, and at lower current outputs, the input

capacitor size canoften be reduced. The size can also

be reduced if the input of the regulator is very close to

the source output. The size will generally need to be

larger for applicationswherethe regulator issupplying

nearly the maximum ratedoutput or if large load steps

are expected. A minimum value of 10µF should be

used for the less stressful conditions while a 22µF to

47µF capacitor may be required for higher power and

dynamic loads. Small ESR Tantalum or ceramic ca-

pacitor should be suitable and the total input ripple

voltage canbe calculated

when DIL is less than the average inductor current.

Care must be taken to make sure that the switch will

not reach its current limit during normal operation.

The inductor must also be sized accordingly. It should

have a saturation current rating higher than the peak

inductor current expected. The output voltage ripple is

also affected by the total ripple current.

Output Capacitor

The output capacitor is used for sustaining the output

voltage when the external MOSFET or bipolar

transistor is switched on and smoothing the ripple

voltage.

DVIN = DIL ´ ESR

Design Example

The output capacitance needed is calculated in

equations.

It is supposed that a step–up DC–DC controller with

3.3 V output delivering a maximum 1000 mA output

current with 100 mV output ripple voltage powering

from a 2.4 V input is to be designed.

IO(max) ´ D

COUT(min) =

fsw ´ DVOUT

The ESR is also important because it determines the

peak to peak output voltage ripple according to the

approximateequation:

Design parameters:

VIN = 2.4 V

?V

OUT

VOUT = 3.3 V

ESR =

?I

O

IO = 1.0 A

With 1% output voltage ripple, low ESR capacitor

should be used to reduce output ripple voltage. In

DVOUT = 100 mV

fsw= 300 kHZ

general, a 100uF to 220uF low ESR (0.10W to 0.30W)

Tantalum capacitor should be appropriate. The choice

of output capacitors is also somewhat arbitrary and

dependson the designrequirementsfor output voltage

ripple.Aminimum value of 10µF isrecommended and

may be increased to a larger value.

Ratio = 0.2 (typical for small output ripple voltage)

Assume the diode forward voltage and the transistor

saturation voltageare both 0.3V. Determine the maxi-

mum steady state duty cycle at VIN = 2.4 V:

D=0.273

Calculate the maximum inductance value which can

generate the desired current output and the preferred

deltainductor current to averageinductor current ratio:

Input Capacitor

The input capacitor can stabilize the input voltage and

minimize peak current ripplefrom the source. Thesize

usedis dependant on the applicationand board layout.

L=10uH

Copyright ã ANPEC Electronics Corp.

14

www.anpec.com.tw

Rev. A.4 - Sep, 2005

ANPEC [ ANPEC ELECTRONICS COROPRATION ]

ANPEC [ ANPEC ELECTRONICS COROPRATION ]