AN-32

Step-by-Step Design Procedure

• Power supply efficiency, η: 0.8 if no better reference data

available. (Refer to AN-29)

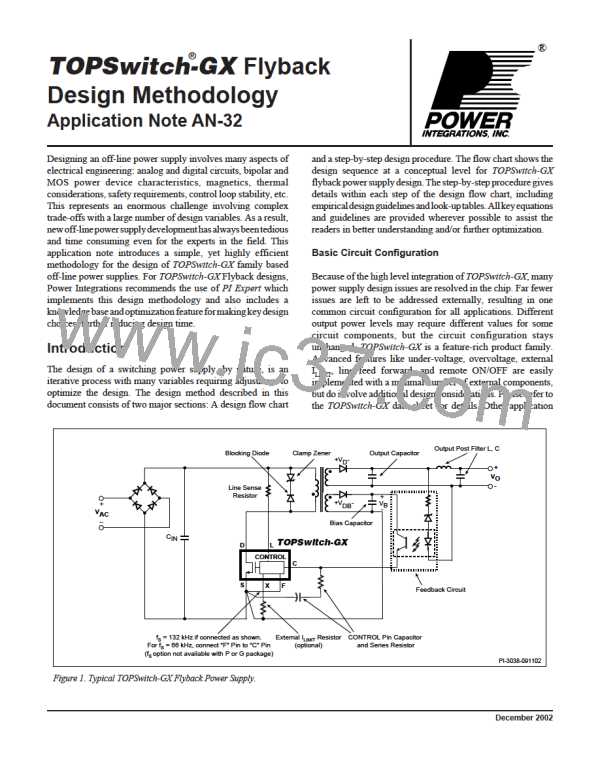

ThisdesignprocedureusesthePIExpertdesignsoftware(available

from Power Integrations), which contains all the important

equations required for a TOPSwitch-GX flyback power supply

design,andautomatesmostcalculations.Designersare,therefore,

relievedfromthetediouscalculationsinvolvedinthecomplicated

and highly iterative design process. Look-up tables and empirical

designguidelinesareprovidedinthisprocedurewhereappropriate

to facilitate the design task.

• Loss allocation factor, Z: If Z = 1, all losses are on the

secondary side. If Z = 0, all losses are on the primary side.

Set Z = 0.5 if no better reference data is available.

Step 2. Choose feedback circuit and bias voltage VB based

on output requirements

Feedback

Circuit

VB Circuit Load* Line

(V) Tolerance Reg. Reg.

Total

Reg.

Step 1. Determine system requirements: VACMAX, VACMIN

,

fL, VO, PO, η, Z

Pri./Basic 5.8 ±10%

Pri./Enhan. 27.8 ±5%

±5% ±1.5% ±16.5%

±2.5% ±1.5% ±9%

±1% ±0.5% ±6.5%

±0.2% ±0.2% ±1.4%

• Minimum AC input voltage, VACMIN: in volts.

• Maximum AC input voltage, VACMAX: in volts.

• Recommended AC input ranges:

Opto/Zener 12

Opto/TL431 12

±5%

±1%

*Over 10% to 100% Load Range.

Table 2.

Input (VAC)

Universal

VACMIN (VAC) VACMAX (VAC)

85

265

265

• Use primary feedback for lowest cost (for low power

applications only).

230 or 115 with doubler

195

• Use Opto/Zener for low cost, good output accuracy.

• Use Opto/TL431 for best output accuracy.

• Set bias voltage VB according to Table 2.

• Choose optocoupler from Table 3.

Table 1.

• Line frequency, fL: 50 Hz or 60 Hz.

• Output voltage, VO: in Volts.

• Output power: PO: in Watts.

+

+

VO

-

VAC

CIN

Feedback Circuit

TOPSwitch-GX

15 Ω

D

S

L

CONTROL

C

X

F

CIRCUIT PERFORMANCE

Circuit Tolerance ±10%

Load Regulation ±5%

Line Regulation ±1.5%

PI-3331-112202

Figure 3. Primary/Basic Feedback Circuit.

B

12/02

5

ETC [ ETC ]

ETC [ ETC ]