TMC5130A DATASHEET (Rev. 1.14 / 2017-MAY-15)

5

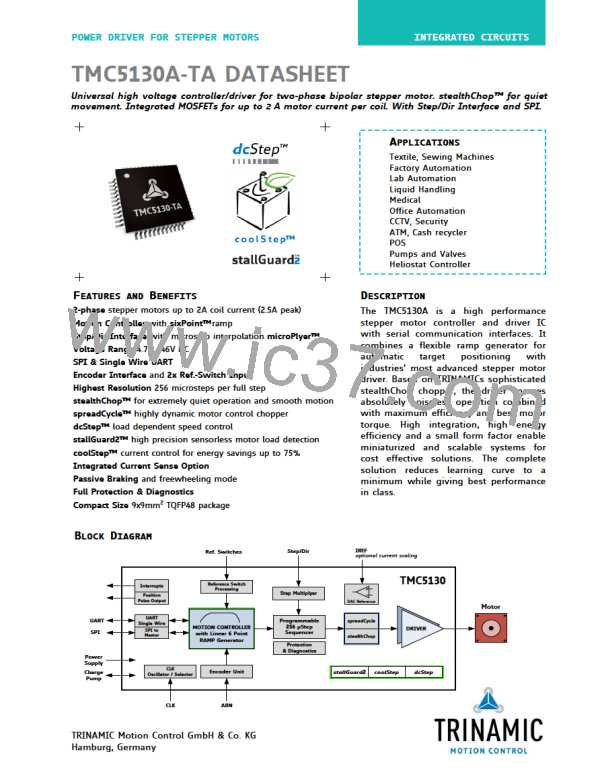

1 Principles of Operation

The TMC5130A motion controller and driver chip is an intelligent power component interfacing

between CPU and stepper motor. All stepper motor logic is completely within the TMC5130A. No

software is required to control the motor – just provide target positions. The TMC5130A offers a

number of unique enhancements which are enabled by the system-on-chip integration of driver and

controller. The sixPoint ramp generator of the TMC5130A uses stealthChop, dcStep, coolStep, and

stallGuard2 automatically to optimize every motor movement.

THE TMC5130A OFFERS THREE BASIC MODES OF OPERATION:

MODE 1: Full Featured Motion Controller & Driver

All stepper motor logic is completely within the TMC5130A. No software is required to control the

motor – just provide target positions. Enable this mode by tying low pin SD_MODE.

MODE 2: Step & Direction Driver

An external high-performance S-ramp motion controller like the TMC4361 or a central CPU generates

step & direction signals synchronized to other components like additional motors within the system.

The TMC5130A takes care of intelligent current and mode control and delivers feedback on the state of

the motor. The microPlyer automatically smoothens motion. Leave open SD_MODE and SPI_MODE.

MODE 3: Simple Step & Direction Driver

The TMC5130A positions the motor based on step & direction signals. The microPlyer automatically

smoothens motion. No CPU interaction is required; configuration is done by hardware pins. Basic

standby current control can be done by the TMC5130A. Optional feedback signals allow error detection

and synchronization. Enable this mode by tying low pin SPI_MODE.

reference / stop switches

optional current scaling

5VOUT

RREF

Optional for internal

current sensing.

RREF=9K1 allows for

maximum coil current.

+VM

TMC 5130A

Stepper motor driver /

controller

100n

VS

reference switch

processing

+VM

VCP

CPI

OA1

Half Bridge 1

Half Bridge 2

DAC Reference

IREF

100n

22n

charge pump

ISENSE

ISENSE

CPO

Step &

Direction pulse

generation

linear 6 point RAMP

generator

VSA

OA2

BRA

5V Voltage

regulator

5VOUT

&

p

e

t

100n

l

o

r

S

t

n

l

o

o

4.7µ

o

2R2

c

c

p

r

e

o

n

h

o

i

VCC

C

t

RS

h

o

t

2R2 and 470n are optional

filtering components for

best chopper precision

l

M

PU=166K pullup resistor to VCC

a

e

t

s

470n

GNDP

v

PD=166k pull down resistor to GND

i

r

d

r

PU

CSN

SCK

o

t

IREF

o

m

current

PU

DRV_ENN

DAC

DAC

comparator

spreadCycle &

stealthChop

Chopper

RS=0R15 allows for

maximum coil current;

Use low inductance

SMD resistor type.

Tie BRA and BRB to

GND for internal

SPI interface

SPI™

PU

SDI/NAI

programmable

sine table

4*256 entry

N

Control register

set

PU

SDO/NAO

x

S

e

c

a

f

r

Stepper driver

Protection

& diagnostics

e

t

n

2 phase

stepper

motor

current sensing

I Single wire

PD

interface selection

(-TA package only)

SW_SEL

current

interface

(-TA pckg only)

comparator

GNDP

IREF

PDD=100k pulldown

PMD=50k to VCC/2

single wire

UART

Opt. interrupt out

coolStep™

RS

PDD

SWP_DIAG1

SWN_DIAG0

BRB

PMD

Opt. poscomp out

stallGuard2™

Diff. Tranceiver

OB2

Half Bridge 2

Half Bridge 1

INT & position

pulse output

ISENSE

dcStep™

opt. ext. clock

10-16MHz

CLK_IN

VCC_IO

OB1

VS

CLK oscillator/

selector

Encoder

unit

B

+VIO

A

N

ISENSE

3.3V or 5V

I/O voltage

100n

+VM

100n

Optional incremental

encoder inputs

leave open

opt. driver enable

Figure 1.1 TMC5130A basic application block diagram with motion controller

www.trinamic.com

TRINAMIC [ TRINAMIC MOTION CONTROL GMBH & CO. KG. ]

TRINAMIC [ TRINAMIC MOTION CONTROL GMBH & CO. KG. ]