RT9214

Under Voltage Protection

placement layout and printed circuit design can minimize

the voltage spikes induced in the converter. Consider, as

an example, the turn-off transition of the upper MOSFET

prior to turn-off, the upper MOSFET was carrying the full

load current. During turn-off, current stops flowing in the

upper MOSFET and is picked up by the low side MOSFET

or schottky diode. Any inductance in the switched current

path generates a large voltage spike during the switching

interval. Careful component selections, layout of the

critical components, and use shorter and wider PCB traces

help in minimizing the magnitude of voltage spikes.

The voltage at FB pin is monitored and protected against

UV (under voltage). The UV threshold is the FB or FBL

under 80%. UV detection has 15μs triggered delay. When

OC is trigged, a hiccup restart sequence will be initialized,

as shown in Figure 7 Only 4 times of trigger are allowed

to latch off. Hiccup is disabled during soft-start interval,

but UV_FB has some difference from OC, it will always

trigger VIN power sensing after 4 times hiccup, as shown

in Figure 8.

COUNT = 1

COUNT = 2

COUNT = 3

COUNT = 4

There are two sets of critical components in a DC-DC

converter using the RT9214. The switching power

components are most critical because they switch large

amounts of energy, and as such, they tend to generate

equally large amounts of noise. The critical small signal

components are those connected to sensitive nodes or

those supplying critical bypass current.

4V

2V

0V

OVERLOAD

APPLIED

0A

T0

T1

T2

T3

T4

The power components and the PWM controller should

be placed firstly. Place the input capacitors, especially

the high-frequency ceramic decoupling capacitors, close

to the power switches. Place the output inductor and

output capacitors between the MOSFETs and the load.

Also locate the PWM controller near by MOSFETs.

TIME

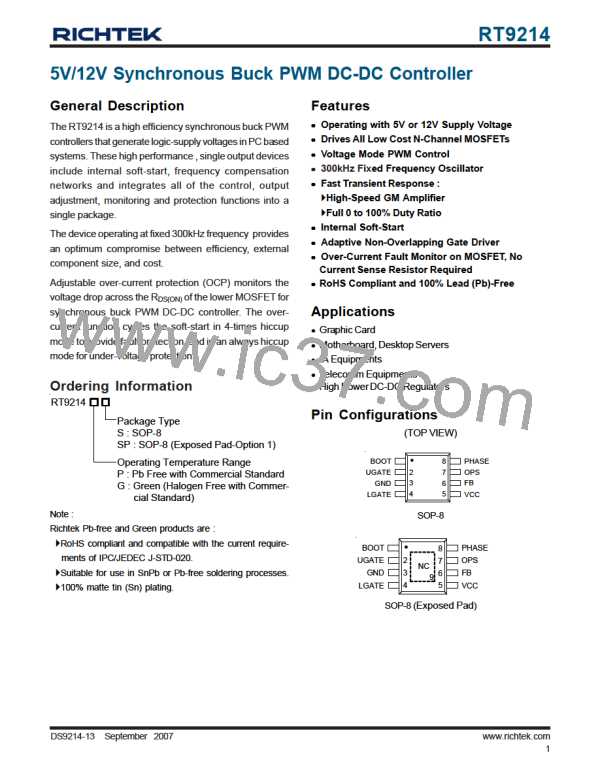

Figure 7. UV and OC trigger hiccup mode

Power Off

A multi-layer printed circuit board is recommended.

UGATE

FB

(20V/Div)

Figure 9 shows the connections of the critical components

in the converter. Note that the capacitors CIN and COUT

each of them represents numerous physical capacitors.

Use a dedicated grounding plane and use vias to ground

all critical components to this layer. Apply another solid

layer as a power plane and cut this plane into smaller

islands of common voltage levels. The power plane should

support the input power and output power nodes. Use

copper filled polygons on the top and bottom circuit layers

for the PHASE node, but it is not necessary to oversize

this particular island. Since the PHASE node is subjected

to very high dV/dt voltages, the stray capacitance formed

between these island and the surrounding circuitry will

tend to couple switching noise. Use the remaining printed

circuit layers for small signal routing. The PCB traces

between the PWM controller and the gate of MOSFET

and also the traces connecting source of MOSFETs should

be sized to carry 2A peak currents.

UV

VIN Power

Sensing

(500mV/Div)

VOUT

VIN

(2V/Div)

(2V/Div)

IOUT = 2A

Time (10ms/Div)

Figure 8, UV_FB trigger VIN power sensing

PWM Layout Considerations

MOSFETs switch very fast and efficiently. The speed with

which the current transitions from one device to another

causes voltage spikes across the interconnecting

impedances and parasitic circuit elements. The voltage

spikes can degrade efficiency and radiate noise, that results

in over-voltage stress on devices. Careful component

www.richtek.com

13

DS9214-13 September 2007

RICHTEK [ RICHTEK TECHNOLOGY CORPORATION ]

RICHTEK [ RICHTEK TECHNOLOGY CORPORATION ]