To be transferred to Honda Tsushin kogyo Co.,Ltd. from October 1, 2009

AXA2R

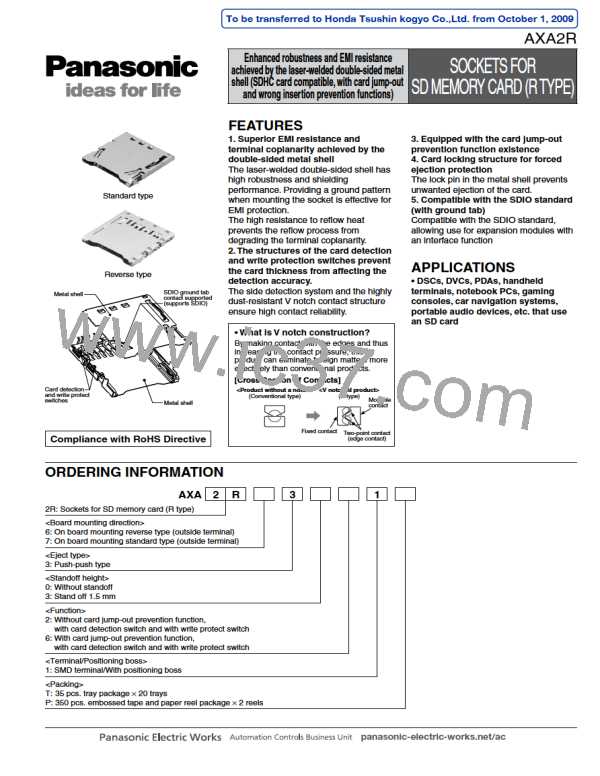

EMBOSSED TAPE AND REEL (Unit: mm)

• Tape dimensions

• Reel dimensions (Conforming to JIS C0806-1995)

Socket for SD memory card

Emboss

carrier tape

Taping reel

(44.4)+2

Top cover tape

0

Top cover

tape

Tape

Emboss carrier tape

Cavity

Label

(1.75)

20.20

40.40

44.00

NOTES

1.Regarding the design of PC board

patterns

(6) Measure the temperature at the

connector surface.

2) Be cautious when handling because

excessive force applied to the terminals

will cause deformation and loss of

terminal coplanarity.

3) Repeated bending of the terminals

may break them.

Conduct the recommended foot pattern

design, in order to preserve the

mechanical strength of terminal solder

areas.

(7) If the reverse side of the board

undergoes reflow soldering after the

socket is reflow-soldered, fix the socket

with tape or adhesive; otherwise, the

socket may drop. The socket can

withstand two iterations of reflow

soldering.

2. Regarding the socket mounting

1) When reflow soldering when the slider

is locked, heat will cause the slider to

deform and not work. Therefore, please

confirm that the slider lock is released

before mounting if you have inserted and

removed a card before soldering.

2) Be aware that during mounting,

external forces may be applied to the

connector contact surfaces and terminals

and cause deformations.

7. Card fitting

1) These products are made for the

design of compact and lightweight

devices and therefore the molded part is

very thin. For this reason, design the

device to prevent undue wrenching forces

from being applied to the product during

use.

2) The sockets are constructed to prevent

reverse card insertion. Caution is

required because repeated, mistaken

reverse insertion may damage the socket

and card.

3) When not soldered, be careful not to

insert and remove the socket’s card.

Doing so will cause a decrease in

anchoring ability of the molded part and

loss of coplanarity.

4) Forcibly removing a fitted card may

degrade the card removal prevention

lock. To remove a card, be sure to push

the card in the insertion direction to

release the slider lock before pulling out

the card.

2) Hand soldering

• Set the soldering tip to 300°C, and

solder for no more than 5 seconds.

• Be aware that for the 0 mm standoff

type, solder creeping at the retention

solder tab sections may occur if soldering

is conducted for long periods or if too

much solder is used.

3. Soldering

1) Reflow soldering

4. Cleaning after soldering

Inside the socket there is a slider section

and card detection contact/write

protection mechanism. If anything such

as flux remains inside after washing,

insertion and removal will be hampered

and contact will be faulty. Therefore, do

not use methods that involve submersion

when cleaning. (Partial cleaning of the

PC board and soldered terminals is

possible.)

(1) Screen-printing method is

recommended for cream solder printing.

(2) Use the recommended foot pattern for

cream solder printing (screen thickness:

0.12 mm).

(3) The metal mask opening ratio for the

COM contact (one) and NO contacts

(two) must be 75%.

(4) When applying the different thickness

of a screen, please consult us.

(5) The following diagram shows the

recommended reflow soldering

temperature profile.

5. After PC board mounting

1) Warping of the PC board should be no

more than 0.03 mm for the entire

connector length.

5) Please include notes to the following

effect in your user manuals.

The recommended conditions for the

reflow temperature profile

2) When assembling PC boards or

storing them in block assemblies, make

sure that undue weight is not exerted on

a stacked socket.

3) Be sure not to allow external pressure

to act on sockets when assembling PC

boards or moving in block assemblies.

6. Handling single components

1) Make sure not to drop or allow parts to

fall from work bench

6) The card ejection protection lock does

not work for MMC.

7) The socket does not have a wrong

insertion protection structure for MMC.

Be careful about the insertion direction.

8) If an MMC is inserted, it is possible

that a short circuit between the socket’s

signal contacts No. 7 and 8 and the

MMC’s contact No. 7 may be caused.

Temperature

Peak temperature

250°C max.

180 to 200°C

Preheating

155 to 165°C

60 to 120 sec.

Within 30 sec.

Time

panasonic-electric-works.net/ac

PANASONIC [ PANASONIC ]

PANASONIC [ PANASONIC ]