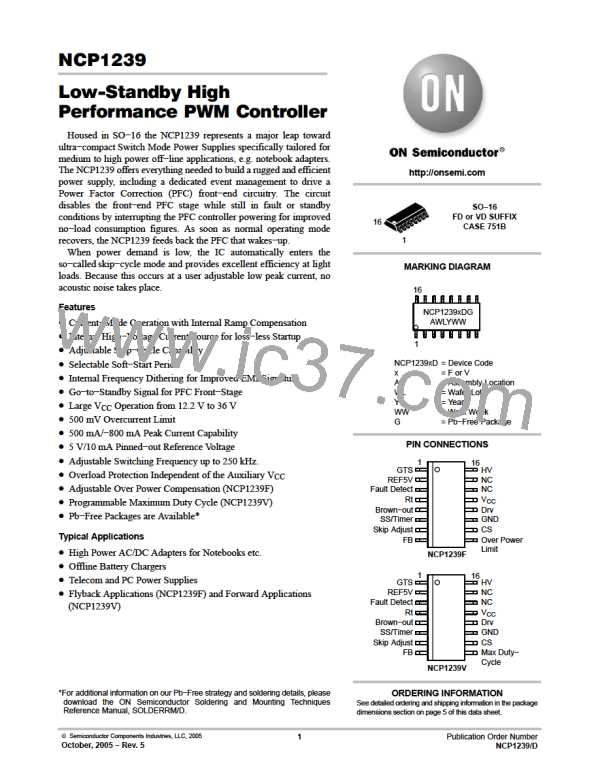

NCP1239

Startup Sequence

As soon as V

reaches 16.4 V, driving pulses are

CC

When the power supply is first connected to the mains

outlet, the internal current source (typically 3.6 mA) is

delivered on Pin 12 and the auxiliary winding grows up the

pin. Because the output voltage is below the target (the

V

CC

biased and charges up the V capacitor. When the voltage

SMPS is starting up), the feedback pin is at its maximum

voltage. A resistor divider outputs the third of the feedback

voltage that forms the current setpoint. This setpoint is

clamped and the limitation level slowly increases until it

reaches 0.9V during the soft start time. In nominal operation,

the setpoint clamp keeps equal to 0.9 V (refer to Figure 36).

As soon as the feedback voltage is high enough to activate

the 0.9 V setpoint clamp (during the startup period but also

anytime an overload occurs), an internal error flag is

asserted, testifying that the system is pushed to the

maximum power. At that moment, a 100 ms time period

CC

on this V capacitor reaches the V

level (typically

CC

CCON

16.4 V), the current source turns off and no longer wastes

any power. At this time, the energy stored by the V

CC

capacitor serves to supply the controller and the auxiliary

supply is supposed to take over before V collapses below

CC

V . Figure 35 shows the internal arrangement of this

CCOFF

structure:

16

13

10

HV

16.4 V /

11.2 V

(typically, with C =390 nF that also corresponds to 7.5 ms

pin6

+

−

3.6 mA/0

soft −start) starts while a logic block observes this error flag.

If the error flag keeps asserted all along the 100ms period,

then the controller assumes that the power supply really

undergoes a fault condition and immediately stops all pulses

to enter a safe burst operation. The 100 ms timer enables to

distinguish a startup phase (shorter than 100 ms) from an

overload condition. If the error flag is released before the

100 ms period has elapsed, the controller concludes that no

error is present and resets the timer to use it for other

purposes (e.g. frequency dithering).

CV

Aux

CC

The current source brings VCC above 16.4 V and then turns off

Figure 35.

to

Vdd

/ 3

Standby Management

(Skipping, GTS)

CLK

S

20k

8

Q

Q

Vin

Feedback

R

Soft−Start

oscillator

0.9 V

Current Sense

Comparator

−

+

Ramp Compensation

Rramp

Rcomp

LEB

LEB

10

Current Sense

Rsense

Pin 5 (Brown−Out)

Overcurrents Compensation

Over Power

Comparator

9

+

−

Over Power

Limit

+

500 mV

Pin 10 monitors the power switch current and compares it to the current setpoint (one third of the feedback voltage). The

current setpoint is limited by the soft−start during the power−on sequence and permanently clamped to 0.9 V In the

NCP1239F, a second pin (Pin 9) monitors the current to clamp the power.

Figure 36. Current Control

http://onsemi.com

17

ONSEMI [ ONSEMI ]

ONSEMI [ ONSEMI ]