MC10H109

PACKAGE DIMENSIONS

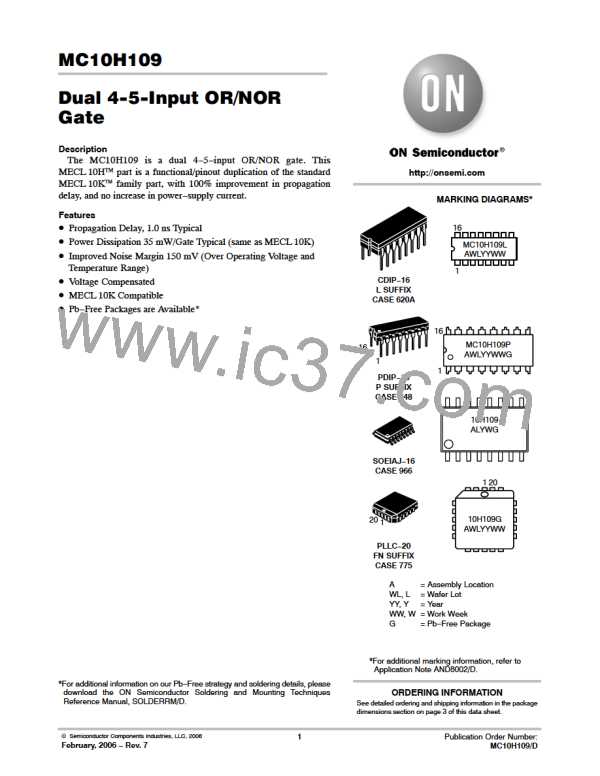

20 LEAD PLLC

CASE 775−02

ISSUE E

M

S

S

N

0.007 (0.180)

T L−M

B

Y BRK

−N−

S

S

N

0.007 (0.180) M T L−M

U

D

D

−L−

−M−

Z

W

20

1

S

S

S

N

0.010 (0.250)

T L−M

G1

X

V

VIEW D−D

M

M

S

S

S

S

A

R

0.007 (0.180)

0.007 (0.180)

T L−M

N

N

Z

T L−M

M

S

S

N

0.007 (0.180)

T L−M

H

C

K1

E

K

0.004 (0.100)

G

−T− SEATING

PLANE

J

M

S

S

N

0.007 (0.180)

T L−M

F

VIEW S

G1

VIEW S

S

S

S

0.010 (0.250)

T L−M

N

NOTES:

INCHES

MILLIMETERS

1. DIMENSIONS AND TOLERANCING PER ANSI Y14.5M,

1982.

DIM

A

B

C

E

MIN

MAX

0.395

0.395

0.180

0.110

0.019

MIN

9.78

9.78

4.20

2.29

0.33

MAX

10.03

10.03

4.57

2.79

0.48

0.385

0.385

0.165

0.090

0.013

2. DIMENSIONS IN INCHES.

3. DATUMS −L−, −M−, AND −N− DETERMINED WHERE TOP

OF LEAD SHOULDER EXITS PLASTIC BODY AT MOLD

PARTING LINE.

4. DIMENSION G1, TRUE POSITION TO BE MEASURED AT

DATUM −T−, SEATING PLANE.

F

G

H

J

K

R

U

V

W

X

Y

0.050 BSC

1.27 BSC

5. DIMENSIONS R AND U DO NOT INCLUDE MOLD FLASH.

ALLOWABLE MOLD FLASH IS 0.010 (0.250) PER SIDE.

6. DIMENSIONS IN THE PACKAGE TOP MAY BE SMALLER

THAN THE PACKAGE BOTTOM BY UP TO 0.012 (0.300).

DIMENSIONS R AND U ARE DETERMINED AT THE

OUTERMOST EXTREMES OF THE PLASTIC BODY

EXCLUSIVE OF MOLD FLASH, TIE BAR BURRS, GATE

BURRS AND INTERLEAD FLASH, BUT INCLUDING ANY

MISMATCH BETWEEN THE TOP AND BOTTOM OF THE

PLASTIC BODY.

7. DIMENSION H DOES NOT INCLUDE DAMBAR

PROTRUSION OR INTRUSION. THE DAMBAR

PROTRUSION(S) SHALL NOT CAUSE THE H DIMENSION

TO BE GREATER THAN 0.037 (0.940). THE DAMBAR

INTRUSION(S) SHALL NOT CAUSE THE H DIMENSION TO

BE SMALLER THAN 0.025 (0.635).

0.026

0.020

0.025

0.350

0.350

0.042

0.042

0.042

0.032

−−−

−−−

0.356

0.356

0.048

0.048

0.056

0.66

0.51

0.64

8.89

8.89

1.07

1.07

1.07

−−−

2

0.81

−−−

−−−

9.04

9.04

1.21

1.21

1.42

0.50

10

−−− 0.020

Z

2

10

0.330

−−−

_

_

_

_

G1 0.310

K1 0.040

7.88

1.02

8.38

−−−

http://onsemi.com

4

ONSEMI [ ONSEMI ]

ONSEMI [ ONSEMI ]