Smallest TEC Power Drivers for

Optical Modules

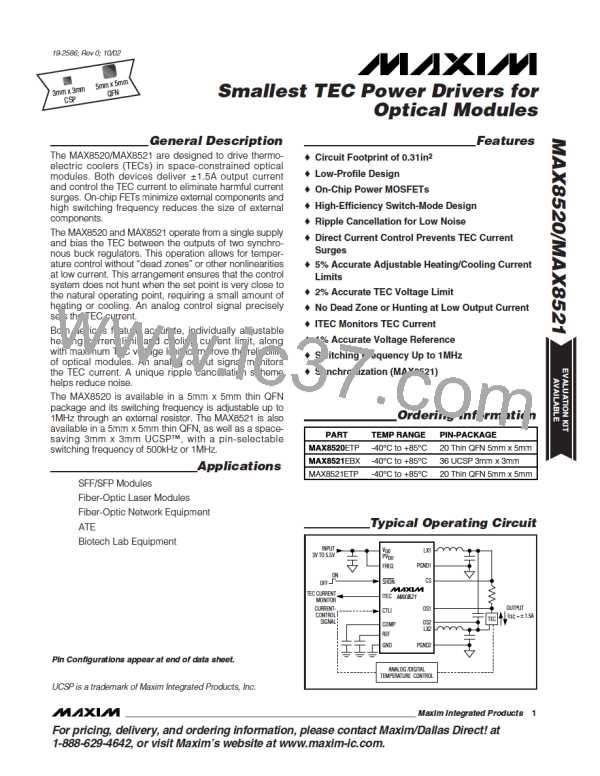

Detailed Description

Table 1. TEC Connection for Figure 1

The MAX8520/MAX8521 TEC drivers consist of two

switching buck regulators that operate together to directly

control the TEC current. This configuration creates a

differential voltage across the TEC, allowing bidirectional

TEC current for controlled cooling and heating. Controlled

cooling and heating allow accurate TEC temperature con-

trol to within 0.01°C. The voltage at CTLI directly sets

the TEC current. An external thermal- control loop is typi-

cally used to drive CTLI. Figures 1 and 2 show examples

of the thermal control-loop circuit.

TEC CONNECTION

Heating mode

THERMISTOR

PTC

Cooling mode

NTC

Table 2. TEC Connection for Figure 2

TEC CONNECTION

Heating mode

THERMISTOR

NTC

Cooling mode

PTC

Ripple Cancellation

Switching regulators like those used in the MAX8520/

MAX8521 inherently create ripple voltage on the output.

The dual regulators in the MAX8520/MAX8521 switch in

phase and provide complementary in-phase duty

cycles so ripple waveforms at the TEC are greatly

reduced. This feature suppresses ripple currents and

electrical noise at the TEC to prevent interference with

the laser diode.

Current Monitor Output

ITEC provides a voltage output proportional to the TEC

current (I

details:

). See the Functional Diagram for more

TEC

V

ITEC

= 1.5V +(8 ✕ (VOS1-VCS))

Reference Output

The MAX8520/MAX8521 include an on-chip voltage ref-

erence. The 1.50V reference is accurate to 1% over

temperature. Bypass REF with 0.1µF to GND. REF can

be used to bias an external thermistor for temperature

sensing as shown in Figures 1 and 2.

Switching Frequency

For the MAX8521, FREQ sets the switching frequency of

the internal oscillator. With FREQ = GND, the oscillator

frequency is set to 500kHz. The oscillator frequency is

Thermal and Fault-Current Protection

The MAX8520/MAX8521 provide fault-current protection

in either FET by turning off both high-side and low-side

FETs when the peak current exceeds 3A in either FET. In

addition, thermal-overload protection limits the total

power dissipation in the chip. When the device’s die junc-

tion temperature exceeds +165°C, an on-chip thermal

sensor shuts down the device. The thermal sensor turns

the device on again after the junction temperature cools

down by 15°C.

1MHz when FREQ = V

.

DD

For the MAX8520, connect a resistor (R

in Figure 2)

EXT

from FREQ to GND. Choose R

= 60kΩ for 1MHz

EXT

operation, and R

= 150kΩ for 500kHz operation. For

EXT

any intermediary frequency between 500kHz and

1MHz, use the following equation to find the value of

R

value needed for V

= 5V:

EXT

DD

1

fs

1

3

R

= 90 ×

−

EXT

Design Procedures

where R

is the resistance given in kΩ, and fs is the

EXT

Duty-Cycle Range Selection

By design, the MAX8520/MAX8521 are capable of oper-

ating from 0% to 100% duty cycle, allowing both LX out-

puts to enter dropout. However, as the LX pulse width

narrows, accurate duty-cycle control becomes difficult.

This can result in a low-frequency noise appearing at the

TEC output (typically in the 20kHz to 50kHz range). While

this noise is typically filtered out by the low thermal-loop

bandwidth, for best results, operate the PWM with a pulse

width greater than 200ns. For a 500kHz application, the

recommended duty-cycle range is from 10% to 90%. For

a 1MHz application, it is from 20% to 80%.

desired frequency given in MHz. Note that for V

<

DD

5V, the frequency is reduced slightly, to the extent of

about 7% when V reaches 3V. This should be taken

DD

into consideration when selecting the value for R

a known supply voltage.

at

EXT

Voltage and Current-Limit Setting

Both the MAX8520 and MAX8521 provide control of the

maximum differential TEC voltage. Applying a voltage

to MAXV limits the maximum voltage across the TEC.

The voltage at MAXIP and MAXIN sets the maximum

positive and negative current through the TEC. These

current limits can be independently controlled.

10 ______________________________________________________________________________________

MAXIM [ MAXIM INTEGRATED PRODUCTS ]

MAXIM [ MAXIM INTEGRATED PRODUCTS ]