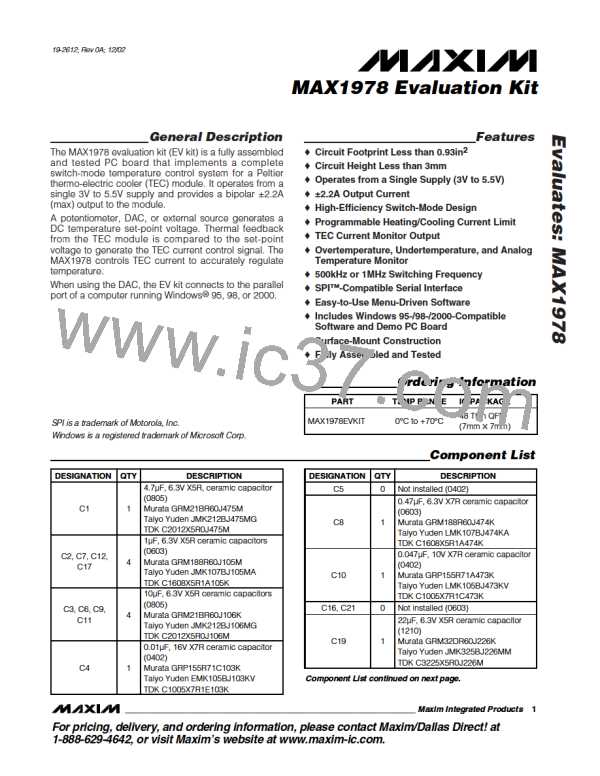

MAX1978 Evaluation Kit

The program starts with ratio = 0.5. This sets the DAC

The utility handles the data only in byte (8-bit) format.

Data longer than a byte must be handled as multiple

bytes. For example, a 16-bit word must be broken into

two 8-bit bytes. To write data to the slave device, enter

the data into the field labeled “Data bytes to be written:”

Each data byte should be hexadecimal, prefixed by 0x,

and separated with a comma. Press the Send Now

button to write the data to the slave.

output to 0.75V, which corresponds to +25°C.

A ratio of 0.67 sets the DAC output to 1V, which corre-

sponds to approximately +10°C. A ratio of 0.33 sets the

DAC output to 0.5V, or approximately +40°C. The slope

is approximately -14mV/°C for a typical NTC.

General-Purpose SPI Utility

There are two methods for communicating with the

MAX5144 DAC: through the user-interface panel or

through the general-purpose SPI utility. This utility

(Figure 3) configures SPI parameters such as clock

polarity (CPOL), clock phase (CPHA), and chip-select

(CS) polarity. The fields where pin numbers are

required apply to the pins of the parallel port connector.

To read data from the slave device, the field “Data

bytes to be written:” must contain hexadecimal values.

Include the same number of bytes as to be read from

the slave.

Note: The MAX5144 is a write-only device and cannot

be read.

INTO

CTLI

1.5V

REF

JU2

SET POINT

DAC

DIFOUT

INT-

1.5V

REF

FB+

JU4

50R

1.5V

REF

INTEGRATOR

OS2

OS1

TEC+

R

20kΩ

PWM

SECTION

THERM

R

TEC-

N

P

1.5V

REF

FB-

50R

10kΩ

MAX1978

CHOPPER AMP

10kΩ THERMISTOR

Figure 1. Thermal-Loop Functional Diagram for the MAX1978 EV Kit

6

_______________________________________________________________________________________

MAXIM [ MAXIM INTEGRATED PRODUCTS ]

MAXIM [ MAXIM INTEGRATED PRODUCTS ]