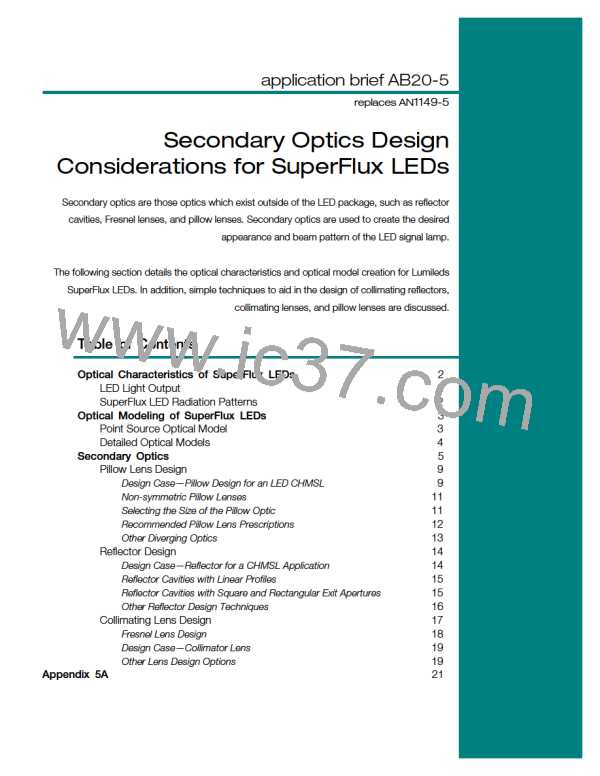

Design Case—Collimator Lens

Consider the case where a lens will be used to collimate the

light from an HPWT-DH00 source, and a pillow optic cover

lens will be used to form the final radiation pattern. Clear

PMMA (n = 1.49) will be used as the lens material. The LED

spacing is 20 mm and the spacing from the top of the PCB

to the top surface of the lens must be less than 25 mm.

The total included angle of the HPWT-DH00 is 70°,

therefore, to capture 90% of the light from the LED, the lens

must span 35°?from the optical axis, and fill a 20 mm X 20

mm area. The combination of included angle, lamp depth,

and LED spacing define the necessary items to determine f.

Figure 5.30 shows a cross-section of the lamp described

above.

To optimize collection efficiency, R1 must be greater than R2.

By placing the flatter surface closer to the LED, the ray

bending is more equally shared between the two lens surfaces.

However, if R2 becomes too small, the lens will be too thick

and difficult to manufacture. A good compromise between

these two competing factors is R1 = 24 mm, and R2 = 18 mm.

Figure 5.31 shows a cross-section of an LED signal lamp with

this dual-convex lens design.

Examining the geometry shown in Figure 5.30, the desired

focal length, f, is approximately 15.3mm. A lens of this

power will be a dual-convex, and R1 and R2 can now be

calculated using the following equation:

Consider a case with a plano-convex lens (R =

19mm) where an aperture diameter of 25 mm

is desired for use as a collimating lens. This lens

will be too thick to properly injection mold

(greater than 6 mm), so a Fresnel design will be

used with a maximum height of 4 mm. The

resulting design will have three steps, as shown

in Figure 5.32.

efficient than spherical forms. However, the

design of these types of lenses is more complex

and generally requires optical modeling software

and accurate optical models of the LED.

Another class of lens exists which couple the

principles of refraction and total internal reflection

(TIR). These lenses are commonly referred to as

reflective/refractive, or catadioptric lenses. Lenses

designed by Fresnel over 100 years ago for light

houses contained such TIR faces for improved

efficiency. An example of a catadioptric lens is

shown in Figure 5.34.

Convex-Fresnel lenses can be designed in

which a large radius (low curvature) lens is used

on the LED side, and a Fresnel-type lens with a

smaller radius (more curvature) is used on the

other side as shown in Figure 5.33.

This type of lens is useful when refractive lens

designs cannot efficiently bend the light rays at

the required angle. By combining reflection and

refraction into a single optical element, a very

powerful and efficient lens can be designed. TIR

is most efficient when incident rays are nearly

tangential, where as refraction is most efficient

when the rays are close to the normal.

Other Lens Design Options

In this section we have discussed only spherical

lens designs. Spherical lenses are easily

designed, specified, and checked; but may not

be the most efficient collimator due to spherical

aberrations. Other lens designs, such as

hyperbolic-planar, sphero-elliptic, and free-form

lenses can be designed which may be more

19

LUMILEDS [ LUMILEDS LIGHTING COMPANY ]

LUMILEDS [ LUMILEDS LIGHTING COMPANY ]