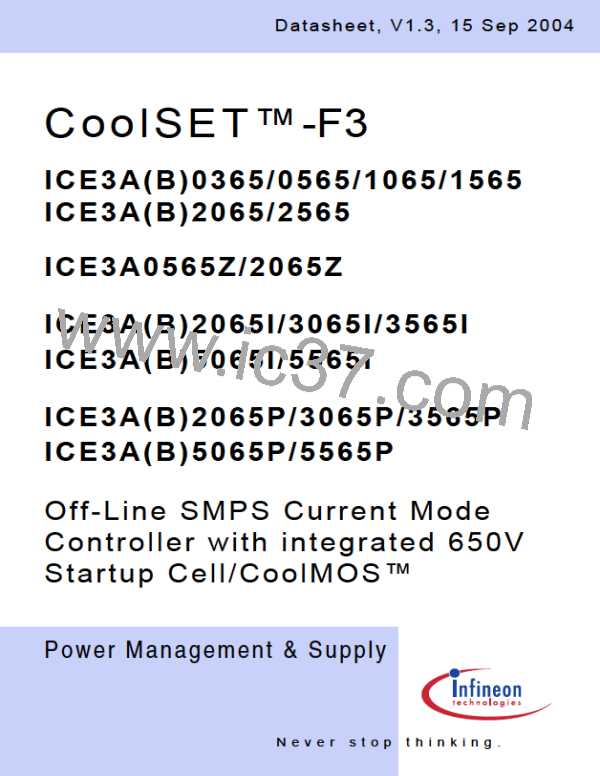

CoolSET™-F3

Functional Description

3.4.3

Gate Driver

3.4

PWM Section

0.72

PWM Section

Oscillator

Duty Cycle

max

VCC

PWM-Latch

Clock

1

Gate

Soft Start

FF1

Comparator

CoolMOS™

Gate Driver

&

S

R

1

PWM

Comparator

Q

G8

G9

Gate Driver

Current

Limiting

Figure 10

Gate Driver

The driver-stage is optimized to minimize EMI and to

provide high circuit efficiency. This is done by reducing

the switch on slope when exceeding the internal

CoolMOS™ threshold. This is achieved by a slope

control of the rising edge at the driver’s output (see

Figure 10).

Gate

Figure 9

3.4.1

PWM Section

Oscillator

The oscillator generates

switching frequency of ICE3Axx65x is fOSC = 100kHz

and for ICE3Bxx65x fOSC 67kHz. resistor, a

a fixed frequency. The

(internal) VGate

=

A

capacitor and a current source and current sink which

determine the frequency are integrated. The charging

and discharging current of the implemented oscillator

capacitor are internally trimmed, in order to achieve a

very accurate switching frequency. The ratio of

controlled charge to discharge current is adjusted to

reach a maximum duty cycle limitation of Dmax=0.72.

ca. t = 130ns

5V

t

3.4.2

PWM-Latch FF1

The oscillator clock output provides a set pulse to the

PWM-Latch when initiating the external Power Switch

conduction. After setting the PWM-Latch can be reset

by the PWM comparator, the Soft Start comparator or

the Current-Limit comparator. In case of resetting, the

driver is shut down immediately.

Figure 11

Gate Rising Slope

Thus the leading switch on spike is minimized. When

the integrated CoolMOS™ is switched off, the falling

shape of the driver is slowed down when reaching 2V

to prevent an overshoot below ground. Furthermore the

driver circuit is designed to eliminate cross conduction

of the output stage. During powerup when VCC is

below the undervoltage lockout threshold VVCCoff, the

output of the Gate Driver is low to disable power

transfer to the seconding side.

Version 1.3

13

15 Sep 2004

INFINEON [ Infineon ]

INFINEON [ Infineon ]