As mentioned earlier, once a heat sink has been selected, the

complete design should be tested under worst-case load and

signal conditions to ensure proper thermal protection. Any

tendency to activate the thermal protection circuitry may

indicate inadequate heat sinking.

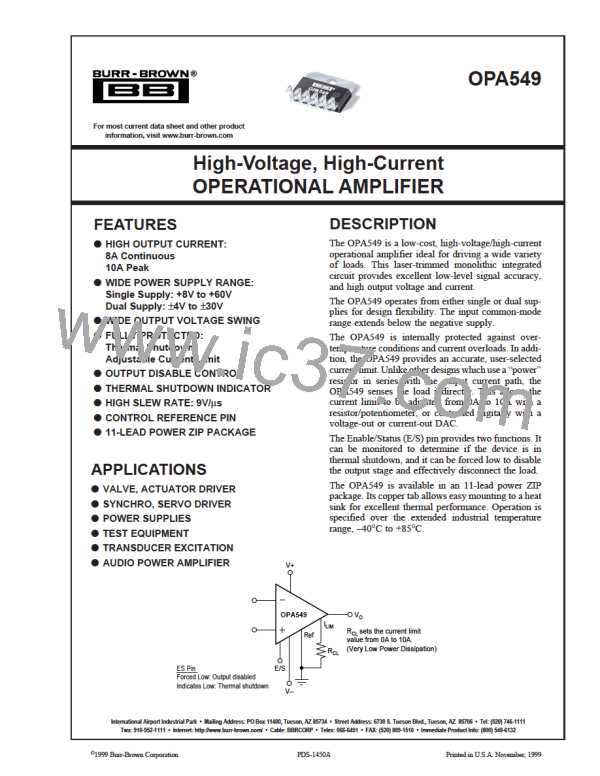

OUTPUT PROTECTION

Reactive and EMF-generating loads can return load current

to the amplifier, causing the output voltage to exceed the

power supply voltage. This damaging condition can be

avoided with clamp diodes from the output terminal to the

power supplies as shown in Figure 8. Schottky rectifier

diodes with a 8A or greater continuous rating are recom-

mended.

The tab of the 11-lead power ZIP package is electrically

connected to the negative supply, V–. It may be desirable to

isolate the tab of 11-lead power ZIP package from its

mounting surface with a mica (or other film) insulator. For

lowest overall thermal resistance, it is best to isolate the

entire heat sink/OPA549 structure from the mounting sur-

face rather than to use an insulator between the semiconduc-

tor and heat sink.

VOLTAGE SOURCE APPLICATION

Figure 9 illustrates how to use the OPA549 to provide an

accurate voltage source with only three external resistors.

First, the current limit resistor, RCL , is chosen according to

the desired output current. The resulting voltage at the ILIM

pin is constant and stable over temperature. This voltage,

VCL, is connected to the non-inverting input of the op amp

and used as a voltage reference, thus eliminating the need for

an external reference. The feedback resistors are selected to

gain VCL to the desired output voltage level.

OUTPUT STAGE COMPENSATION

The complex load impedances common in power op amp

applications can cause output stage instability. For normal

operation, output compensation circuitry is typically not

required. However, for difficult loads or if the OPA549 is

intended to be driven into current limit, an R/C network may

be required. Figure 8 shows an output R/C compensation

(snubber) network which generally provides excellent sta-

bility.

PROGRAMMABLE POWER SUPPLY

A programmable source/sink power supply can easily be

built using the OPA549. Both the output voltage and output

current are user-controlled. Figure 10 shows a circuit using

potentiometers to adjust the output voltage and current while

Figure 11 uses digital-to-analog converters. An LED con-

nected to the E/S pin through a logic gate indicates if the

OPA549 is in thermal shutdown.

A snubber circuit may also enhance stability when driving

large capacitive loads (>1000pF) or inductive loads (motors,

loads separated from the amplifier by long cables). Typi-

cally, 3Ω to 10Ω resistors in series with 0.01µF to 0.1µF

capacitors is adequate. Some variations in circuit values

may be required with certain loads.

R1

R2

V+

V+

R2

R1

5kΩ

R2

20kΩ

G = –

= –4

R1

VIN

VO = VCL (1 + R2/R1)

15800 (4.75V)

4.75V

7500Ω

D1

Ref

IO

=

VCL

7500Ω + RCL

OPA549

ILIM

10Ω

(Carbon)

D2

Motor

V–

0.01µF

V–

D1, D2 : Schottky Diodes

0.01µF

RCL

(Optional, for noisy

environments)

Uses voltage developed at ILIM pin

as a moderately accurate reference

voltage.

For Example:

FIGURE 8. Motor Drive Circuit.

If ILIM = 7.9A, RCL = 2kΩ

2kΩ • 4.75V

VCL

=

= 1V

(2kΩ + 7500Ω)

10

1

Desired VO = 10V,G =

= 10

R1 = 1kΩ and R2 = 9kΩ

FIGURE 9. Voltage Source.

®

OPA549

12

BB [ BURR-BROWN CORPORATION ]

BB [ BURR-BROWN CORPORATION ]