in a complete design (including heat sink) increase the

ambient temperature until the thermal protection is trig-

gered. Use worst-case load and signal conditions. For good

reliability, thermal protection should trigger more than 35°C

above the maximum expected ambient condition of your

application. This produces a junction temperature of 125°C

at the maximum expected ambient condition.

screw torque, insulating material used (if any), and thermal

joint compound used (if any) also affect θCH. A typical θCH

for a mounted 11-lead power ZIP package is 0.5°C/W. Now

we can solve for θHA

:

θHA = [(TJ – TA)/PD] – θJC – θCH

θHA = [(125°C – 40°C)/10W] – 1.4°C/W – 0.5°C/W

The internal protection circuitry of the OPA549 was de-

signed to protect against overload conditions. It was not

intended to replace proper heat sinking. Continuously run-

ning the OPA549 into thermal shutdown will degrade reli-

ability.

θHA = 6.6°C/W

To maintain junction temperature below 125°C, the heat

sink selected must have a θHA less than 6.6°C/W. In other

words, the heat sink temperature rise above ambient must be

less than 66°C (6.6°C/W • 10W). For example, at 10W

Thermalloy model number 6396B has a heat sink tempera-

ture rise of 56°C (θHA = 56°C/10W = 5.6°C/W), which is

below the required 66°C required in this example. Thermalloy

model number 6399B has a sink temperature rise of 33°C

(θHA = 33°C/10W = 3.3°C/W), which is also below the

required 66°C required in this example. Figure 7 shows

power dissipation versus ambient temperature for a 11-lead

power ZIP package with the Thermalloy 6396B and 6399B

heat sinks.

AMPLIFIER MOUNTING AND HEAT SINKING

Most applications require a heat sink to assure that the

maximum operating junction temperature (125°C) is not

exceeded. In addition, the junction temperature should be

kept as low as possible for increased reliability. Junction

temperature can be determined according to the Equations:

TJ = TA + PD θJA

(4)

(5)

where

θJA = θJC + θCH + θHA

TJ = Junction Temperature (°C)

TA = Ambient Temperature (°C)

PD = Power Dissipated (W)

30

PD = (TJ (max) – TA)/ θJA

(TJ (max) – 150°C)

θJC = Junction-to-Case Thermal Resistance (°C/W)

θCH = Case-to-Heat Sink Thermal Resistance (°C/W)

θHA = Heat Sink-to-Ambient Thermal Resistance (°C/W)

with Thermalloy 6399B

20

Heat Sink,

θ

JA = 5.2°C/W

θJA

=

Junction-to-Air Thermal Resistance (°C/W)

Figure 7 shows maximum power dissipation versus ambient

temperature with and without the use of a heat sink. Using

a heat sink significantly increases the maximum power

dissipation at a given ambient temperature as shown.

with Thermalloy 6396B

Heat Sink, JA = 7.5°C/W

θ

10

0

with No Heat Sink,

θ

JA = 30°C/W

The challenge in selecting the heat sink required lies in

determining the power dissipated by the OPA549. For dc

output, power dissipation is simply the load current times the

voltage developed across the conducting output transistor,

PD = IL (VS – VO). Other loads are not as simple. Consult

Application Bulletin AB-039 for further insight on calculat-

ing power dissipation. Once power dissipation for an appli-

cation is known, the proper heat sink can be selected.

0

25

50

75

100

125

Ambient Temperature (°C)

Thermalloy 6396B

assume

θ HA = 5.6°C/W

θ CH = 0.5°C/W

θ JC = 1.4°C/W

θ JA = 7.5°C/W

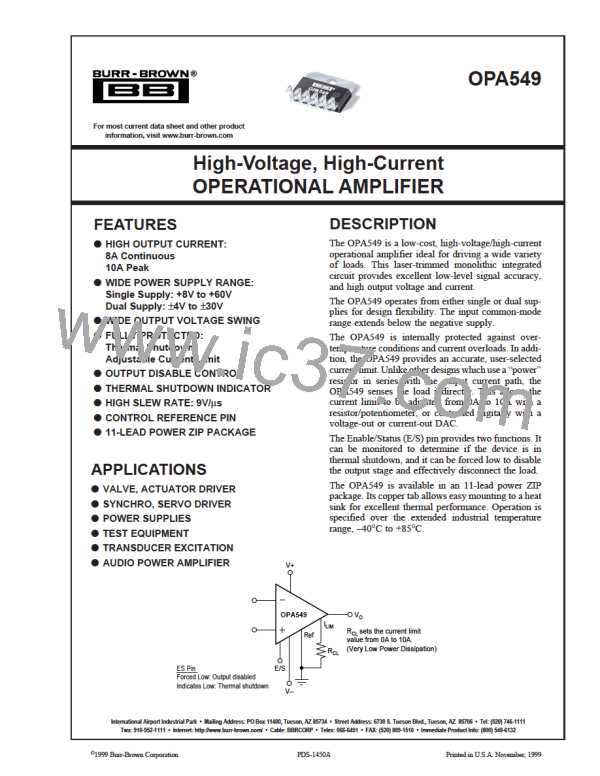

OPA549

Thermalloy 6396B

assume

θ HA = 3.3°C/W

θ CH = 0.5°C/W

θ JC = 1.4°C/W

θ JA = 5.2°C/W

Heat Sink Selection Example—An 11-lead power ZIP

package is dissipating 10 Watts. The maximum expected

ambient temperature is 40°C. Find the proper heat sink to

keep the junction temperature below 125°C (150°C minus

25°C safety margin).

OPA549

FIGURE 7. Maximum Power Dissipation vs Ambient

Temperature.

Combining Equations (4) and (5) gives:

Another variable to consider is natural convection versus

forced convection air flow. Forced-air cooling by a small fan

can lower θCA (θCH + θHA ) dramatically. Some heat sink

manufacturers provide thermal data for both of these cases.

Heat sink performance is generally specified under idealized

conditions that may be difficult to achieve in an actual

application. For additional information on determining heat

sink requirements, consult Application Bulletin AB-038.

TJ = TA + PD ( θJC + θCH + θHA

)

(6)

TJ, TA, and PD are given. θJC is provided in the Specifica-

tions Table, 1.4°C/W (dc). θCH can be obtained from the heat

sink manufacturer. Its value depends on heat sink size, area,

and material used. Semiconductor package type, mounting

®

11

OPA549

BB [ BURR-BROWN CORPORATION ]

BB [ BURR-BROWN CORPORATION ]