6

SMT Assembly

passes through one or more

Assembly Information

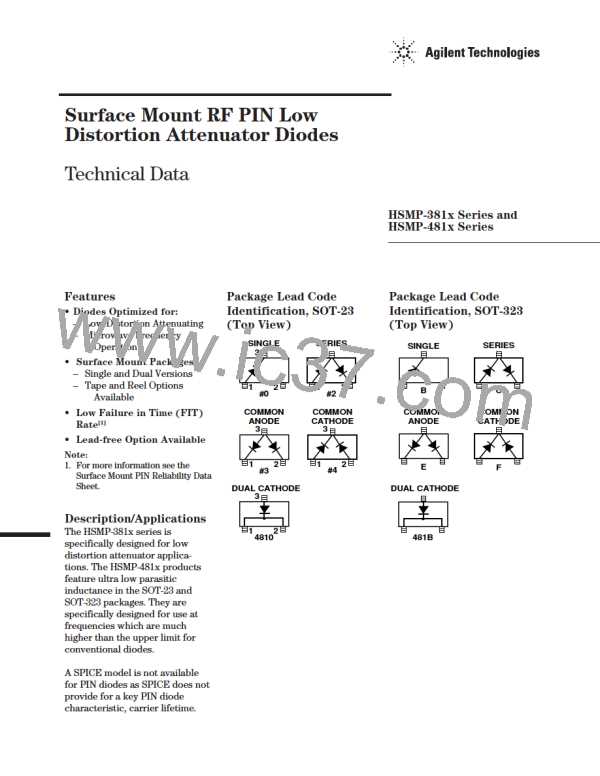

SOT-323 PCB Footprint

Reliable assembly of surface

mount components is a complex

process that involves many

material, process, and equipment

factors, including: method of

heating (e.g., IR or vapor phase

reflow, wave soldering, etc.)

circuit board material, conductor

thickness and pattern, type of

solder alloy, and the thermal

conductivity and thermal mass of

components. Components with a

preheat zones. The preheat zones

increase the temperature of the

board and components to prevent

thermal shock and begin evaporat-

ing solvents from the solder paste.

The reflow zone briefly elevates

the temperature sufficiently to

produce a reflow of the solder.

A recommended PCB pad layout

for the miniature SOT-323 (SC-70)

package is shown in Figure 12

(dimensions are in inches). This

layout provides ample allowance

for package placement by auto-

mated assembly equipment

without adding parasitics that

could impair the performance.

The rates of change of tempera-

ture for the ramp-up and cool-

down zones are chosen to be low

0.026

low mass, such as the SOT-323/-23 enough to not cause deformation

package, will reach solder reflow

temperatures faster than those

with a greater mass.

of the board or damage to compo-

nents due to thermal shock. The

maximum temperature in the

0.07

reflow zone (T

) should not

MAX

Agilent’s diodes have been

qualified to the time-temperature

profile shown in Figure 14. This

profile is representative of an IR

reflow type of surface mount

assembly process.

exceed 235°C.

0.035

These parameters are typical for a

surface mount assembly process

for Agilent diodes. As a general

guideline, the circuit board and

components should be exposed

only to the minimum tempera-

tures and times necessary to

achieve a uniform reflow of

solder.

0.016

Figure 12. PCB Pad Layout

(dimensions in inches).

After ramping up from room

temperature, the circuit board

with components attached to it

(held in place with solder paste)

SOT-23 PCB Footprint

0.037

0.95

0.037

0.95

250

200

TMAX

0.079

2.0

0.035

0.9

150

Reflow

Zone

0.031

0.8

100

inches

DIMENSIONS IN

mm

Preheat

Zone

Cool Down

Zone

50

0

Figure 13. PCB Pad Layout.

0

60

120

180

240

300

TIME (seconds)

Figure 14. Surface Mount Assembly Profile.

AGILENT [ AGILENT TECHNOLOGIES, LTD. ]

AGILENT [ AGILENT TECHNOLOGIES, LTD. ]