ADSY8401

PCB DESIGN FOR OPTIMIZED THERMAL PERFORMANCE

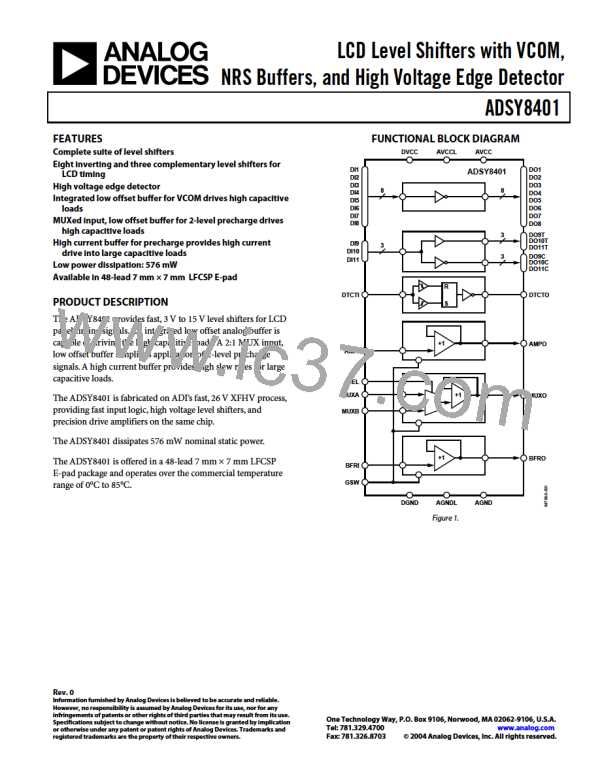

Solder Masking

The total maximum power dissipation of the ADSY8401 is

partly load-dependent. In a typical 60 Hz XGA system, the total

maximum power dissipation is ≈ 1 W. The ADSY8401 package

is designed to provide superior thermal characteristics, partly

through the exposed die paddle on the bottom surface of the

package. To take full advantage of this feature, the exposed

paddle must be in direct thermal contact with the PCB, which

then serves as a heat sink.

To minimize the formation of solder voids due to solder flowing

into the via holes (solder wicking), the via diameter should be

small. Solder masking of the via holes on the top layer of the

PCB plugs the via holes, inhibiting solder flow into the holes. To

optimize the thermal pad coverage, the solder mask diameter

should be no more than 0.1 mm larger than the via diameter.

Table 7. Recommended Solder Mask Dimensions

Solder Mask

Top layer

Pads

Dimensions

A thermally effective PCB must incorporate a thermal pad and

a thermal via structure. The thermal pad provides a solderable

contact surface on the top surface of the PCB. The thermal via

structure provides a thermal path to the inner and bottom

layers of the PCB to remove heat.

Set by customer’s PCB design rules

0.25 mm diameter circular mask centered

on the vias

Thermal vias

Bottom layer

Set by customer’s PCB design rules

Thermal Pad Design

To minimize thermal performance degradation of production

PCBs, the contact area between the thermal pad and the PCB

should be maximized. Therefore, the size of the thermal pad on

the top PCB layer should match the exposed paddle. The second

thermal pad of the same size should be placed on the bottom

side of the PCB. At least one thermal pad should be in direct

thermal contact with an external plane such as AVCC or GND.

7mm

Thermal Via Structure Design

Effective heat transfer from the top to the inner and bottom

layers of the PCB requires thermal vias incorporated into the

thermal pad design. Thermal performance increases logarith-

mically with the number of vias. Near optimum thermal

performance of production PCBs is attained only when tightly

spaced thermal vias are placed on the full extent of the thermal

pad.

LAND PATTERN–TOP LAYER

Table 6. Recommended Land Pattern Dimensions

Land Pattern

Dimensions

Top and Bottom Layers

Pad size

Pad pitch

0.5 mm × 0.25 mm

0.5 mm

Thermal pad size

Thermal via structure

5.25 mm × 5.25 mm

0.25 mm diameter vias on

0.5 mm grid

LAND PATTERN–BOTTOM LAYER

Thermal Pad and Thermal Via Connections

Thermal pads are connected to the AGND or AVCC plane. The

thermal pad on the solder side is connected to a plane. The use

of thermal spokes is not recommended when connecting the

thermal pads or via structure to the plane.

SOLDER MASK–TOP LAYER

Figure 13. PCB Layers

Rev. 0 | Page 13 of 16

ADI [ ADI ]

ADI [ ADI ]