AD73360L

DSP SPORT Interrupts

DSP

MICROPROCESSOR

If SPORT interrupts are enabled, it is important to note that the

active signals on the frame sync pins do not necessarily corre-

spond with the positions in time of where SPORT interrupts are

generated.

I

I

V

C

C

DAC

DAC

TORQUE & FLUX

CONTROL LOOP

CALCULATIONS

THREE-

PHASE

MOTOR

V

B

B

DRIVE

CIRCUITRY

I

V

A

A

On ADSP-21xx processors, it is necessary to enable SPORT

interrupts and use Interrupt Service Routines (ISRs) to handle

Tx/Rx activity, while on the TMS320CSx processors it is pos-

sible to poll the status of the Rx and Tx registers, which means

that Rx/Tx activity can be monitored using a single ISR that

would ideally be the Tx ISR as the Tx interrupt will typically

occur before the Rx ISR.

DAC

ISOLATION

AMPLIFIERS

TORQUE

SETPOINT

FLUX

SETPOINT

V

V

IN1

IN2

AD73360L

TRANSFORMATION

TO TORQUE &

FLUX

V

IN3

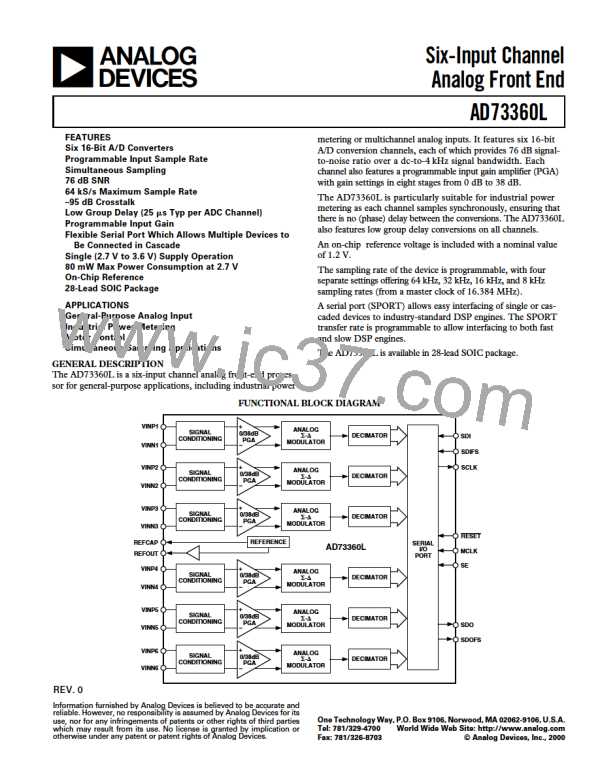

APPLICATIONS EXAMPLES

Vector Motor Control

CURRENT

V

IN4

COMPONENTS

V

IN5

The current drawn by a motor can be split into two compo-

nents: one produces torque and the other produces magnetic

flux. For optimal performance of the motor, these two compo-

nents should be controlled independently. In conventional

methods of controlling a three-phase motor, the current (or

voltage) supplied to the motor and the frequency of the drive are

the basic control variables. However, both the torque and flux

are functions of current (or voltage) and frequency. This cou-

pling effect can reduce the performance of the motor because,

for example, if the torque is increased by increasing the fre-

quency, the flux tends to decrease.

V

IN6

VOLTAGE

ATTENUATORS

Figure 30. Vector Motor Control Using the AD73360L

Industrial Power Metering

The AD73360L can be used to measure the voltage and current

in all three phases of a three-phase supply. The simultaneous

sampling architecture of the AD73360L is ideal for this applica-

tion where simultaneous sampling is critical to maintaining the

relative phase information between the three voltage and three

current phases. Figure 31 shows a block diagram of a three-

phase metering system. The VIN1, VIN2, and VIN3 channels are

used to measure the voltages in each phase (via voltage attenua-

tors). The current flowing in each phase can be detected by the

use of current-sensing isolation amplifiers, transformers or

Hall-effect sensors. VIN4, VIN5, and VIN6 are used to digitize

this information. A DSP microprocessor is used to perform

the mathematical calculations on the information provided

by the AD73360L.

Vector control of an ac motor involves controlling phase in

addition to drive and current frequency. Controlling the phase

of the motor requires feedback information on the position of

the rotor relative to the rotating magnetic field in the motor.

Using this information, a vector controller mathematically trans-

forms the three-phase drive currents into separate torque and

flux components. The AD73360L, with its six-channel simulta-

neous sampling capability, is ideally suited for use in vector

motor control applications.

I

V

C

A block diagram of a vector motor control application using the

AD73360L is shown in Figure 30. The position of the field is

derived by determining the current in each phase of the motor.

VIN1, VIN2, and VIN3 of the AD73360L are used to digitize this

information.

C

3

I

V

B

THREE-

PHASE

SUPPLY

B

2

I

V

A

A

1

Simultaneous sampling is critical to maintain the relative phase

information between the channels. A current-sensing isolation

amplifier, transformer or Hall-effect sensor is used between the

motor and the AD73360L. Rotor information is obtained by

ISOLATION

AMPLIFIERS

V

V

IN1

measuring the voltage from the three inputs to the motor. VIN4

IN5, and VIN6 of the AD73360L are used to obtain this informa-

,

IN2

V

AD73360L

V

DSP

MICROPROCESSOR

tion. A DSP microprocessor is used to perform the mathematical

transformations and control loop calculations on the informa-

tion fed back by the AD73360L.

IN3

V

V

V

IN4

IN5

IN6

VOLTAGE

ATTENUATORS

Figure 31. Three-Phase Power Metering

–24–

REV. 0

ADI [ ADI ]

ADI [ ADI ]