TMC5130A DATASHEET (Rev. 1.14 / 2017-MAY-15)

126

36 Table of Figures

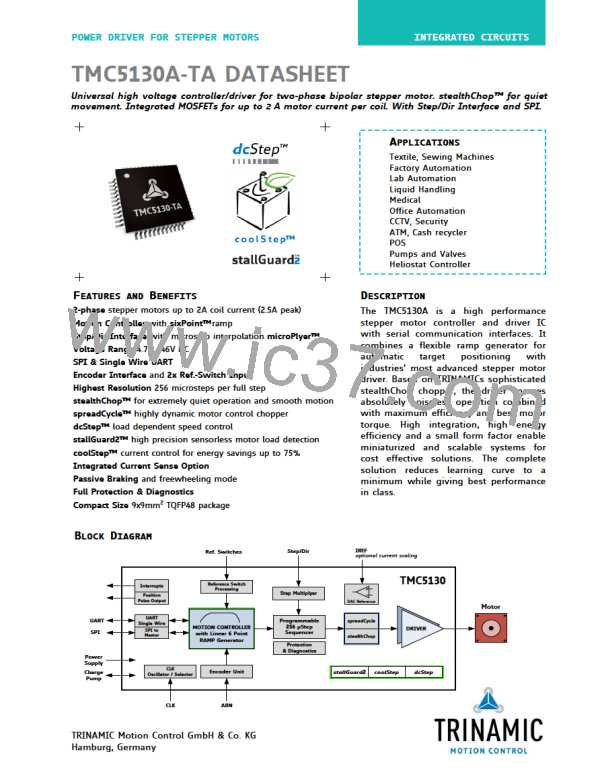

FIGURE 1.1 TMC5130A BASIC APPLICATION BLOCK DIAGRAM WITH MOTION CONTROLLER........................................................5

FIGURE 1.2 TMC5130A STEP/DIR APPLICATION DIAGRAM......................................................................................................6

FIGURE 1.3 TMC5130A STANDALONE DRIVER APPLICATION DIAGRAM.......................................................................................6

FIGURE 1.4 ENERGY EFFICIENCY WITH COOLSTEP (EXAMPLE)......................................................................................................9

FIGURE 2.1 TMC5130A-TA PACKAGE AND PINNING TQFP-EP 48 (7X7MM BODY, 9X9MM WITH LEADS)...............................10

FIGURE 3.1 STANDARD APPLICATION CIRCUIT...........................................................................................................................13

FIGURE 3.2 REDUCED NUMBER OF FILTERING COMPONENTS ......................................................................................................14

FIGURE 3.3 RDSON BASED SENSING ELIMINATES HIGH CURRENT SENSE RESISTORS..................................................................14

FIGURE 3.4 USING AN EXTERNAL 5V SUPPLY FOR DIGITAL CIRCUITRY OF DRIVER (DIFFERENT OPTIONS)..................................15

FIGURE 3.5 USING AN EXTERNAL 5V SUPPLY TO BYPASS INTERNAL REGULATOR........................................................................16

FIGURE 3.6 EXAMPLES FOR SIMPLE PRE-REGULATORS................................................................................................................16

FIGURE 3.7 5V ONLY OPERATION..............................................................................................................................................17

FIGURE 3.8 DERATING OF MAXIMUM SINE WAVE PEAK CURRENT AT INCREASED DIE TEMPERATURE...........................................18

FIGURE 3.9 SCHOTTKY DIODES REDUCE POWER DISSIPATION AT HIGH PEAK CURRENTS UP TO 2A (2.5A)................................19

FIGURE 3.10 SIMPLE ESD ENHANCEMENT AND MORE ELABORATE MOTOR OUTPUT PROTECTION................................................20

FIGURE 4.1 SPI TIMING............................................................................................................................................................23

FIGURE 5.1 ADDRESSING MULTIPLE TMC5130A VIA SINGLE WIRE INTERFACE USING CHAINING..............................................27

FIGURE 5.2 ADDRESSING MULTIPLE TMC5130A VIA THE DIFFERENTIAL INTERFACE, ADDITIONAL FILTERING FOR NAI............28

FIGURE 7.1 MOTOR COIL SINE WAVE CURRENT WITH STEALTHCHOP (MEASURED WITH CURRENT PROBE)..................................51

FIGURE 7.2 SCOPE SHOT: GOOD SETTING FOR PWM_GRAD....................................................................................................52

FIGURE 7.3 SCOPE SHOT: TOO SMALL SETTING FOR PWM_GRAD............................................................................................52

FIGURE 7.4 GOOD AND TOO SMALL SETTING FOR PWM_GRAD ..............................................................................................53

FIGURE 7.5 VELOCITY BASED PWM SCALING (PWM_AUTOSCALE=0).........................................................................................55

FIGURE 8.1 CHOPPER PHASES ...................................................................................................................................................59

FIGURE 8.2 NO LEDGES IN CURRENT WAVE WITH SUFFICIENT HYSTERESIS (MAGENTA: CURRENT A, YELLOW & BLUE: SENSE

RESISTOR VOLTAGES A AND B).........................................................................................................................................61

FIGURE 8.3 SPREADCYCLE CHOPPER SCHEME SHOWING COIL CURRENT DURING A CHOPPER CYCLE ............................................62

FIGURE 8.4 CLASSIC CONST. OFF TIME CHOPPER WITH OFFSET SHOWING COIL CURRENT..........................................................63

FIGURE 8.5 ZERO CROSSING WITH CLASSIC CHOPPER AND CORRECTION USING SINE WAVE OFFSET..........................................63

FIGURE 9.1 SCALING THE MOTOR CURRENT USING THE ANALOG INPUT......................................................................................66

FIGURE 12.1 CHOICE OF VELOCITY DEPENDENT MODES.............................................................................................................71

FIGURE 14.1 RAMP GENERATOR VELOCITY TRACE SHOWING CONSEQUENT MOVE IN NEGATIVE DIRECTION ................................75

FIGURE 14.2 ILLUSTRATION OF OPTIMIZED MOTOR TORQUE USAGE WITH TMC5130A RAMP GENERATOR................................76

FIGURE 14.3 RAMP GENERATOR VELOCITY DEPENDENT MOTOR CONTROL...................................................................................77

FIGURE 14.4 USING REFERENCE SWITCHES (EXAMPLE)..............................................................................................................78

FIGURE 15.1 FUNCTION PRINCIPLE OF STALLGUARD2...............................................................................................................80

FIGURE 15.2 EXAMPLE: OPTIMUM SGT SETTING AND STALLGUARD2 READING WITH AN EXAMPLE MOTOR................................82

FIGURE 16.1 COOLSTEP ADAPTS MOTOR CURRENT TO THE LOAD...............................................................................................85

FIGURE 17.1 STEP AND DIR TIMING, INPUT PIN FILTER .........................................................................................................87

FIGURE 17.2 MICROPLYER MICROSTEP INTERPOLATION WITH RISING STEP FREQUENCY (EXAMPLE: 16 TO 256)......................89

FIGURE 18.1 DIAG OUTPUTS IN STEP/DIR MODE ..................................................................................................................90

FIGURE 18.2 DIAG OUTPUTS WITH SD_MODE=0...................................................................................................................91

FIGURE 19.1 DCSTEP EXTENDED APPLICATION OPERATION AREA...............................................................................................92

FIGURE 19.2 VELOCITY PROFILE WITH IMPACT BY OVERLOAD SITUATION .................................................................................93

FIGURE 19.3 MOTOR MOVING SLOWER THAN STEP INPUT DUE TO LIGHT OVERLOAD. LOSTSTEPS INCREMENTED..................96

FIGURE 19.4 FULL SIGNAL INTERCONNECTION FOR DCSTEP ......................................................................................................96

FIGURE 19.5 DCO INTERFACE TO MOTION CONTROLLER – STEP GENERATOR STOPS WHEN DCO IS ASSERTED..........................97

FIGURE 20.1 LUT PROGRAMMING EXAMPLE ..............................................................................................................................98

FIGURE 22.1 OUTLINE OF ABN SIGNALS OF AN INCREMENTAL ENCODER................................................................................100

FIGURE 24.1 CURRENT SETTING AND FIRST STEPS WITH STEALTHCHOP...................................................................................104

FIGURE 24.2 TUNING STEALTHCHOP AND SPREADCYCLE.........................................................................................................105

FIGURE 24.3 MOVING THE MOTOR USING THE MOTION CONTROLLER.......................................................................................106

FIGURE 24.4 ENABLING COOLSTEP (ONLY IN COMBINATION WITH SPREADCYCLE)..................................................................107

FIGURE 24.5 SETTING UP DCSTEP...........................................................................................................................................108

www.trinamic.com

TRINAMIC [ TRINAMIC MOTION CONTROL GMBH & CO. KG. ]

TRINAMIC [ TRINAMIC MOTION CONTROL GMBH & CO. KG. ]