TPS1HC30-Q1

ZHCSP75A –JULY 2022 –REVISED DECEMBER 2022

www.ti.com.cn

9.4 Layout

9.4.1 Layout Guidelines

To prevent thermal shutdown, TJ must be less than 150°C. If the output current is very high, the power

dissipation can be large. The HTSSOP package has good thermal impedance. However, the PCB layout is very

important. Good PCB design can optimize heat transfer, which is absolutely essential for the long-term reliability

of the device.

• Maximize the copper coverage on the PCB to increase the thermal conductivity of the board. The major heat-

flow path from the package to the ambient is through the copper on the PCB. Maximum copper is extremely

important when there are not any heat sinks attached to the PCB on the other side of the board opposite the

package.

• Add as many thermal vias as possible directly under the package ground pad to optimize the thermal

conductivity of the board.

• Plate shut or plug and cap all thermal vias on both sides of the board to prevent solder voids. To ensure

reliability and performance, the solder coverage must be at least 85%.

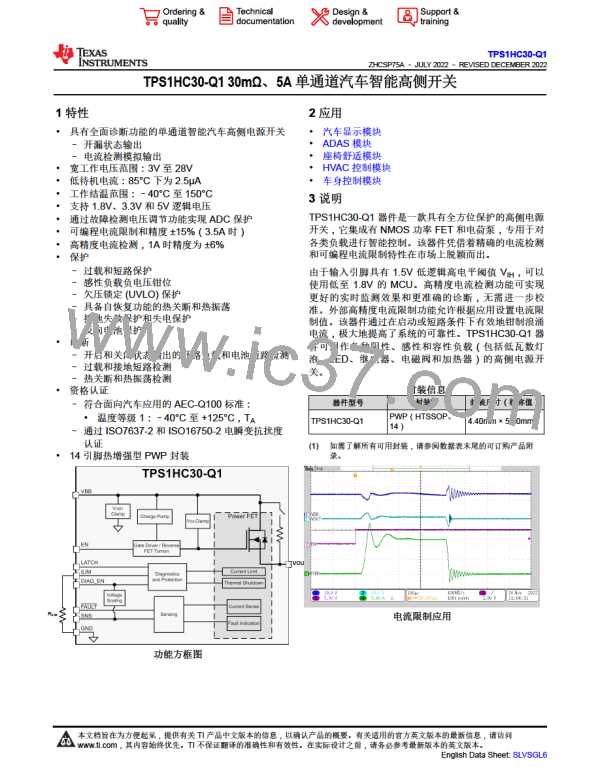

9.4.2 Layout Example

9.4.2.1 Without a GND Network

Without a GND network, tie the thermal pad directly to the board GND copper for better thermal performance.

RPROT

14

CVBB

GND

NC

1

2

3

4

5

6

7

RPROT

13

VBB

VBB

EN

DIAG_EN

FAULT

12

11

RPU

RPROT

Thermal

Pad

NC

RPROT

10

LATCH

SNS

VOUT

VOUT

NC

RPROT

9

8

RSNS

CFILTER

CVOUT

ILIM

RLIM

图9-5. Layout Without a GND Network

Copyright © 2023 Texas Instruments Incorporated

44

Submit Document Feedback

Product Folder Links: TPS1HC30-Q1

TI [ TEXAS INSTRUMENTS ]

TI [ TEXAS INSTRUMENTS ]