www.ti.com

ꢀ ꢁꢂ ꢃꢄ ꢅ

SLOS390A – NOVEMBER 2001– REVISED MAY 2002

and normal operation resumes. During the under-voltage

condition, the outputs are high-impedance to prevent

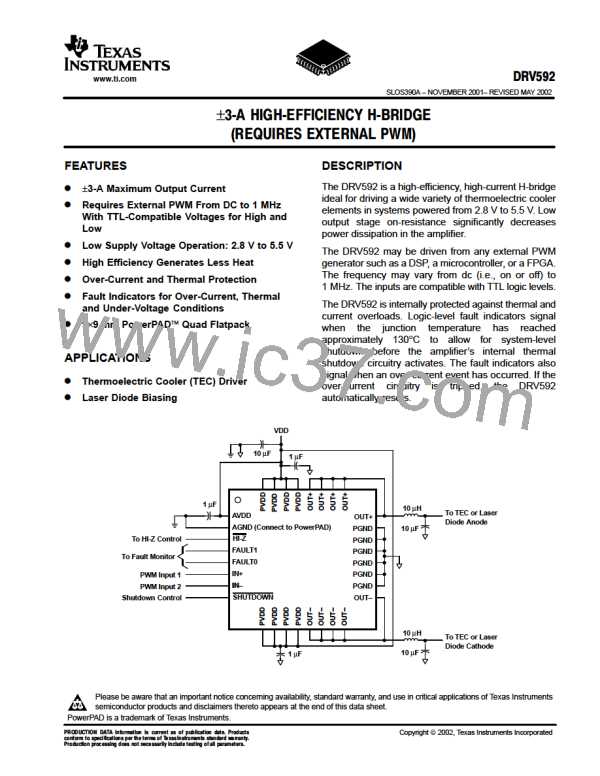

PowerPAD ground connection should be made to

AGND, not PGND. Ground planes are not

recommended for AGND or PGND. Wide traces (100

mils) should be used for PGND while narrow traces

(15 mils) should be used for AGND.

over-dissipation due to increased r

.

DS(on)

The over-temperature fault is reported when the junction

temperature exceeds 130°C. The device continues

operating normally until the junction temperature reaches

190°C, at which point the IC is disabled to prevent

permanent damage from occurring. The system’s

controller must reduce the power demanded from the

DRV592 once the over-temperature flag is set, or else the

device switches off when it reaches 190°C. This flag is not

latched, once the junction temperature drops below

130°C, the fault is cleared, and normal operation resumes.

2. Power supply decoupling. A small 0.1-µF to 1-µF

ceramic capacitor should be placed as close to each

set of PVDD pins as possible, connecting from PVDD

to PGND. A 0.1-µF to 1-µF ceramic capacitor should

also be placed close to the AVDD pin, connecting from

AVDD to AGND. A bulk decoupling capacitor of at

least 10 µF, preferably ceramic, should be placed

close to the DRV592, from PVDD to PGND.

POWER DISSIPATION AND MAXIMUM

AMBIENT TEMPERATURE

3. Power and output traces. The power and output

traces should be sized to handle the desired

maximum output current. The output traces should be

kept as short as possible to reduce EMI, i.e., the

output filter should be placed as close as possible to

the DRV592 outputs.

Though the DRV592 is much more efficient than traditional

linear solutions, the power drop across the on-resistance

of the output transistors does generate some heat in

the package, which may be calculated as shown in

equation (7):

4. PowerPAD.

The DRV592 in the Quad Flatpack

package uses TI’s PowerPAD technology to enhance

the thermal performance. The PowerPAD is

physically connected to the substrate of the DRV592

silicon, which is connected to AGND. The PowerPAD

ground connection should therefore be kept separate

from PGND as described above. The pad underneath

the AGND pin may be connected underneath the

device to the PowerPAD ground connection for ease

of routing. For additional information on PowerPAD

PCB layout, refer to the PowerPAD Thermally

Enhanced Package application note, TI literature

number SLMA002.

+ ǒIOUTǓ2

(7)

P

r

DISS

DS(on), total

For example, at the maximum output current of 3 A through

a total on-resistance of 130 mΩ (at T = 25°C), the power

J

dissipated in the package is 1.17 W.

The maximum ambient temperature may be calculated

using equation (8):

(8)

ǒθ

JA

DISSǓ

T

+ T

*

P

A

J

PRINTED-CIRCUIT BOARD (PCB) LAYOUT

CONSIDERATIONS

5. Thermal performance.

For proper thermal

performance, the PowerPAD must be soldered down

to a thermal land, as described in the PowerPAD

Thermally Enhanced Package application note, TI

literature number SLMA002. In addition, at high

current levels (greater than 2 A) or high ambient

temperatures (greater than 25°C), an internal plane

may be used for heat sinking. The vias under the

PowerPAD should make a solid connection, and the

plane should not be tied to ground except through the

PowerPAD connection, as described above.

Since the DRV592 is a high-current switching device, a

few guidelines for the layout of the printed-circuit board

(PCB) must be considered:

1. Grounding.

Analog ground (AGND) and power

ground (PGND) must be kept separated, ideally back

to where the power supply physically connects to the

PCB, minimally back to the bulk decoupling capacitor

(10 µF ceramic minimum). Furthermore, the

11

TI [ TEXAS INSTRUMENTS ]

TI [ TEXAS INSTRUMENTS ]