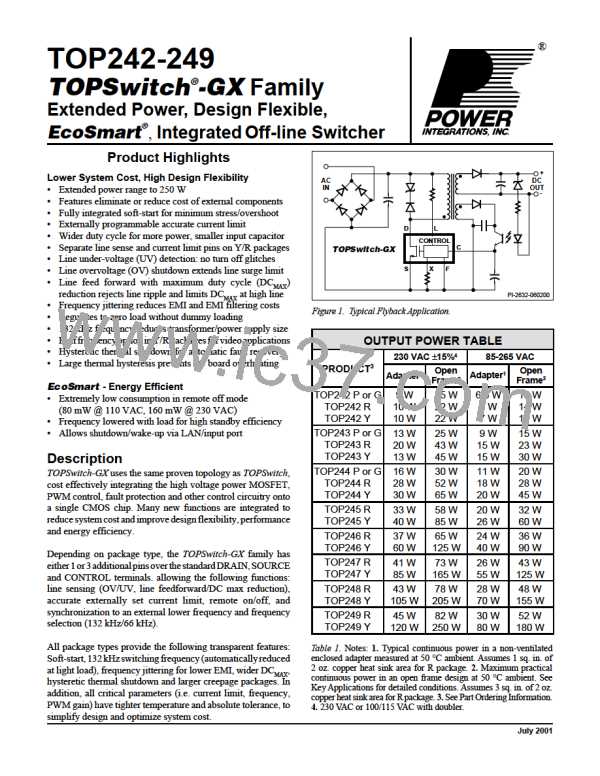

TOP242-249

AHighEfficiency,250W,250–380VDCInputPowerSupply

The circuit shown in figure 43 delivers 250 W (48 V @ 5.2 A)

at 84% efficiency using a TOP249 from a 250 to 380 VDC

input. DCinputisshown, astypicallyatthispowerlevelap.f.c.

boost stage would preceed this supply, providing the DC input

(C1 is included to provide local decoupling). Flyback topology

is still useable at this power level due to the high output voltage,

keeping the secondary peak currents low enough so that the

output diode and capacitors are reasonably sized.

is essential to limit the peak drain voltage during start-up and/

or overload conditions to below the 700 V rating of the

TOPSwitch-GX MOSFET.

The secondary is rectifed and smoothed by D2 and C9, C10 and

C11. Three capacitors are used to meet the secondary ripple

current requirement. Inductor L2 and C12 provide switching

noise filtering.

A simple Zener sensing chain regulates the output voltage. The

sum of the voltage drop of VR2, VR3 and VR4 plus the LED

drop of U2 gives the desired output voltage. Resistor R6 limits

LED current and sets overall control loop DC gain. Diode D4

and C14 provide secondary soft-finish, feeding current into the

CONTROLpinpriortooutputregulationandthusensuringthat

the output voltage reaches regulation at start-up under low line,

full load conditions. Resistor R9 provides a discharge path for

C14. CapacitorC13andR8providecontrolloopcompensation

and are required due to the gain associated with such a high

output voltage.

In this example the TOP249 is at the upper limit of its power

capability and the current limit is set to the internal maximum

by connecting the X pin to SOURCE. However, line sensing is

implemented by connecting a 2 MΩ resistor from the L pin to

the DC rail. If the DC input rail rises above 450 VDC, then

TOPSwitch-GX will stop switching until the voltage returns to

normal, preventing device damage.

Due to the high primary current, a low leakage inductance

transformer is essential. Therefore, a sandwich winding with a

copper foil secondary was used. Even with this technique the

leakage inductance energy is beyond the power capability of a

simple Zener clamp. Therefore, R2, R3 and C6 are added in

parallel to VR1. These have been sized such that during normal

operation very little power is dissipated by VR1, the leakage

energy instead being dissipated by R2 and R3. However, VR1

Sufficient heat sinking is required to keep the TOPSwitch-GX

device below 110 °C when operating under full load, low line

and maximum ambient temperature. Airflow may also be

required if a large heat sink area is not acceptable.

C7

2.2 nF Y1

D2

MUR1640CT

R2

R3

C6

C10

560 µF 560 µF

63 V 63 V

C11

L2

3 µH 8A

VR1

P6KE200

68 kΩ 68 kΩ 4.7 nF

48 V @ 5.2 A

+250 - 380 VDC

2 W

2 W

1 kV

C9

C12

560 µF

68 µF

63 V

63 V

D1

BYV26C

RTN

D2

1N4148

U2

LTV817A

R1

2 MΩ

1/2 W

R9

T1

C4

10 kΩ

1 µF

C1

50 V

22 µF

R6

400 V

100 Ω

TOPSwitch-GX

C13

150 nF

63 V

VR2 22 V

BZX79B22

D

S

L

TOP249Y

U1

D4

PERFORMANCE SUMMARY

1N4148

CONTROL

C

Output Power:

Line Regulation:

Load Regulation:

Efficiency:

250 W

1%

R4

5%

C14

22 µF

63 V

X

F

6.8 Ω

≥ 85%

VR3 12 V

BZX79B12

C3

R8

56 Ω

Ripple:

< 100 mV pk-pk

C3

0.1 µF

No Load Consumption: ≤ 1.4 W (300 VDC)

47 µF

50 V

VR4 12 V

BZX79B12

10 V

0V

All resistor 1/8 W 5% unless

otherwise stated.

PI-2692-033001

Figure 43. 250 W, 48 V Power Supply using TOP249.

E

7/01

August 8, 2000

23

POWERINT [ Power Integrations ]

POWERINT [ Power Integrations ]