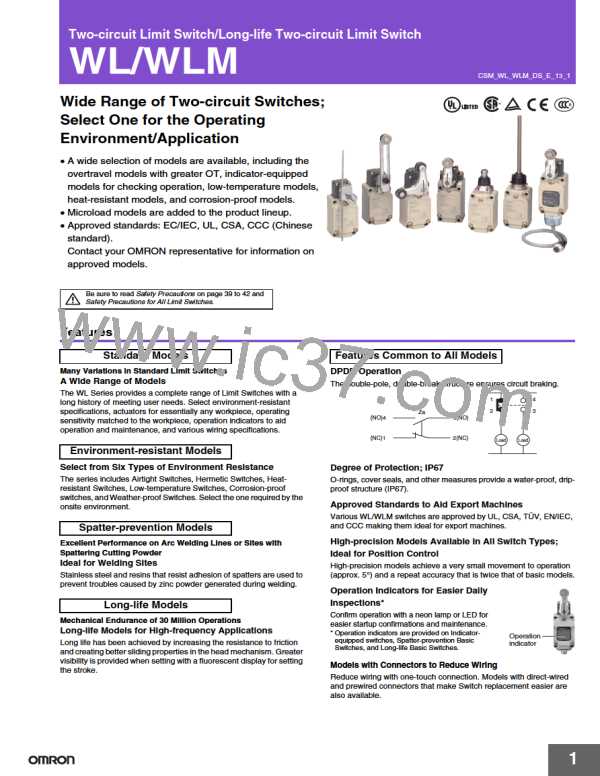

WL/WLM

Built-in Switch

Connectors

Do not remove or replace the built-in switch. If the position of the built-

in switch moves, it can cause reduced performance, and if the

insulation sheet moves (separator), the insulation may become

ineffective.

Either the easy-to-use Allen-head nut or the SC Connector can be

used as connectors. To ensure high-sealing properties, use the SC

Connector. Refer to Limit Switch Connectors for details on SC

Connectors.

Tightening Torque

Wiring

• If screws are too loose they can lead to an early malfunction of the

Switch, so ensure that all screws are tightened using the correct

torque.

• In particular, when changing the direction of the Head, make sure

that all screws are tightened again to the correct torque. Do not

allow foreign objects to fall into the Switch.

• Use 1.25-mm2 lead wires and M4-insulation covered crimp

terminals for wiring.

Crimp Terminal External

Dimensions

Wiring Method

Switch Box Section

L

Ground terminal

F

l

Appropriate

tightening

torque

No.

Type

D dia.

B

1.

6.

Head mounting

screw

3.

1.

2.

0.78 to 0.88 N·m

1.18 to 1.37 N·m

dz dia.: 4.3

D dia. : 4.5

B

L

F

l

dz dia.

Cover mounting

screw

: 8.5

: 21.0

: 7.8

NO terminal

NC terminal

Allen-head bolt

3. (for securing the

lever)

4.

2.

: 9.0 (mm)

4.90 to 5.88 N·m

• The ground terminal is only installed on models with ground

terminals.

4. Terminal screw

5. Connector

0.59 to 0.78 N·m

1.77 to 2.16 N·m

5.

Rotating Lever Set Position (General-purpose or Spatter-

prevention Switches Only)

Installing the Switch

To install the Switch, make a mounting panel, as shown in the

following diagram, and tighten screws using the correct torque.

Mounting

Mounting

All rotating lever models, except the fork lever lock models, have a set

position marker plate. (See page 23.) After operation, set the indicator

needle on the marker plate so that is in the convex section of the

bearing.

Mounting

locations

WL

Operation Set Position (Long-life Switches Only)

For all Long-life Switching, there is a set position marker slit on the

rubber cap of the head. After operation, set the slit on the rubber cap

so that the fluorescent color on the shaft section can be seen.

Front Mountig :Four, 5.2+0.2

dia. holes

0

or M5 tapped holes

Rear Mountig : Four, 6.2+0.2

dia. holes

0

Terminal Plate

Front Mountig/

By using a short circuit plate, as shown in the following diagram, the

Switch can be fabricated into a single-polarity double-break switch.

When ordering, specify WL Terminal Plate (product code: WL-

9662F).

Rear Mountig

58.7 0.15

30.2 0.15

9

2.5+0.2

7.1

0

In case of side mounting for

overtravel,90° WL@-@@2N

Mounting

locations

3R

COM

9

0.2

23 0.4

16 0.15

Two, 5.2 +0.2 dia. holes

0

7

2R

Side Mountig

3.5

2.1R

64 0.15

4.2+0.1

t = 0.6 Brass plate

0

Indicator

Indicator-equipped switch has contacts and indicator in parallel.

When contacts are open, leakage current flows through the indicator

circuit and may cause load's malfunction.

23 0.15

Please check the load's OFF current before use the indicator-

equipped switch.

40

OMRON [ OMRON ELECTRONICS LLC ]

OMRON [ OMRON ELECTRONICS LLC ]