WL/WLM

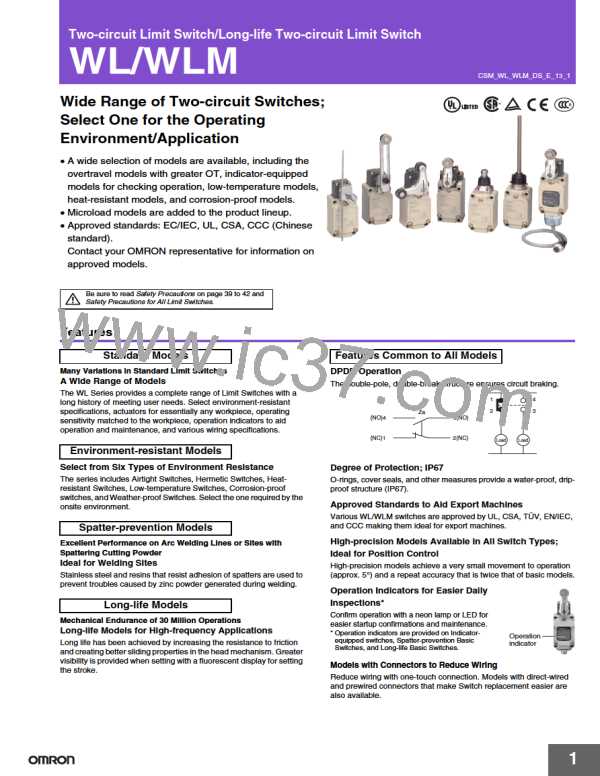

Environment-resistant Switches

Item

Environment-resistant

Type

Model

Application

Environment-resistant construction

Applicable models

All models except the low-

temperature and heat-re-

sistant models

Note: Models can be produced

using standard

Uses the W-10FB3-55 Airtight Built-in Switch.

Note: Use the SC Connector for the conduit opening.

Airtight seal

WL@-55

actuators.

All models except the low-

temperature and heat-re-

sistant models

WL@-139

WL@-140

WL@-141

WL@-145

WL@-RP40

WL@-RP60

For uses in locations sub-

ject to cutting oil or water

Note: Models can be produced

using standard

Hermetic seal

(Molded terminals/

Anti-coolant)

Refer to page 25 for information on the environ-

ment-resistant construction of Switches with Her-

metic Seals.

actuators. Only the

WLCA2, WLGCA2, or

WLH2 can be produced

for the WL@-141 and

WL@-145.

Can be used at a tempera-

ture of –40°C (operating

All models except airtight

seal, hermetic seal, heat-

• Uses a general-purpose built-in switch.

Low-temperature * WL@-TC

temperature range: –40 to • Silicone rubber is used for rubber parts such as resistant, corrosion-proof,

40°C), but cannot with-

stand icing.

the O-ring, gasket, etc.

and indicator-equipped

models

All models except airtight

seal, hermetic seal, heat-

resistant, corrosion-proof,

and indicator-equipped, ny-

lon roller (WLCA2-26N),

seal roller models, and res-

in rod (WLNJ-2) models

Can be used in tempera-

tures of 120°C (operating

temperature range: 5 to

120°C).

• Uses a special built-in switch made from heat-

resistant resin.

• Silicone rubber is used for rubber parts such as

the O-ring, gasket etc.

Heat-resistant *

Corrosion-proof

Weather-proof *

WL@-TH

WL@-RP

WL@-P1

• Diecast parts, such as the switch box, are made

of corrosion-proof aluminum.

• Rubber sealing parts are made of fluorine

rubber which aids in resisting oil, chemicals and

adverse weather conditions.

All models except overtrav-

el (90° operation), fork le-

ver lock (WLCA32-41 to -

43), low-temperature, heat-

resistant, and indicator-

equipped models

For use in locations sub-

ject to corrosive gases and • Exposed nuts and screws (except the actuator

chemicals.

section) are made of stainless steel.

• Moving and rotary parts such as rollers are

made of sintered stainless steel or stainless

steel.

• The Head, box, and cover are yellow.

• Rubber parts are made from silicone rubber,

Only basic (WLCA2/CA12/

which has a high-tolerance to deterioration over CL), general-purpose over-

time and changes in temperature.

• Rollers are made of stainless steel to improve

corrosion resistance.

travel (WLH2/H12/HL) and

high-sensitivity overtravel

(WLG2/G12/GL) models

For use in parking lots and

other outdoor locations.

• Exposed nuts and screws are made of stainless (excluding heat-resistant

steel. models).

* Weather Resistance, Cold Resistance, and Heat Resistance

Silicon rubber is used to increase resistance to weather, cold, and heat. Silicon rubber, however, can generate silicon gas. (This can occur at room temperature, but

the amount of silicon gas generated increases at higher temperatures.) Silicon gas will react as a result of arc energy and form silicon oxide (SiO2). If silicon oxide

accumulates on the contacts, contact interference can occur and can interfere with the device. Before using a Switch, test it under actual application conditions

(including the environment and operating frequency) to confirm that no problems will occur in actual.

4

OMRON [ OMRON ELECTRONICS LLC ]

OMRON [ OMRON ELECTRONICS LLC ]