Application Hints (Continued)

DS101044-10

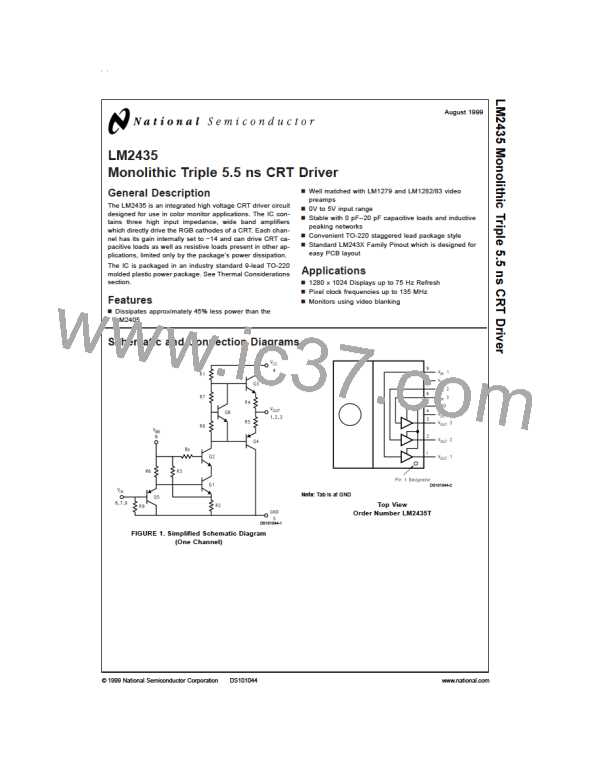

FIGURE 9. One Channel of the LM2435 with the Recommended Application Circuit

OPTIMIZING TRANSIENT RESPONSE

cation. The designer should note that if the load capacitance

is increased the AC component of the total power dissipation

will also increase.

Referring to Figure 9, there are three components (R1, R2

and L1) that can be adjusted to optimize the transient re-

sponse of the application circuit. Increasing the values of R1

and R2 will slow the circuit down while decreasing over-

shoot. Increasing the value of L1 will speed up the circuit as

well as increase overshoot. It is very important to use induc-

tors with very high self-resonant frequencies, preferably

above 300 MHz. Ferrite core inductors from J.W. Miller Mag-

netics (part # 78FR22K) were used for optimizing the perfor-

mance of the device in the NSC application board. The val-

ues shown in Figure 9 can be used as a good starting point

for the evaluation of the LM2435. Using a variable resistor

for R1 will simplify finding the value needed for optimum per-

formance in a given application. Once the optimum values

are determined the variable resistor can be replaced with

fixed values.

The LM2435 case temperature must be maintained below

100˚C. If the maximum expected ambient temperature is

70˚C and the maximum power dissipation is 8.7W (from Fig-

ure 6, 72.5 MHz bandwidth) then a maximum heat sink ther-

mal resistance can be calculated:

This example assumes a capacitive load of 8 pF and no re-

sistive load.

TYPICAL APPLICATION

A typical application of the LM2435 is shown in Figure 10.

Used in conjunction with an LM1279, a complete video chan-

nel from monitor input to CRT cathode can be achieved. Per-

formance is ideal for 1280 x 1024 resolution displays with

pixel clock frequencies up to 135 MHz. Figure 10 is the sche-

matic for the NSC demonstration board that can be used to

evaluate the LM1279/2435 combination in a monitor.

EFFECT OF LOAD CAPACITANCE

Figure 8 shows the effect of increased load capacitance on

the speed of the device. This demonstrates the importance

of knowing the load capacitance in the application.

EFFECT OF OFFSET

PC BOARD LAYOUT CONSIDERATIONS

Figure 7 shows the variation in rise and fall times when the

For optimum performance, an adequate ground plane, isola-

tion between channels, good supply bypassing and minimiz-

ing unwanted feedback are necessary. Also, the length of the

signal traces from the preamplifier to the LM2435 and from

the LM2435 to the CRT cathode should be as short as pos-

sible. The following references are recommended:

output offset of the device is varied from 40 VDC to 50 VDC

.

The rise time shows a maximum variation relative to the cen-

ter data point (45 VDC) of about 13%. The fall time shows a

maximum variation of about 3% relative to the center data

point.

Ott, Henry W., “Noise Reduction Techniques in Electronic

Systems”, John Wiley & Sons, New York, 1976.

THERMAL CONSIDERATIONS

Figure 4 shows the performance of the LM2435 in the test

circuit shown in Figure 2 as a function of case temperature.

The figure shows that the rise time of the LM2435 increases

by approximately 12% as the case temperature increases

from 50˚C to 100˚C. This corresponds to a speed degrada-

tion of 2.4% for every 10˚C rise in case temperature. There

is a negligible change in fall time vs. temperature in the test

circuit.

“Video Amplifier Design for Computer Monitors”, National

Semiconductor Application Note 1013.

Pease, Robert A., “Troubleshooting Analog Circuits”,

Butterworth-Heinemann, 1991.

Because of its high small signal bandwidth, the part may os-

cillate in a monitor if feedback occurs around the video chan-

nel through the chassis wiring. To prevent this, leads to the

video amplifier input circuit should be shielded, and input cir-

cuit wiring should be spaced as far as possible from output

circuit wiring.

Figure

6 shows the maximum power dissipation of the

LM2435 vs Frequency when all three channels of the device

are driving an 8 pF load with a 40 Vp-p alternating one pixel

on, one pixel off signal. The graph assumes a 72% active

time (device operating at the specified frequency) which is

typical in a monitor application. The other 28% of the time

the device is assumed to be sitting at the black level (65V in

this case). This graph gives the designer the information

needed to determine the heat sink requirement for the appli-

It is very important that the tab of the heatsink is connected

to PCB ground. The single ground pin does not provide an

adequate return path at high frequencies. The ground con-

nection can be made using the heatsink. The NSC LM1279

& LM243X (Nov. 1998, Rev. B) demo board, shown in Figure

11 and Figure 12, provides a good example of how this can

be done. A Thermalloy 6698B heatsink is used in the demo

5

www.national.com

NSC [ National Semiconductor ]

NSC [ National Semiconductor ]