Application Hints (Continued)

TACHOMETER APPLICATION

A measure of the operating level of any motor or engine is

the rotational velocity of its output shaft. In the case of an

automotive engine the crankshaft speed is measured using

the units ‘‘revolutions per minute’’ (RPM). It is possible to

indirectly measure the speed of the crankshaft by using the

signal present on the engine’s ignition coil. The fundamental

frequency of this signal is a function of engine speed and

the number of cylinders and is calculated (for a four-stroke

engine) from the formula:

The charge pump circuit in Figure 7 can be operated in two

modes: constant input pulse width (C1 acts as a coupling

capacitor) and constant input duty cycle (C1 acts as a differ-

entiating capacitor). The transfer functions for these two

modes are quite diverse. However, deflection is always di-

rectly proportional to R2 and ripple is proportional to C2.

The following variables are used in the calculation of meter

deflection:

symbol description

e

f

n0/120

(Hz)

(5)

n

number of cylinders

e

e

where n number of cylinders, and 0 rotational velocity of

the crankshaft in RPM. From this formula the maximum fre-

quency normally expected (for an 8 cylinder engine turning

4500RPM) is 300 Hz. In certain specialized ignition systems

(motorcycles and some automobiles) where the coil wave-

e

0, 0

engine speed at redline and idle, RPM

pointer deflection at redline, degrees

charge pump input pulse width, seconds

peak to peak input voltages, volts

maximum desired ripple, degrees

function generator gain, degrees/volt

input frequency at redline and idle, Hz

IDLE

i

e

V

IN

f

form is operated at twice this frequency (

0/60). These

Di

systems are identified by the fact that multiple coils are used

in lieu of a single coil and distributor. Also, the coils have

two outputs instead of one.

k

f

f

IDLE

,

Where the NPN transistor and regulator are used to create a

e

grees (a typical pointer is about 3 degrees wide) depending

on meter damping and the input frequency.

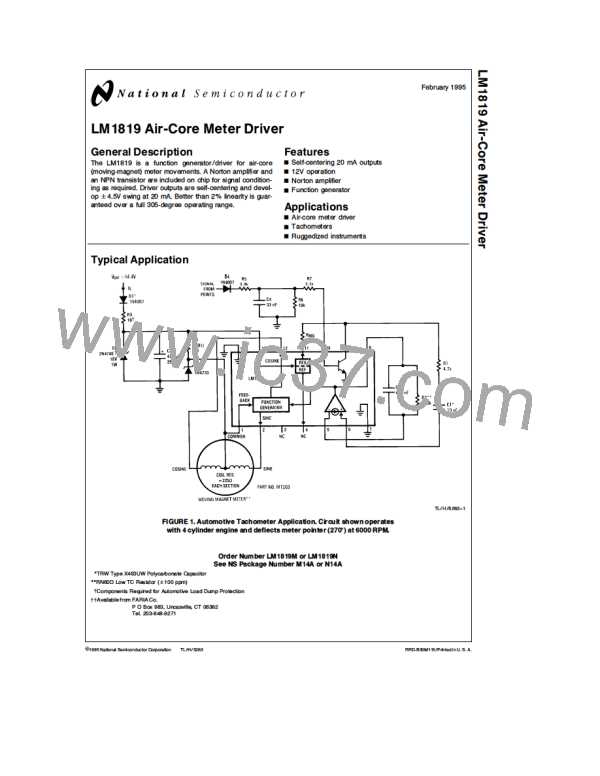

A typical automotive tachometer application is shown inFig-

ure 1. The coil waveform is filtered, squared and limited by

the RC network and NPN transistor. The frequency of the

pulse train at pin 9 is converted to a proportional voltage by

the Norton amplifier’s charge pump configuration. The igni-

tion circuit shown in Figure 5 is typical of automotive sys-

tems. The switching element ‘‘S’’ is opened and closed in

synchronism with engine rotation. When ‘‘S’’ is closed, en-

ergy is stored in Lp. When opened, the current in Lp diverts

from ‘‘S’’ into C. The high voltage produced in Ls when ‘‘S’’

is opened is responsible for the arcing at the spark plug.

The coil voltage (see Figure 6) can be used as an input to

the LM1819 tachometer circuit. This waveform is essentially

constant duty cycle. D4 rectifies this waveform thereby pre-

venting negative voltages from reaching the chip. C4 and

R5 form a low pass filter which attenuates the high frequen-

cy ringing, and R7 limits the input current to about 2.5mA.

R6 acts as a base bleed to shut the transistor OFF when

‘‘S’’ is closed. The collector is pulled up to the internal regu-

pulse V

IN

8.5V. Acceptable ripple ranges from 3 to 10 de-

The constant pulse width circuit is designed using the fol-

lowing equations:

V

IN

k

k

(1)

100 mA

3 mA

R1

10e

t

(2)

C

1

R

1

R i

120R i

1

1

e

e

e

(3)

(4)

R

2

f

V

ek

1

V n0ek

IN

IN

1

e

C

2

f

R Di

2

R Din0

2 IDLE

IDLE

The constant duty cycle equations are as follows:

t

R

R

3 kX

REG

4

x10

s

b

V

IN

R

REG

1

s

a

R )

1

C

1

e/10(R

REG

lator by R

pulse.

. The output at pin 9 is a clean rectangular

REG

e

e

i/425 C

f

R

i/3.54n0C

Z

1

1

e

C

2

425C /Di

1

Many ignition systems use magnetic, hall effect or optical

sensors to trigger a solid state switching element at ‘‘S.’’

These systems (see the LM1815) typically generate pulses

of constant width and amplitude suitable for driving the

charge pump directly.

e

The values in Figure

e

1

270 degrees,

were calculated with

e

n

4,

is

e

0

6000RPM,

i

e 1

ms,

V

IN

b

e

0.7V, and Di 3 degrees in the constant duty cycle

mode. For distributorless ignitions these same equations will

V

REG

f

apply if 0/60 is substituted for

.

4

NSC [ National Semiconductor ]

NSC [ National Semiconductor ]