Absolute Maximum Ratings

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales

Office/Distributors for availability and specifications.

b a

40 C to 85 C

Operating Temperature

§

65 C to 150 C

§

b

b

Storage Temperature

§

§

Lead Temp. (Soldering, 10 seconds)

260 C

§

MIN

Supply Voltage, Va (pin 13)

20V

BV

20V

CEO

Power Dissipation (note 1)

1300 mW

e

e

25 C unless otherwise specified

Electrical Characteristics V

13.1V T

§

S

A

Symbol

Parameter

Supply Current

Pin(s)

Conditions

Min

Typ

Max

65

Units

I

13

Zero Input Frequency

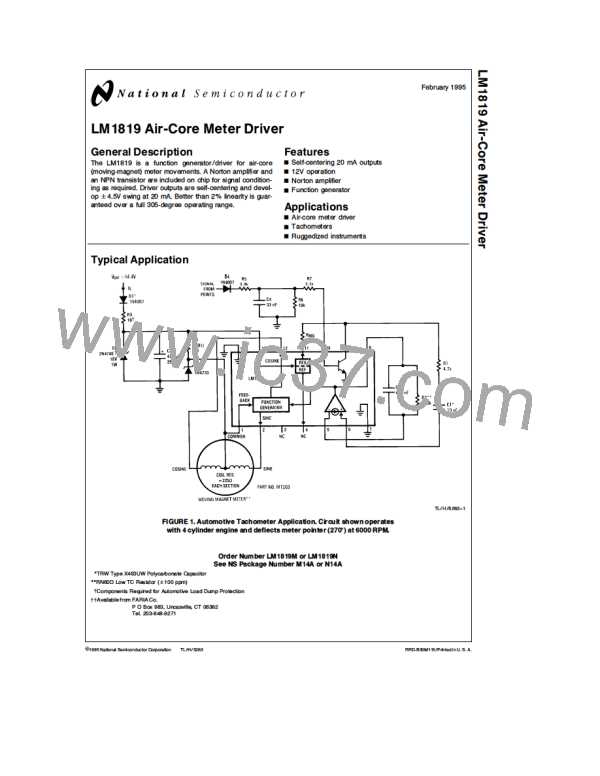

(SeeFigure 1)

S

mA

e

e

e

e

j

V

Regulator Voltage

11

11

4

I

I

I

I

I

0 mA

8.1

1.9

0.9

8.5

13.5

2.1

8.9

V

X

REG

REG

REG

REF

REF

BIAS

Regulator Output Resistance

Reference Voltage

0 mA to 3 mA

0 mA

V

2.3

1.1

V

REF

Reference Output Resistance

Norton Amplifier Mirror Gain

NPN Transistor DC Gain

4

0 mA to 50 mA

20 mA

5.3

kX

5, 6

9, 10

1

1.0

h

125

FE

e

5.1V

Function Generator Feedback

Bias Current

V

1

1.0

mA

V

e

20 mA

Drive Voltage Extremes,

Sine and Cosine

2, 12

2

I

LOAD

g

g

4

4.5

e

V

REF

Sine Output Voltage

with Zero Input

V

8

b

a

350

350

0

mV

e

g

Function Generator Linearity

Function Generator Gain

FSD

305

1.7

%FSD

§

k

Meter Deflection/DV

50.75

53.75

56.75

/V

§

8

Note 1: For operation above 25 C, the LM1819 must be derated based upon a 125 C maximum junction temperature and a thermal resistance of 76 C/W which

§

§

§

applies for the device soldered in a printed circuit board and operating in a still-air ambient.

Application Hints

AIR-CORE METER MOVEMENTS

H fields(Figure 3(c)). H is proportional to the voltage applied

to a coil. Therefore, by varying both the polarity and magni-

tude of the coil voltages the axle assembly can be made to

Air-core meters are often favored over other movements as

a result of their mechanical ruggedness and their indepen-

dence of calibration with age. A simplified diagram of an air-

core meter is shown in Figure 2. There are three basic

pieces: a magnet and pointer attached to a freely rotating

axle, and two coils, each oriented at a right angle with re-

spect to the other. The only moving part in this meter is the

axle assembly. The magnet will tend to align itself with the

vector sum of H fields of each coil, where H is the magnetic

rotate a full 360 . The LM1819 is designed to drive the me-

§

ter through a minimum of 305 .

§

field strength vector. If, for instance,

a current passes

through the cosine coil (the reason for this nomenclature

will become apparent later) as shown in Figure 3(a), the

magnet will align its magnetic axis with the coil’s H field.

Similarly, a current in the sine coil (Figure 3(b)) causes the

magnet to align itself with the sine H field. If currents are

applied simultaneously to both sine and cosine coils, the

magnet will turn to the direction of the vector sum of the two

TL/H/5263–2

FIGURE 2. Simplified Diagram of an Air Core Meter.

2

NSC [ National Semiconductor ]

NSC [ National Semiconductor ]