MPQ4559 – 1.5A, 2MHz, 55V STEP-DOWN CONVERTER AEC-Q100 QUALIFIED

With higher switching frequencies, the inductive

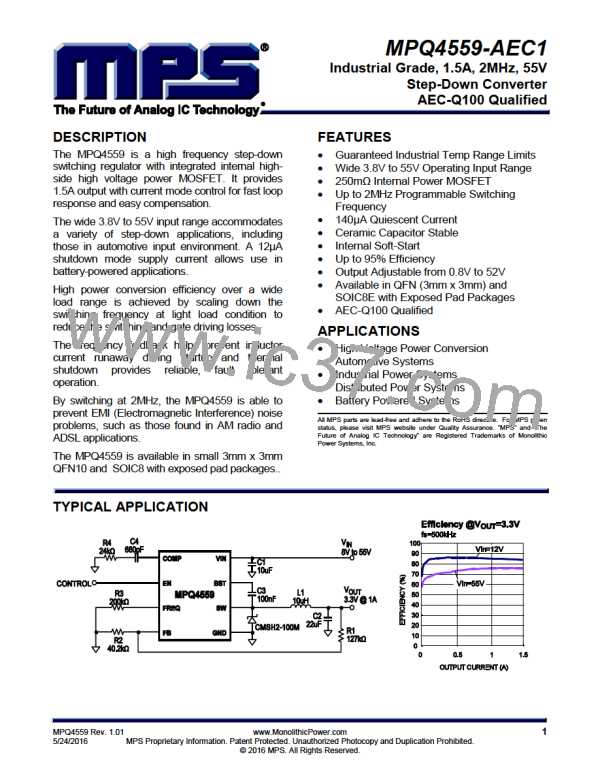

External Bootstrap Diode

reactance (XL) of capacitor comes to dominate,

so that the ESL of input/output capacitor

determines the input/output ripple voltage at

higher switching frequency. As a result of that,

high frequency ceramic capacitor is strongly

recommended as input decoupling capacitor and

output filtering capacitor for such high frequency

operation.

An external bootstrap diode may enhance the

efficiency of the regulator. In below cases, an

external BST diode is recommended from the 5V

to BST pin:

There is a 5V rail available in the system;

VIN is no greater than 5V;

VOUT is between 3.3V and 5V;

Layout becomes more important when the device

switches at higher frequency. It is essential to

place the input decoupling capacitor, catch diode

and the MPQ4559 (VIN pin, SW pin and PGND)

as close as possible, with traces that are very

short and fairly wide. This can help to greatly

reduce the voltage spike on SW node, and lower

the EMI noise level as well.

This diode is also recommended for high duty

cycle operation (when VOUT/VIN

applications.

>

65%)

The bootstrap diode can be a low cost one such

as IN4148 or BAT54.

Try to run the feedback trace as far from the

inductor and noisy power traces as possible. It is

often a good idea to run the feedback trace on

the side of the PCB opposite of the inductor with

a ground plane separating the two. The

compensation components should be placed

closed to the MPQ4559. Do not place the

compensation components close to or under high

dv/dt SW node, or inside the high di/dt power

loop. If you have to do so, the proper ground

plane must be in place to isolate those. Switching

loss is expected to be increased at high switching

frequency. To help to improve the thermal

conduction, a grid of thermal vias can be created

right under the exposed pad. It is recommended

that they be small (15mil barrel diameter) so that

the hole is essentially filled up during the plating

process, thus aiding conduction to the other side.

Too large a hole can cause ‘solder wicking’

problems during the reflow soldering process.

The pitch (distance between the centers) of

several such thermal vias in an area is typically

40mil.

Figure 2—External Bootstrap Diode

At no load or light load, the converter may

operate in pulse skipping mode in order to

maintain the output voltage in regulation. Thus

there is less time to refresh the BS voltage. In

order to have enough gate voltage under such

operating conditions, the difference of (VIN –VOUT

should be greater than 3V. For example, if the

VOUT is set to 3.3V, the VIN needs to be higher

than 3.3V+3V=6.3V to maintain enough BST

voltage at no load or light load. To meet this

requirement, EN pin can be used to program the

input UVLO voltage to VOUT+3V.

MPQ4559 Rev. 1.01

5/24/2016

www.MonolithicPower.com

MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2016 MPS. All Rights Reserved.

15

MPS [ MONOLITHIC POWER SYSTEMS ]

MPS [ MONOLITHIC POWER SYSTEMS ]