Reflector Design

Reflector cavities serve two main purposes: to

redirect the light from the LED into a useful

beam pattern, and to provide a unique

appearance for the finished lamp. Often the look

sought after is not achievable by the most

optically efficient design. As a result, there is a

trade-off required between optical efficiency

and lit appearance to arrive at an acceptable

design.

the reflector. Once the parabola has been

designed, a cavity with a profile comprised of

multiple linear sections that closely approximates

the form of the parabola may be used depending

on the look desired.

In order to accommodate the SuperFlux LED

dome, the bottom aperture of the reflector must

be greater than three-millimeters in diameter.

Considering the tolerances of the molded

As discussed in the previous section Point

Source Optical Model, a parabola is designed

to collimate the light from the point source. For

reflector, the LED, the LED alignment to the PCB,

and the alignment of the reflector to the PCB, the

bottom reflector aperture should be a minimum of

the design technique discussed here, the LED is 3.5 mm in diameter. The focal length of the

treated as a point source. This treatment is very

accurate for larger parabolas where the size of

the dome is small relative to the exit aperture of

reflector must be greater than 0.5 mm to produce

a bottom aperture of greater than 3.5 mm.

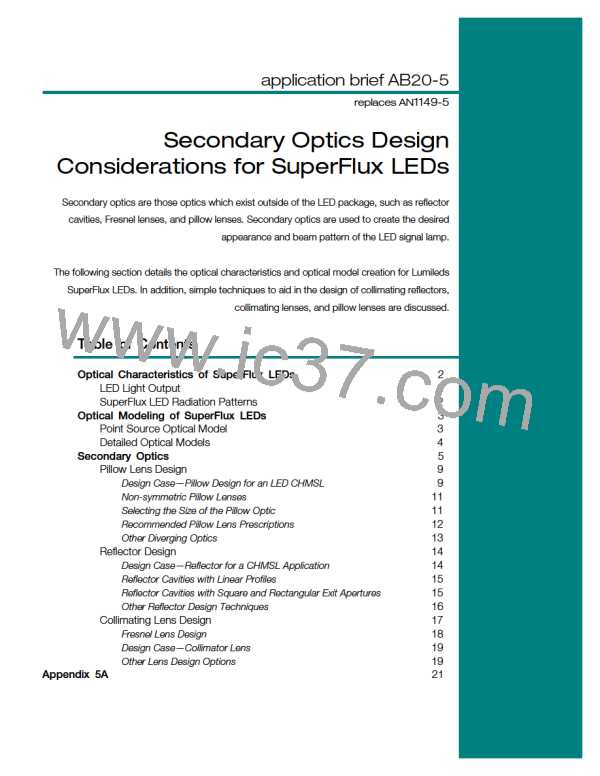

Design Case—Reflector for a CHMSL Application

Consider the case where a reflector cavity will be used to

collimate the light from an HPWT-MH00 source, and a

pillow optic cover lens will be used to form the final radiation

pattern. Vacuum-metalized ABS plastic will be used as the

reflector material. The reflector cavity can be a maximum of

20 mm in height and should have a minimum opening for

the LED dome of diameter 3.75mm to accommodate piece-

part misalignment and tolerances. The LED spacing is 15

mm, and each cell must illuminate a 15 mm x 15 mm patch

on the pillow lens. Figure 5.21 shows a cross-section of the

lamp described above. The geometry of a parabola, in polar

coordinates, is described by the following equation:

Table 5.4 describes the profiles of three different parabolas

(f = 0.9 mm, 0.7 mm, 0.66 mm).

An efficient, practical collimator design for a CHMSL

application should collimate all the light beyond 20°?from on

axis (f £ 20°). More efficient reflectors can be designed which

collimate more of the light, but they are typically too deep to be

of practical value.

The ideal reflector for this application will have the following

characteristics:

Height constraint: 0.99 £ z £ 20 mm

Fit of LED dome into bottom aperture:x (z = 0.99 mm) ³ ?1.875

mm

Figure 5.22 shows how the terms in this equation are

applied.

15 mm pitch: x (F = 20°) @?7.5 mm

From Table 5.1, we find that the optimum point source

location for the HPWT-MH00 LED is at Z = 0.99 mm.

Placing the point source of the LED at the focus of the

parabola will result in an LED position as shown in Figure

5.23.

Looking at Table 5.4, we find that the parabola with f = 0.66

mm most closely meets these requirements. Figure 5.24 gives

the geometry of the parabolic reflector chosen.

Since the base of the LED dome is above the location of the

parabola’s focus, this implies that 2f < 1/2 base aperture =

3.75 mm/2 = 1.875 mm (f < 0.94 mm). This information will

give us a starting point to begin searching for the optimum

parabola.

14

LUMILEDS [ LUMILEDS LIGHTING COMPANY ]

LUMILEDS [ LUMILEDS LIGHTING COMPANY ]