LT3840

applicaTions inForMaTion

the bulk capacitance and RMS current capability. The bulk

capacitance will determine the supply input ripple voltage.

The RMS current capability is used to prevent overheating

the capacitor. The bulk capacitance is calculated based on

requirements. ΔV

is a function of ΔI and the C

OUT L OUT

ESR. It is calculated by:

1

∆VOUT =∆I • ESR+

L

maximum input ripple, ΔV :

8•f •C

(

)

IN

SW OUT

IOUT(MAX) •VOUT

The maximum ESR required to meet a ΔV

requirement can be calculated by:

design

CIN(BULK)

=

OUT

ΔVIN •fSW •VIN(MIN)

∆V

L f

SW

VOUT

VIN(MAX)

(

)

(

)

(

)

OUT

ΔV is typically chosen at a level acceptable to the user.

IN

ESR(MAX)=

A good starting point is 100mV to 200mV. Aluminum

electrolytic capacitors are a good choice for high voltage,

bulkcapacitanceduetotheirhighcapacitanceperunitarea.

VOUT • 1–

Worst-caseΔV

occursatthehighestinputvoltage.Use

OUT

The capacitor’s RMS current is:

paralleled multiple capacitors to meet the ESR require-

ments. Increasing the inductance is an option to lower the

VOUT(V – V

)

IN

OUT

ICIN(RMS) =IOUT

(V )2

OUT

ESRrequirements.ForextremelylowΔV ,anadditional

IN

LC filter stage can be added to the output of the supply.

Linear Technology’s Application Note 44 has some good

tips on sizing an additional output filter.

If applicable, calculate it at the worst-case condition,

= 2V . The RMS current rating of the capacitor

V

IN

OUT

is specified by the manufacturer and should exceed the

calculated I . Due to their low ESR (equivalent

Output Voltage Programming

CIN(RMS)

A resistive divider sets the DC output voltage according

to the following formula:

series resistance), ceramic capacitors are a good choice

for high voltage, high RMS current handling. Note that the

ripplecurrentratingsfromaluminumelectrolyticcapacitor

manufacturersarebasedon2000hoursoflife.Thismakes

it advisable to further derate the capacitor or to choose

a capacitor rated at a higher temperature than required.

VOUT

1.250V

R2=R1

–1

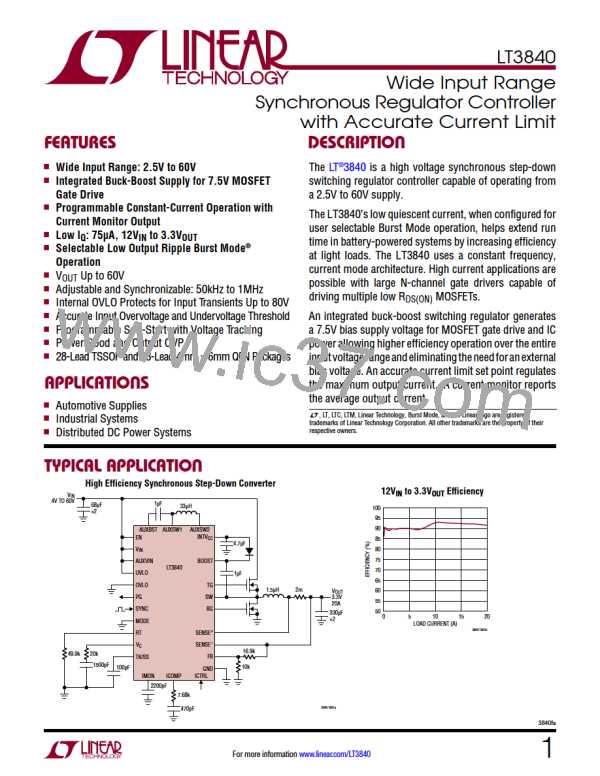

The external resistor divider is connected to the output of

the converter as shown in Figure 6.

The combination of aluminum electrolytic capacitors and

ceramic capacitors is an economical approach to meeting

the input capacitor requirements. The capacitor voltage

L1

V

OUT

rating must be rated greater than maximum V voltage.

IN

R2

R1

C

OUT

Multiple capacitors may also be paralleled to meet size

or height requirements in the design. Locate the capaci-

tor very close to the MOSFET switch and use short, wide

PCB traces to minimize parasitic inductance. Use a small

FB

3840 F06

Figure 6. Output Voltage Feedback Divider

(0.1μF to 1μF) bypass capacitor between the chip V pin

IN

and GND, placed close to the LT3840.

Tolerance of the feedback resistors will add additional er-

Output Capacitor Selection

ror to the output voltage. The V pin input bias current

FB

The output capacitance, C , selection is based on the

is typically 5nA, so use of extremely high value feedback

OUT

design’s output voltage ripple, ΔV

and transient load

resistors results in a converter output that is slightly

OUT

3840fa

16

For more information www.linear.com/LT3840

Linear [ Linear ]

Linear [ Linear ]