PRELIMINARY DATASHEET

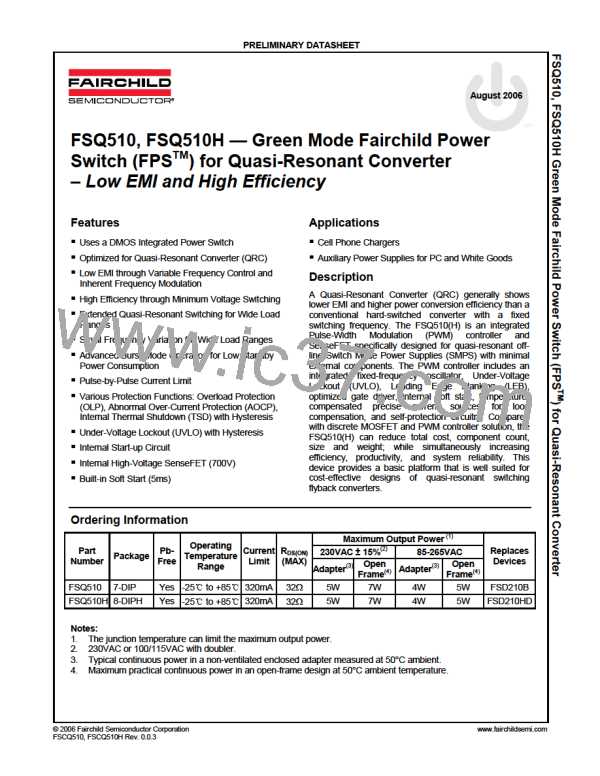

2. Transformer Construction

Core: EE1616 (PM7/ Ae=20.5mm2)

Bobbin: Horizontal 8 pins, 4 pins at each side, 10mm width (bobbin wall-to-wall)

1

8

2mm

2mm

Top

Np

Ns

Tape 4T

Ncc

Ns

Tape 2T

4

7

3

2

3

7

Tape 2T

Tape 1T

Shield

8

4

Np

1

2

Tape 4T

Ncc

Shield

1

Bottom

4

Figure 14. Transformer Construction Illustration

3. Winding Specifications

Pin (S → F)

Wire

Turns

Winding Method

Shield

Np

1 → X

0.16φ×1

48 Ts

Solenoid winding

Insulation: Polyester Tape t = 0.025mm, 4 Layers

2 → 1

0.16φ×1 92 Ts

Insulation: Polyester Tape t = 0.025mm, 1 Layer

4 → X Copper 8mm× 0.05t 0.9 Ts

Insulation: Polyester Tape t = 0.025mm, 2 Layers

8 → 6

0.55φ×1 5 Ts

Insulation: Polyester Tape t = 0.025mm, 2 Layers

Solenoid winding

Copper Plate

Shield

Ns

Solenoid winding

Barrier Tape 2mm

Center Solenoid winding

Barrier Tape 2mm

Ncc

3 → 4

0.16φ×2

11 Ts

Insulation: Polyester Tape t = 0.025mm, 4 Layers

4. Electrical Characteristics

Pin

Specification

1.2mH ± 10%

Remark

100kHz, 1V

Short 2nd pins

Inductance

Leakage

1-2

1-2

60µH maximum

© 2006 Fairchild Semiconductor Corporation

FSQ510, FSQ510H Rev. 0.0.3

www.fairchildsemi.com

12

FAIRCHILD [ FAIRCHILD SEMICONDUCTOR ]

FAIRCHILD [ FAIRCHILD SEMICONDUCTOR ]