PAD

FUNCTION

PAD

FUNCTION

10*

11

12

13

14

15

16

17

18

Common

Output

+VCC

Filter

–In

1

2

3

4

5

6

7

8

9

Offset Adjust

X10 Gain

X100 Gain

X1000 Gain

X1000 Gain Sense

Gain Sense

Gain Set

+In

Offset Adjust

(A1 Output)

(A2 Output)

CMR Trim

–VCC

* Glass covers upper one-third of this pad.

Substrate Bias: Electrically connected to –V supply.

NC: No Connection.

MECHANICAL INFORMATION

MILS (0.001")

MILLIMETERS

Die Size

Die Thickness

Min. Pad Size

142 x 104 ±5

20 ±3

3.61 x 2.64 ±0.13

0.51 ±0.08

0.10 x 0.10

4 x 4

Backing

Gold

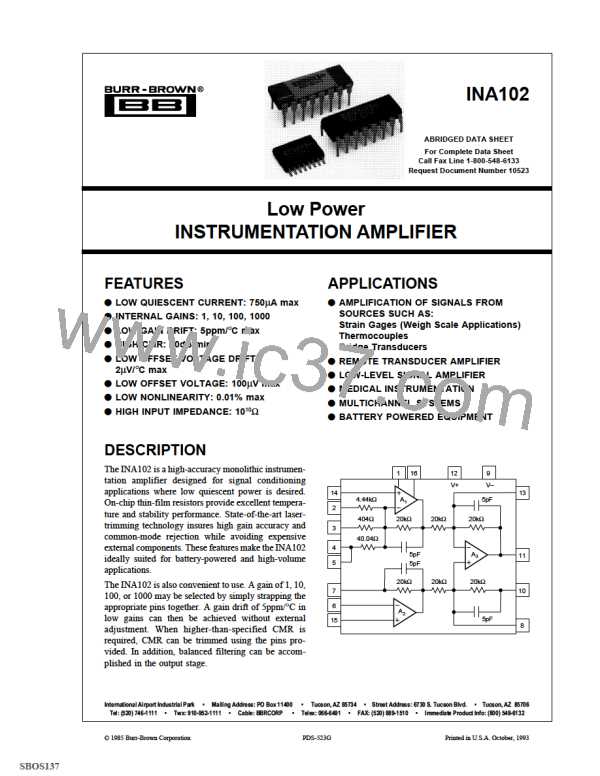

INA102 DIE TOPOGRAPHY

TYPICAL PERFORMANCE CURVES

At +25°C and in circuit of Figure 2 unless otherwise noted.

GAIN vs FREQUENCY

COMMON-MODE REJECTION vs SOURCE IMBALANCE

120

80

VOUT = 0.1Vrms

G = 1000

60

40

20

0

G = 10 to 1000

100

G = 100

G = 10

G = 1

G = 1

80

RIMB

60

1% Error

20Vp-p

5Hz

10kΩ

40

–20

100

1k

10k

100k

1M

10

100

1k

10k

100k

1M

Frequency (Hz)

Source Resistance Imbalance (Ω)

COMMON-MODE REJECTION vs FREQUENCY

WARM-UP DRIFT vs TIME

120

100

80

50

40

30

20

10

0

G = 100

G = 1000

G = 10

G = 1

60

VIN = 20Vp-p

0Ω Source Imbalance

40

0

1

2

3

4

5

1

10

100

1k

Frequency (Hz)

Time (ms)

®

BB [ BURR-BROWN CORPORATION ]

BB [ BURR-BROWN CORPORATION ]