ADT7310

PCB design for optimized thermal performance

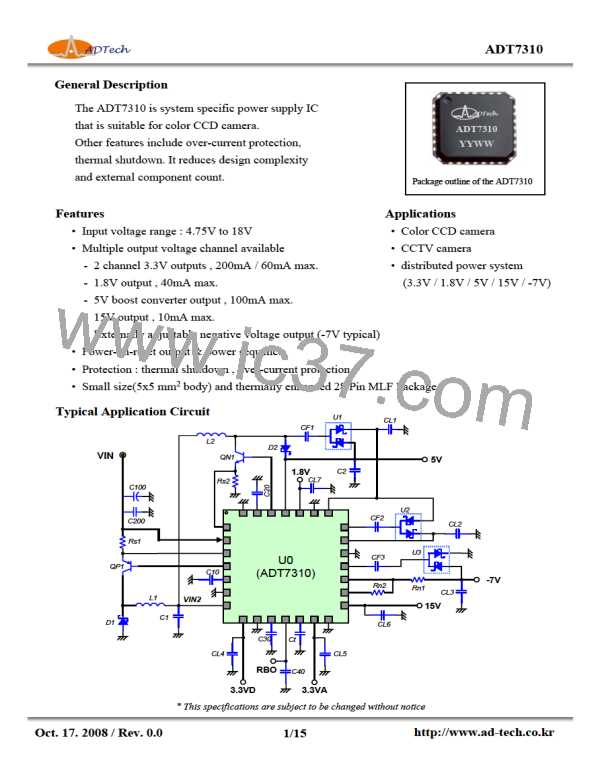

<Figure 4. PCB land pattern – Bottom Layer>

4. Stencil MASK

In order to effectively remove the heat from the package and to

enhance electrical performance the exposed PAD needs to be

soldered to the thermal PAD, preferably with minimum voids.

If the solder paste coverage is too big, out gassing occurs

during reflow process which may cause defects (splatter,

solder balling). Therefore, It is recommended that smaller

multiple openings in stencil should be used instead of one big

opening for printing solder paste on the thermal PAD region

(Figure 5). This will typically result in 50 to 80% solder paste

coverage

1.0mm dia. Circles

@1.2mm Pitch

<Figure 5. Thermal PAD stencil MASK>

5. Reflow condition

Reflow profile and peak temperature has a strong influence on

void formation. Voids in the thermal PAD region reduce as the

peak reflow temperature is 250~270℃. Solder extrusion from

the bottom side of the PCB reduces as the reflow temperature

is reduced.

Reference :

1. B.Guenin, “Packaging: Designing for Thermal Performance.” Electronics Cooling, May1997.

2. Application Note: “Application Notes for Surface Mount Assembly of Amkor’s Micro Lead Frame

( MLF) Packages.” Amkor Technology, March2001

* This specifications are subject to be changed without notice

http://www.ad-tech.co.kr

Oct. 17. 2008 / Rev. 0.0

14/15

ADTECH [ ADTECH ]

ADTECH [ ADTECH ]