Application Information: continued

choose any output voltage by using resistor divider feed-

A change in line voltage changes the current ramp in the

TM

inductor, affecting the ramp signal, which causes the V2

control scheme to compensate the duty cycle. Since the

back to the VFB pin, as in traditional controllers. The

CS51312 is specifically designed to meet or exceed Intel’s

Pentium® II specifications.

change in inductor current modifies the ramp signal, as in

current mode control, the V2TM control scheme has the same

advantages in line transient response.

Error Amplifier

A change in load current will have an affect on the output

voltage, altering the ramp signal. A load step immediately

changes the state of the comparator output, which controls

the main switch. Load transient response is determined

only by the comparator response time and the transition

speed of the main switch. The reaction time to an output

load step has no relation to the crossover frequency of the

error signal loop, as in traditional control methods.

The error signal loop can have a low crossover frequency,

since transient response is handled by the ramp signal loop.

The main purpose of this ‘slow’ feedback loop is to provide

DC accuracy. Noise immunity is significantly improved,

since the error amplifier bandwidth can be rolled off at a

low frequency. Enhanced noise immunity improves remote

sensing of the output voltage, since the noise associated

with long feedback traces can be effectively filtered.

Line and load regulation are drastically improved because

there are two independent voltage loops. A voltage mode

controller relies on a change in the error signal to compen-

sate for a deviation in either line or load voltage. This

change in the error signal causes the output voltage to

change corresponding to the gain of the error amplifier,

which is normally specified as line and load regulation.

The COMP pin is the output of the error amplifier. A

capacitor to Gnd compensates the error amplifier loop.

Additionally, the built in offset on the PWM Comparator

non-inverting input provides the hiccup timing for the

Over-Current Protection, Soft Start function, and regulator

output enable.

VCC2 Charge Pump

In order to fully turn on the high side NFET, a voltage

greater than the input voltage must be applied to VCC2 to

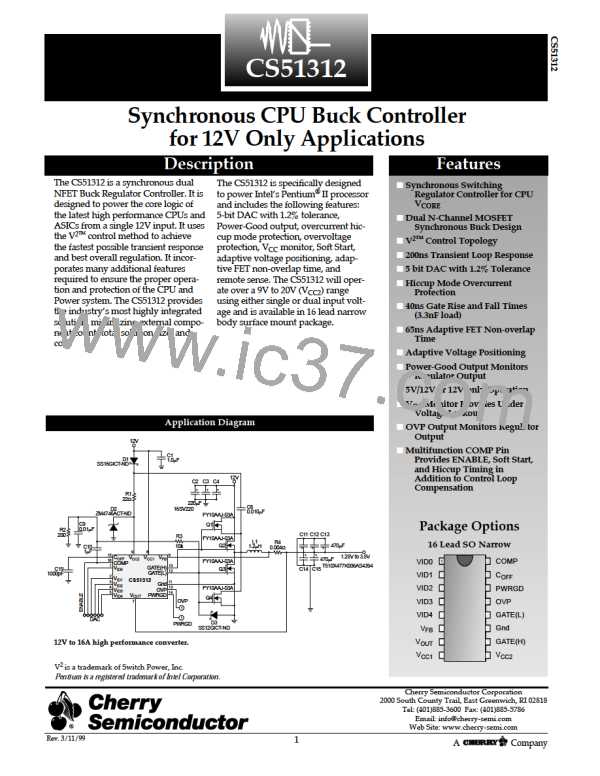

bias the GATE(H) driver. Referring to the application dia-

gram on page 1; a simple charge pump circuit can be

implemented for this purpose through capacitor C6, resis-

tor R1, and diodes D1 and D2. The input voltage, less the

drop in D1 is stored in C6 during the off-time period.

When the high-side FET turns on, it drives the inductor

switching node and C6 high causing schottky diode D1 to

reverse bias. The charge stored in C6 is transferred to VCC2

through R1. Zener diode D2 clamps the VCC2 voltage to

18V to prevent the VCC2 from exceeding its 20V Max rating

(see Figure 7).

A current mode controller maintains fixed error signal

under deviation in the line voltage, since the slope of the

ramp signal changes, but still relies on a change in the error

signal for a deviation in load. The V2TM method of control

maintains a fixed error signal for both line and load varia-

tion, since the ramp signal is affected by both line and load.

Constant Off-Time

To minimize transient response, the CS51312 uses a

Constant Off-Time method to control the rate of output

pulses. During normal operation, the Off-Time of the high

side switch is terminated after a fixed period, set by the

COFF capacitor. Every time the VFB pin exceeds the COMP

pin voltage an Off-Time is initiated. To maintain regula-

tion, the V2TM Control Loop varies switch On-Time. The

PWM comparator monitors the output voltage ramp, and

terminates the switch On-Time.

Constant Off-Time provides a number of advantages.

Switch duty Cycle can be adjusted from 0 to 100% on a

pulse-by pulse basis when responding to transient condi-

tions. Both 0% and 100% Duty Cycle operation can be

maintained for extended periods of time in response to

Load or Line transients.

Figure 7: VCC2 Charge Pump Operation (1µs/div).

Channel 1 - Charge Pump Switching Node (10V/div)

Channel 2 - VCC2 (10V/div)

Channel 3 - GATE(H) (10V/div)

Channel 4 - Inductor Switching Node (10V/div)

Startup

The CS51312 provides a controlled startup of regulator out-

put voltage and features Programmable Soft Start imple-

mented through the Error Amp and external Compensation

Capacitor. This feature, combined with overcurrent protec-

tion, prevents stress to the regulator power components

and overshoot of the output voltage during startup.

Programmable Output

The CS51312 is designed to provide two methods for pro-

gramming the output voltage of the power supply. A five

bit on board digital to analog converter (DAC) is used to

program the output voltage within two different ranges.

The first range is 2.125V to 3.525V in 100mV steps, the sec-

ond is 1.325V to 2.075V in 50mV steps, depending on the

digital input code. If all five bits are left open, the CS51312

enters adjust mode. In adjust mode, the designer can

As Power is applied to the regulator, the CS51312

Undervoltage Lockout circuit (UVL) monitors the ICs sup-

ply voltage (VCC1) which is typically connected to the +12V

input. The UVL circuit prevents the NFET gates from being

activated until VCC1 exceeds the 8.4V (typ) threshold.

7

CHERRY [ CHERRY SEMICONDUCTOR CORPORATION ]

CHERRY [ CHERRY SEMICONDUCTOR CORPORATION ]