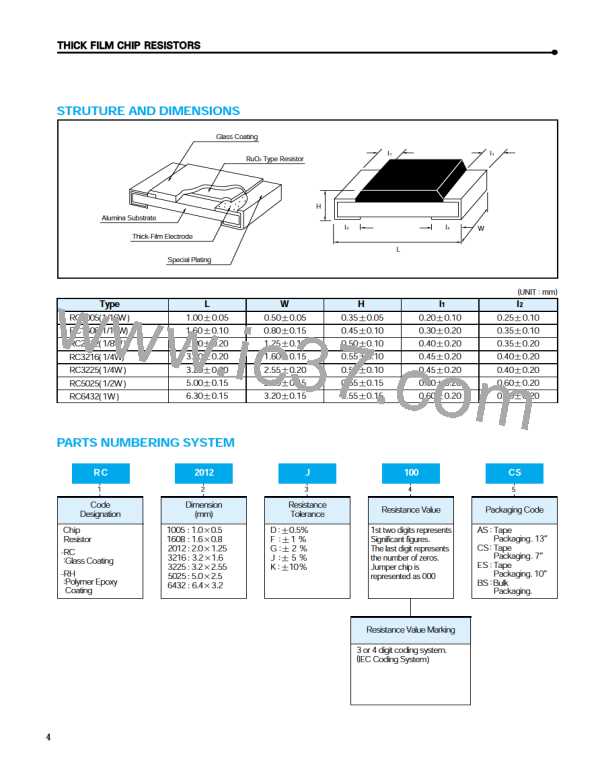

THICK FILM CHIP RESISTORS

CHARACTERISTICS PERFORMANCE

ELECTRICAL CHARACTERISTICS

Item

Specification

Test Method

Within the regulated resistance tolerance.

Applying time:within 5 sec

Resistance range(Ω)

100

Direct Current

Resistance

Jumper chip ꢃ50

㏁

Max test voltage(V)

R

0.3

1.0

3

10

25

50

100ꢃR 1K

1KꢃR 10K

10KꢃR 100K

100KꢃR 1M

1MꢃR

→

→

→

→

T.C.R(Resistance

Temperature

Characteristic)

1ꢃR 10:+300ppm/℃

-200ppm/℃

10ꢃR 1M:±100ppm/℃

1MꢃRꢃ10M:±300ppm/℃

Test temperature(℃) (20) (-55) (20) (125) (20)

T.C.R(ppm/℃) = (R-Ro)/Ro×1/(T-To) ×106

T = 20(℃)

T = Test temperature(℃)

Ro = Resistance at room temperature(Ω)

R = Resistance at T(Ω)

△

Apply 2.5 times rated voltage for 5sec.

Wait 30 minutes at room temperature and measure the

resistance value.

R : ꢃ±(1%+0.1Ω) of the initial value

Short-time Overload

Visual : No evidence of mechanical damage

Jumper chip : ꢃ50

㏁

△

Perform 10,000 cycles at 2.5 times RCW or the Max.

over load voltage

ON(2.5 times rated volage) : 1 sec

Intermittent

Overload

R : ꢃ±(3%+0.1Ω) of the initial value

Visual : No evidence of mechanical damage

Jumper chip : ꢃ50

㏁

OFF

: 25 sec

Have stabilization time of 30 minutes without loading

and measure resistance.

No evidence of mechanical damage.

Over the 1000

Apply AC 500V for 1 minute.

1005(1/16W), 1608(1/16W):Apply AC 100V for 1 minute

Dielectric withstand-

ing Voltage

Insulation Resistance

Apply DC 500V for 1 minute.

1005(1/16W), 1608(1/16W):Apply DC 100V for 1 minute

㏁

MECHANICAL CHARACTERISTICS

Item

Specification

Test Method

Solderability

Coverage : ꢂ95% each termination.

Visual : No crack of termination parts and

ceramic exposure of surface by melting

After immersing in flux. dip into the 235±5℃ molten

solder for 2±0.5 sec

Solder : S63A(KSD 6704)

Flux : ROSIN(KSM 2951)

Flux is the composition of ROSIN and the methanol Weight

rate of ROSIN is about 25%

△

After soldering resistor on the

PCB, 3mm of bending shall

be applied for 10 sec.

Bending Test

R : ꢃ±(0.5%+0.05Ω) of the initial value

Visual : No evidence of mechanical damage.

Material of PCB : Glass Epoxy

Thickness : 1.6mm

Measure resistance during load application

pull Direction fixed 0.4 lead

Terminal Strenght

Terminal Strenght

Load pull : ꢂ0.5kg

1005(1/16W), 1608(1/16W)ꢂ0.3kg

△

R : ꢃ±(1%+0.05Ω) of the initial value

Immerse in molten solder at 260±5℃for 10±1 sec.

Preheat and soldering Procedure

Visual : No evidence of mechanical damage.

Time(sec)

Temperature(℃)

Solder : S63A(SSD 6704)

Flux : The composition of ROSIN

(KSM295)25% and methanol

(KSM 1658)75%

80 - 100

150 - 180

260 + 5

150 - 180

80 - 100

120

120

10

60

60

△

2 hours each in X, Y, and Z axis(toyal 6 hours) 10 to

55 Hz sweep in 1 minute ampiltude.

Anti-Vibration Test

R : ꢃ±(1%+0.05Ω) of the initial value

Visual : No evidence of mechanical damage.

12

ETC [ ETC ]

ETC [ ETC ]