TMC5130A DATASHEET (Rev. 1.14 / 2017-MAY-15)

92

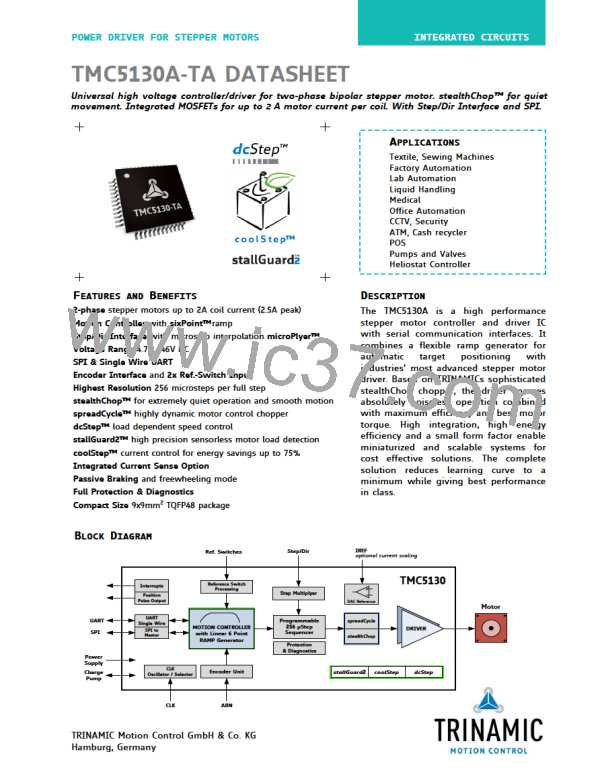

19 dcStep

dcStep is an automatic commutation mode for the stepper motor. It allows the stepper to run with

its target velocity as commanded by the ramp generator as long as it can cope with the load. In case

the motor becomes overloaded, it slows down to a velocity, where the motor can still drive the load.

This way, the stepper motor never stalls and can drive heavy loads as fast as possible. Its higher

torque available at lower velocity, plus dynamic torque from its flywheel mass allow compensating

for mechanical torque peaks. In case the motor becomes completely blocked, the stall flag becomes

set.

19.1 User Benefits

Motor

–

–

–

–

–

never loses steps

Application

Acceleration

Energy efficiency

Cheaper motor

works as fast as possible

automatically as high as possible

highest at speed limit

does the job!

19.2 Designing-In dcStep

In a classical application, the operation area is limited by the maximum torque required at maximum

application velocity. A safety margin of up to 50% torque is required, in order to compensate for

unforeseen load peaks, torque loss due to resonance and aging of mechanical components. dcStep

allows using up to the full available motor torque. Even higher short time dynamic loads can be

overcome using motor and application flywheel mass without the danger of a motor stall. With

dcStep the nominal application load can be extended to a higher torque only limited by the safety

margin near the holding torque area (which is the highest torque the motor can provide).

Additionally, maximum application velocity can be increased up to the actually reachable motor

velocity.

torque

MMAX

microstep

operation

dcStep operation - no step loss can occur

additional flywheel mass torque reserve

m

a

x

.

m

o

t

o

r

t

s

a

f

o

r

q

e

t

y

m

a

r

g

i

n

u

e

MNOM2

dcStep extended

application area

MNOM1

Classic operation area

with safety margin

0

velocity [RPM]

MNOM: Nominal torque required by application

MMAX: Motor pull-out torque at v=0

Safety margin: Classical application operation area is limited by a certain

percentage of motor pull-out torque

Figure 19.1 dcStep extended application operation area

Quick Start

For a quick start, see the Quick Configuration Guide in chapter 24.

For detail configuration procedure see Application Note AN003 - dcStep

www.trinamic.com

TRINAMIC [ TRINAMIC MOTION CONTROL GMBH & CO. KG. ]

TRINAMIC [ TRINAMIC MOTION CONTROL GMBH & CO. KG. ]