UC2625-EP

www.ti.com .................................................................................................................................................................................................. SLUS802–MARCH 2008

+15V

VMOTOR

+5V TO HALL

SENSORS

VREF

+

3kW

100nF

100nF

100mF

+

2N3904

10W

20mF

20mF

10kW

10kW

3kW

ROSC

33kW

2

19

11

QUAD

DIR

2N3906

IRF9350

22

6

3kW

16

17

18

14

13

TO

MOTOR

1k

TO OTHER

CHANNELS

1

28

27

25

UC3625

4kW

REQUIRED

FOR BRAKE

AND FAST

REVERSE

100nF

TO OTHER

CHANNELS

10W

IRF532

2200pF

COSC

12

20

15

10kW

BRAKE

21

26

3

24

23

8

9

10

4

5

7

100nF

5nF

3nF

CT

68kW

RT

REQUIRED

FOR

240W

FROM

HALL

SENSORS

100nF

AVERAGE

CURRENT

SENSING

0.02

W

2nF

5nF

240W

51kW

2nF

2nF

RS

0.02

W

RD

VREF

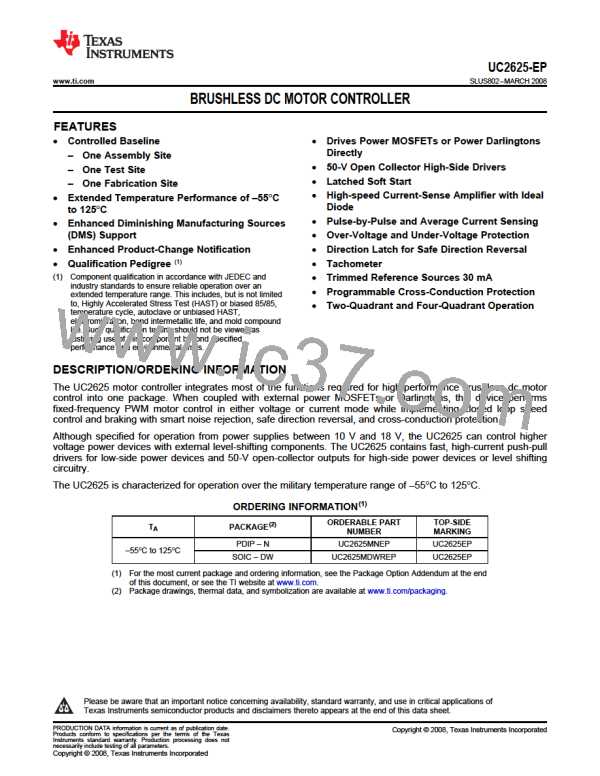

Figure 14. 45-V/8-A Brushless DC Motor Drive Circuit

N-Channel power MOSFETs are used for low-side drivers, while P-Channel power MOSFETs are shown for

high-side drivers. Resistors are used to level shift the UC2625 open-collector outputs, driving emitter followers

into the MOSFET gate. A 12-V zener clamp insures that the MOSFET gate-source voltage never exceeds 12 V.

Series 10-Ω gate resistors tame gate reactance, preventing oscillations and minimizing ringing.

The oscillator timing capacitor should be placed close to pins 15 and 25, to keep ground current out of the

capacitor. Ground current in the timing capacitor causes oscillator distortion and slaving to the commutation

signal.

The potentiometer connected to pin 1 controls PWM duty cycle directly, implementing a crude form of speed

control. This control is often referred to as "voltage mode" because the potentiometer position sets the average

motor voltage. This controls speed because steady-state motor speed is closely related to applied voltage.

Pin 20 (Tach-Out) is connected to pin 7 (SPEED IN) through an RC filter, preventing direction reversal while the

motor is spinning quickly. In two-quadrant operation, this reversal can cause kinetic energy from the motor to be

forced into the power MOSFETs.

A diode in series with the low-side MOSFETs facilitates PWM current control during braking by insuring that

braking current will not flow backwards through low-side MOSFETs. Dual current-sense resistors give continuous

current sense, whether braking or running in four-quadrant operation, an unnecessary luxury for two-quadrant

operation.

The 68-kΩ and 3-nF tachometer components set maximum commutation time at 140 µs. This permits smooth

operation up to 35,000 RPM for four-pole motors, yet gives 140 µs of noise blanking after commutation.

Copyright © 2008, Texas Instruments Incorporated

Submit Documentation Feedback

19

Product Folder Link(s) :UC2625-EP

TI [ TEXAS INSTRUMENTS ]

TI [ TEXAS INSTRUMENTS ]