www.ti.com

ꢀꢁ ꢂ ꢃꢄ ꢅꢆ ꢇ

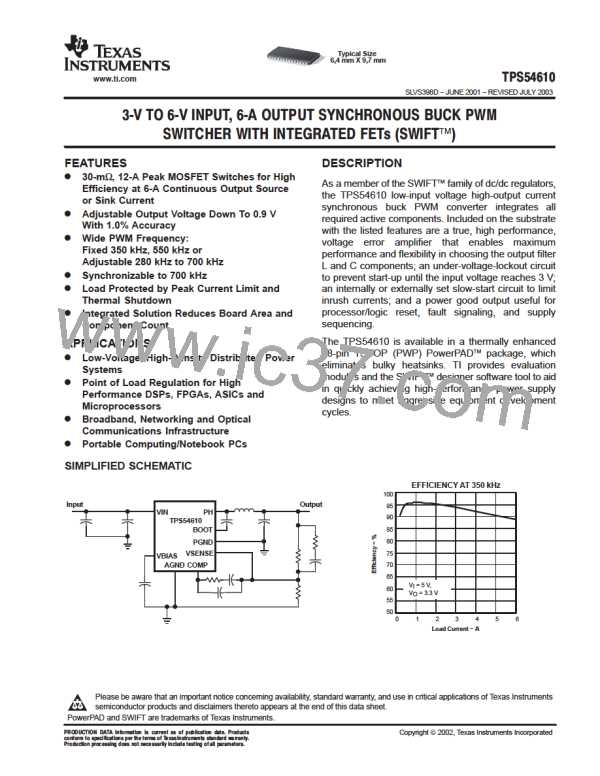

SLVS398D − JUNE 2001 − REVISED JULY 2003

The only components that must tie directly to the power

ground plane are the input capacitor, the output capacitor,

the input voltage decoupling capacitor, and the PGND pins

of the TPS54610. The layout of the TPS54610 evaluation

module is representative of a recommended layout for a

4-layer board. Documentation for the TPS54610

evaluation module can be found on the Texas Instruments

web site under the TPS54610 product folder. See the

TPS54610 EVM user’s guide, TI literature number

SLVU054, and the application note, TI literature number

SLVA104.

OPERATING FREQUENCY

In the application circuit, the 350 kHz operation is selected

by leaving RT and SYNC open. Connecting a 180 kΩ to 68

kΩ resistor between RT (pin 28) and analog ground can be

used to set the switching frequency to 280 kHz to 700 kHz.

To calculate the RT resistor, use the equation below:

500 kHz

Switching Frequency

R +

100 [kW]

(1)

OUTPUT FILTER

LAYOUT CONSIDERATIONS FOR THERMAL

PERFORMANCE

The output filter is composed of a 4.7-µH inductor and two

470-µF capacitors. The inductor is a low dc resistance (12

mΩ) type, Coiltronics UP3B−4R7. The capacitors used

are 4 V POSCAP types with a maximum ESR of 0.040 Ω.

The feedback loop is compensated so that the unity gain

frequency is approximately 25 kHz.

For operation at full rated load current, the analog ground

plane must provide an adequate heat dissipating area. A

3-inch by 3-inch plane of 1 ounce copper is recommended,

though not mandatory, depending on ambient temperature

and airflow. Most applications have larger areas of internal

ground plane available, and the PowerPAD must be

connected to the largest area available. Additional areas

on the top or bottom layers also help dissipate heat, and

any area available must be used when 6 A or greater

operation is desired. Connection from the exposed area of

the PowerPAD to the analog ground plane layer must be

made using 0.013 inch diameter vias to avoid solder

wicking through the vias. Eight vias must be in the

PowerPAD area with four additional vias located under the

device package. The size of the vias under the package,

but not in the exposed thermal pad area, can be increased

to 0.018. Additional vias beyond the twelve recommended

that enhance thermal performance must be included in

areas not under the device package.

GROUNDING AND POWERPAD LAYOUT

The TPS54610 has two internal grounds (analog and

power). Inside the TPS54610, the analog ground ties to all

of the noise sensitive signals, while the power ground ties

to the noisier power signals. The PowerPAD must be tied

directly to AGND. Noise injected between the two grounds

can degrade the performance of the TPS54610,

particularly at higher output currents. However, ground

noise on an analog ground plane can also cause problems

with some of the control and bias signals. Therefore,

separate analog and power ground planes are

recommended. These two planes must tie together

directly at the IC to reduce noise between the two grounds.

Minimum Recommended Thermal Vias: 8 x 0.013 Diameter Inside

Powerpad Area 4 x 0.018 Diameter Under Device as Shown.

Additional 0.018 Diameter Vias May Be Used if Top Side Analog Ground

Area Is Extended.

Ø0.0130

8 PL

4 PL Ø0.0180

Connect Pin 1 to Analog Ground Plane

in This Area for Optimum Performance

0.0150

0.06

0.0339

0.0650

0.0500

0.3820 0.3478

0.2090

0.0256

0.0500

0.0500

0.0650

0.0339

Minimum Recommended Exposed

Copper Area for Powerpad. 5mm

Stencils May Require 10 Percent

0.1700

Larger Area

0.1340

0.0630

Minimum Recommended Top

Side Analog Ground Area

0.0400

Figure 11. Recommended Land Pattern for 28-Pin PWP PowerPAD

9

TI [ TEXAS INSTRUMENTS ]

TI [ TEXAS INSTRUMENTS ]