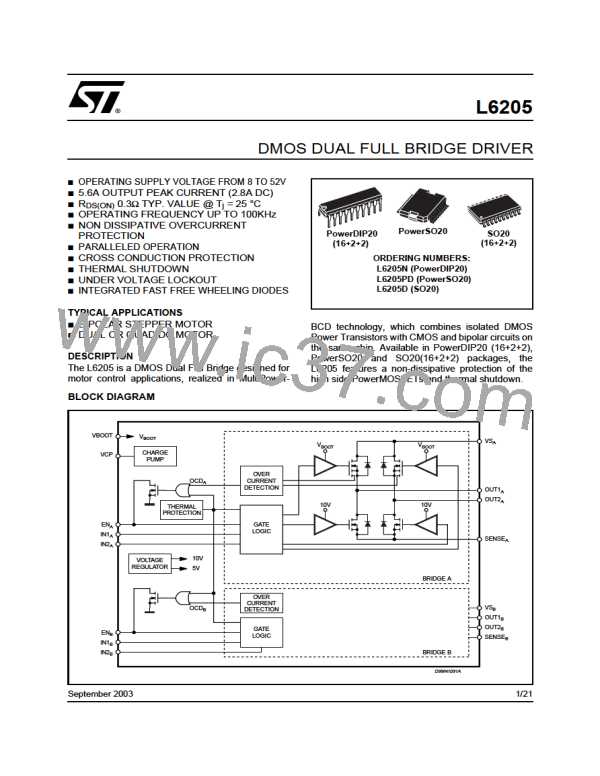

L6205

Figure 17. Mounting the PowerSO package.

Slug soldered

to PCB with

dissipating area

Slug soldered

Slug soldered to PCB with

dissipating area plus ground layer

contacted through via holes

to PCB with

dissipating area

plus ground layer

Figure 18. PowerSO20 Junction-Ambient thermal resistance versus on-board copper area.

ºC / W

43

38

33

W ithout Ground Layer

28

W ith Ground Layer

W ith Ground Layer+16 via

H oles

23

On-Board Copper Area

18

13

1

2

3

4

5

6

7

8

9

10 11 12 13

sq. cm

Figure 19. PowerDIP20 Junction-Ambient thermal resistance versus on-board copper area.

ºC / W

On-Board Copper Area

42

41

Copper Area is on Bottom Side

40

Copper Area is on Top Side

39

38

37

36

35

34

33

1

2

3

4

5

6

7

8

9

10 11 12

sq. cm

Figure 20. SO20 Junction-Ambient thermal resistance versus on-board copper area.

ºC / W

On-Board Copper Area

68

66

64

62

60

C o pp er Are a is on Top Sid e

58

56

54

52

50

48

1

2

3

4

5

6

7

8

9

10 11 12

sq. cm

16/21

STMICROELECTRONICS [ ST ]

STMICROELECTRONICS [ ST ]