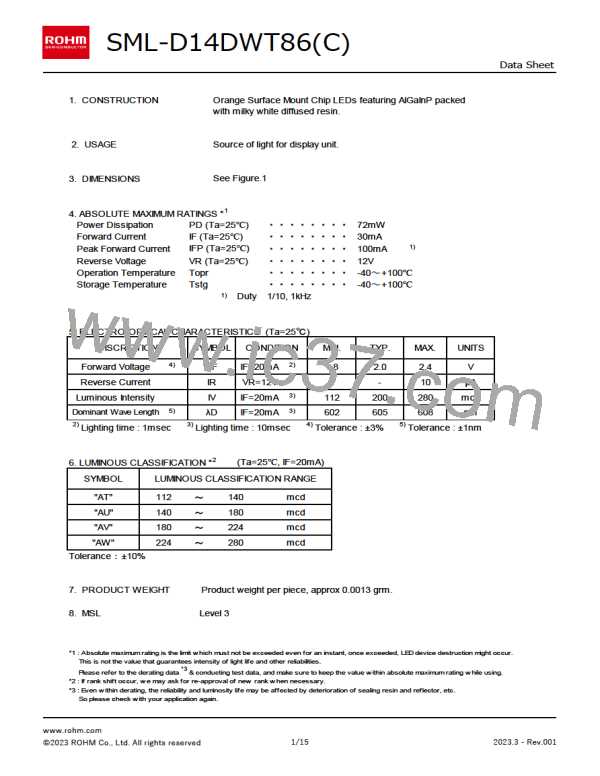

[SML-D14DWT86(C)]

[Data Sheet]

ꢀꢀꢀꢀ

4.Mounting

4-1. Soldering

・No resin hardening agent such as filler is used in the sealing resin of the product. Therefore, resin expansion

and moisture absorption at humidity will cause heat stress during soldering process and finally has bad influence

on the product’s reliability.

・The product is not guaranteed for flow soldering.

・Thermal stress during the flow soldering of surrounding parts will influence the reliability of LED and please

evaluate the soldering conditions before using it. Also please make sure the expiration date after opening the

moistureproof package.

・Please set appropriate reflow temperature based on our product usage conditions and specification.

・The max for reflowing is 2 times, please finish the second reflow soldering and flow soldering with other parts

within the usage limitation after open the moistureproof package.

・Compare with N2 reflow, during air reflow, because of the heat and surrounding conditions, it may cause the

discoloration of the resin.

・For our product that has no solder resist, because of its solder amount and soldering conditions, one of its

specific characteristics is that solder will penetrate into LED. Thus, there's high possibility that will influence its

reliability. Therefore, please be informed, concerning it before using it.

4-2. Automatic Mounting

4-2-1.Suction nozzle

Excessive load may cause damage inside the LED product, so select an optimal suction nozzle according to the

material and shape of the LED product.

4-2-2.Mini Package (Smaller than 1608 size)

Vibration may result in low mounting rate since it will cause the static electricity of product and adhere to top cover

tape. We recommend to

・set magnet on parts feeder cassette of the mounter to control the product stabilization

・set ionizer to prevent electrostatic charge

4-3. Mounting Location

The stress like bending stress of circuit board dividing after mounting, may cause LED package crack or damage

of LED internal junction, therefore, please concern the mounting direction and position to avoid bending or

screwing with great stress of the circuit board.

Stress strength according to

the mounting position:

A>B>C>D

4-4. Mechanical Stress after Mounting

The mechanical stress may damage the LED after circuit mounting, so please pay attention to the touch on product.

4-5. Soldering Pattern for Recommendation

We recommend the soldering pattern that shows on the right.

It will be different according to mounting situation of circuit board,

therefore, please concern before designing.

※The product has adopted the electrode structure that it should solder

with back electrode of the product.

Thus, please be informed that the shape of electrode pin of

solder fillet formation is not guaranteed.

The through hole on electrode surface is for conduction of front

and rear electrodes but not for formation of solder fillet.

(Unit:mm)

www.rohm.com

©2023 ROHM Co., Ltd. All rights reserved

9/15

2023.3 - Rev.001

ロ

ROHM [ ROHM ]

ROHM [ ROHM ]