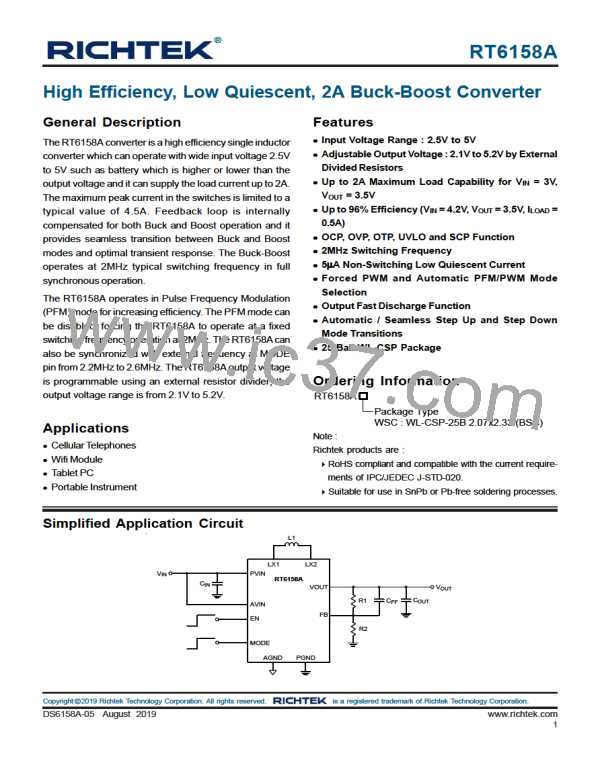

RT6158A

Protection

Type

Threshold Refer

to Electrical Spec.

Protection Method

Shut Down Delay Time

Reset Method

IL < 4.5A

CL will trigger right

away.

OCP

IL > 4.5A

Turn on B, D MOS

UVLO

OTP

VIN < 2.05V

Shutdown

100s

VIN > 2.15V

TEMP > 160°C

Shutdown

No delay

No delay

No delay

OTP Hysteresis = 20°C

VOUT < 5.3V

Output OVP VOUT > 5.6V

SCP VOUT < 1.2V

Stop switching

fSW become 1/4

After FAULT 40ms

If the RT6158A operates in Buck mode, the worst-case

voltage ripple occurs at the highest input voltage. When

the Buck-boost operates in Boost mode, the worst-case

voltage ripple occurs at the lowest input voltage. A

capacitor with a value in the range of the calculated

minimum should be used. This is required to maintain

control loop stability. There are no additional requirements

regarding minimum ESR. Low ESR capacitors should be

used to minimize output voltage ripple. Larger capacitors

will cause lower output voltage ripple as well as lower

output voltage drop during load transients.

Over-Temperature Protection

The device has a built-in temperature sensor which

monitors the internal junction temperature. If the

temperature exceeds the OTP threshold, the device stops

operating and enters shutdown mode. As soon as the IC

temperature decreases below the threshold with a

hysteresis, it starts operating again.

Over-Voltage Protection

When the VOUT pin is floating, the device will trigger the

over-voltage protection to avoid the output voltage

exceeding critical values for device. In case it reaches the

OVP threshold, the device will regulate the output voltage

to this value.

Thermal Considerations

The junction temperature should never exceed the

absolute maximum junction temperature TJ(MAX), listed

under Absolute Maximum Ratings, to avoid permanent

damage to the device. The maximum allowable power

dissipation depends on the thermal resistance of the IC

package, the PCB layout, the rate of surrounding airflow,

and the difference between the junction and ambient

temperatures. The maximum power dissipation can be

calculated using the following formula :

Inductor Selection

The recommended power inductor is 1μH with over 4.5A

saturation current rating. In applications, it needs to select

an inductor with the low DCR for good performance and

efficiency.

Input and Output Capacitor Selection

The input and output capacitors should be ceramic X5R

type with low ESL and ESR. The recommended input

capacitor value is 2 x 10μF. The recommended output

capacitor value is 4 x 10μF.

PD(MAX) = (TJ(MAX) − TA) / θJA

where TJ(MAX) is the maximum junction temperature, TA is

the ambient temperature, and θJA is the junction-to-ambient

thermal resistance.

The output capacitor selection determines the output

voltage ripple and transient response. It is recommended

to use ceramic capacitors placed as close as possible to

the VOUT and GND pins of the IC. If, for any reason, the

application requires the use of large capacitors which

cannot be placed close to the IC, using a small ceramic

capacitor in parallel to the large one is recommended.

This small capacitor should be placed as close as possible

to the VOUT and GND pins of the IC.

For continuous operation, the maximum operating junction

temperature indicated under Recommended Operating

Conditions is 125°C. The junction-to-ambient thermal

resistance, θJA, is highly package dependent. For a WL-

CSP-25B 2.07x2.33 (BSC) package, the thermal

resistance, θJA, is 35.7°C/W on a standard JEDEC 51-7

high effective-thermal-conductivity four-layer test board.

Copyright 2019 Richtek Technology Corporation. All rights reserved.

©

is a registered trademark of Richtek Technology Corporation.

www.richtek.com

10

DS6158A-05 August 2019

RICHTEK [ RICHTEK TECHNOLOGY CORPORATION ]

RICHTEK [ RICHTEK TECHNOLOGY CORPORATION ]