Precautions

Wiring

Relays Mounted

Be sure to turn OFF the power when wiring the Unit and do not touch

the charged terminals of the Unit. Otherwise, an electric shock may

result.

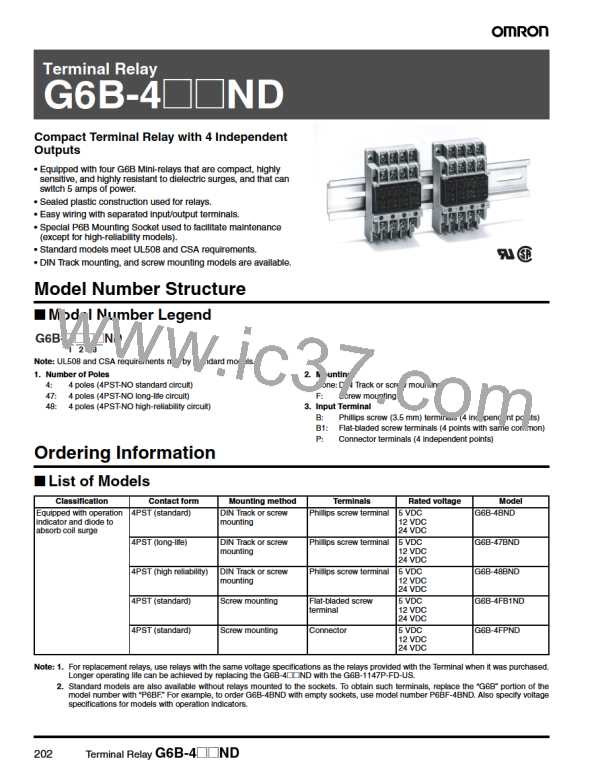

G6B-4@@ND standard:

G6B-1114P-FD-US

G6B-1174P-FD

G6B-4@@ND long life:

G6B-4@@ND high reliability: G6B-1184P-US

Replacement is not possible for G6B-48BND.

Do not apply overvoltage to the input terminals. Otherwise, the Unit

may malfunction or burn.

Wiring

Relay Models

Be sure to connect the input terminals with the correct polarity.

Do not connect the Unit to loads exceeding the rated switching power

(switching voltage or current). Otherwise, faulty insulation, contact

weld, or faulty contact of Relays, or damage to Relays may result, or

the Relays may malfunction or burn.

The life of Relays varies with the switching condition. Test the Relays

under the actual operating conditions before using the Relays within

the permissible switching frequency. The use of deteriorated Relays

may result in the faulty insulation of the Relays or cause the Relays

to burn.

Coil Voltage

Be sure not to impose voltage exceeding the permissible voltage on

the coil continuously.

Do not use the relays when other inductive loads are connected in

parallel with the coil input or when there are surges during power

supply because the built-in diodes used to absorb surge may be

destroyed.

Do not use the Unit in locations with inflammable gas. Otherwise, a

fire or explosion due to the heat of the Relays or sparks from the

Relays may result when they are switched.

Do Not Use the Following Circuit

■ Correct Use

Coil surge current

absorption diode

Inductive load

G6B Coil

Mounting

Heat generated by the relays must be considered when gang-mount-

ing. Space must be provided between the relays or other methods

must be taken to maintain the relays’ ambient temperature at 55 °C

or lower.

Handling

Do not drop, shock, or vibrate the Unit excessively. Otherwise, dam-

age to the Unit may result or the Unit may malfunction.

Replacement of Relays

Make sure that all the Relays are properly mounted before use.

G6B-4@@ND

Use the P6B-Y1 Removal Tool as shown in the following diagram.

Screw Tightening Torque

Tighten each terminal screw to a torque of 0.78 to 1.18N·m.

Tighten each mounting screw to a torque of 0.59 to 0.98 N·m.

Installation Environment

Do not install the Unit in the following locations. Otherwise, damage

to the Unit may result or the Unit may malfunction.

Locations with direct sunlight.

Locations with an ambient temperature range not within 0°C to 55°C.

Locations with rapid temperature changes resulting in condensation

or locations with relative humidity ranges not within 10% to 90%.

Locations with corrosive or inflammable gas.

Locations with excessive dust, salinity, or metal powder.

Locations with vibration or shock affecting the Unit.

Locations with water, oil, or chemical sprayed on the Unit.

Be sure to turn OFF the power to the Unit before replacing a Relay.

Relays must be inserted straight onto the socket connector pins to

ensure proper connection.

G6B-48BND models (high reliability) are connected directly to

boards to increase reliability and the relays are thus not replaceable.

If relay replacement is necessary, use the P6BF-4BND Terminal

Sockets together with the G6B-1184P Mini Relays. P6BF-4BND Ter-

minal Sockets are equipped with relay replacement sockets.

Disassembly, Repair, and Modification

Do not disassemble, repair, or modify the Unit. Otherwise, an electric

shock may result or the Unit may malfunction.

Do not mount Relays that are different to one another in voltage.

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

In the interest of product improvement, specifications are subject to change without notice.

Cat. No. J098-E1-02A

Terminal Relay G6B-4@@ND

207

OMRON [ OMRON ELECTRONICS LLC ]

OMRON [ OMRON ELECTRONICS LLC ]