MPQ4560 – 2A, 2MHz, 55V, STEP-DOWN CONVERTER

3) Route SW away from sensitive analog

areas such as FB.

PCB LAYOUT GUIDE

PCB layout is very important for stable

operation. Try to duplicate the EVB layout for

optimum performance.

4) Connect IN, SW, and especially GND to

large copper surfaces to cool the chip to

improve thermal performance and long-

term reliability.

For changes, please follow these guidelines

and use Figure 5 as reference.

5) Place the compensation components close

to the MPQ4560. Avoid placing the

compensation components close to or

under high dv/dt SW node, or inside the

high di/dt power loop. If necessary, add a

ground plane to isolate the loops.

1) Place the input decoupling capacitor and

the catch diode as close to the MPQ4560

(VIN pin, SW pin and PGND) as possible,

with traces that are very short and fairly

wide. This can help to greatly reduce the

voltage spike on SW node, and the EMI

noise.

6) Switching loss increases at higher

frequencies.

To

improve

thermal

2) Ensure all feedback connections are short

and direct. Place the feedback resistors

and compensation components as close to

the chip as possible. Try to run the

feedback trace as far from the inductor and

noisy power traces as possible. Run the

feedback trace on the side of the PCB

opposite of the inductor with a ground

plane separating the two.

conduction, add a grid of thermal vias

under the exposed pad. Use small vias

(15mil barrel diameter) so that the hole fills

during the plating process: larger vias can

cause solder-wicking during the reflow

process. The pitch (distance between the

centers) between these thermal vias is

typically 40mil.

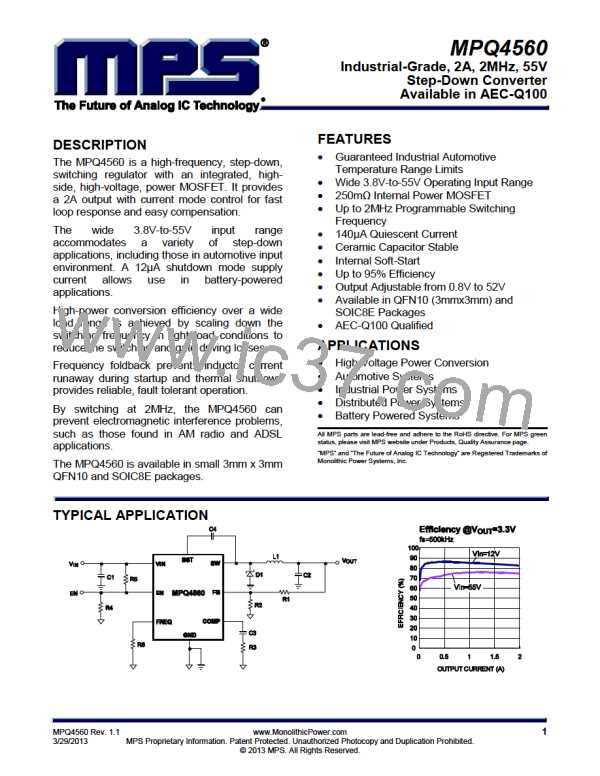

MPQ4560 Typical Application Circuit

MPQ4560 Rev. 1.1

3/29/2013

www.MonolithicPower.com

MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2013 MPS. All Rights Reserved.

18

MPS [ MONOLITHIC POWER SYSTEMS ]

MPS [ MONOLITHIC POWER SYSTEMS ]