These focal smears overlap, creating an

points source; and the aperture size should be

equal to that of the epoxy dome at its base as

shown in Figure 5.5.

elongated focal smear as shown in Figure 5.4.

To create the best approximation using a point

source model, the center point of the focal

smears should be chosen as the location of the

The optimal position of the point source for each

SuperFlux LED is shown in Table 5.1.

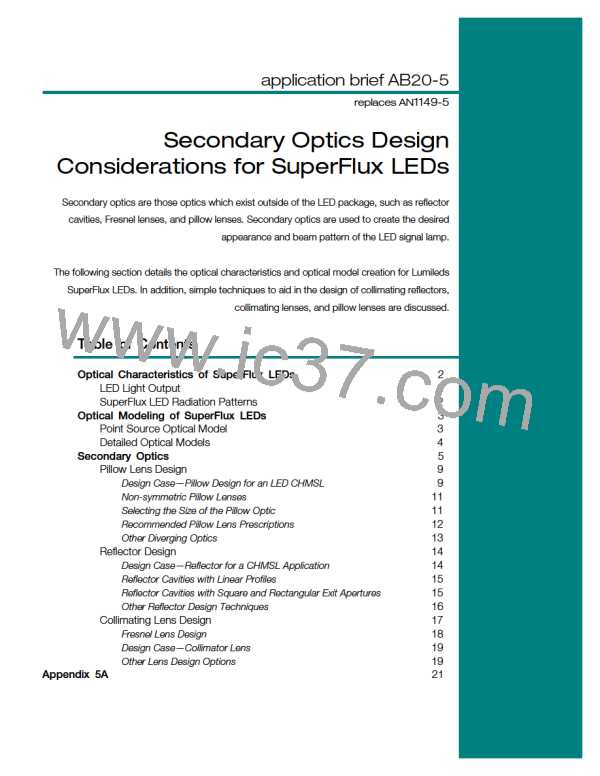

Figure 5.3 Internal structure of a SuperFlux

LED.

Figure 5.4 Focal smear produced by reflected

and reflected-refracted light.

Detailed Optical Models

Detailed optical models of LEDs include all

the internal optical structures within the LED

including the chip, the reflector, and the dome.

In order to accurately construct such a model,

detailed information about the chip, the reflector

surface, and the epoxy encapsulant must be

known. The process usually involves a tedious

trial and error technique of changing parameters

in the model until empirical measurements are

matched.

Table 5.1

Position of Point Source for SuperFlux LEDs

SuperFlux LED

Part Number

Position of Point Source

“Z” (mm)

HPWA-MxOO

HPWA-Dx00

HPWT-Mx00

HPWT-DxOO

1.03

1.13

0.99

1.17

Due to the complexity of this process, Lumileds

Lighting provides customers with rayset files for

SuperFlux LEDs. The raysets contain spacial

and angular information on a set of rays exiting

the device at the dome surface. These raysets

can be used by many optical-modeling software

packages. Contact your local Lumileds

Applications Engineer for more information and

copies of the raysets.

4

LUMILEDS [ LUMILEDS LIGHTING COMPANY ]

LUMILEDS [ LUMILEDS LIGHTING COMPANY ]