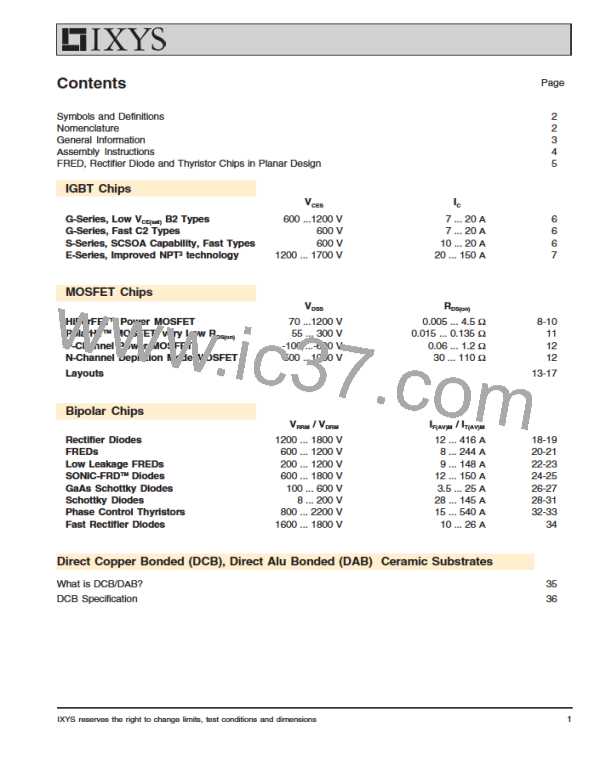

FRED, Rectifier Diode and Thyristor Chips in Planar Design

Fast Recovery Epitaxial Diodes (FRED)

Power switches (IGBT, MOSFET, BJT, GTO) for applications in electronics are only as good as their associated free-wheeling

diodes. At increasing switching frequencies, the proper functioning and efficiency of the power switch, aside from conduction losses,

is determined by the turn-off behavior of the diode (characterized by Qrr, IRM and trr - Fig. 1.

The reverse current character-istic following the peak reverse current IRM is

another very im-portant property. The slope of the decaying reverse current

dirr/dt results from design para- meters (technology and dif-fusion of the

FRED chip Fig. 2. In a circuit this current slope, in conjunction with parasitic

induc-tances (e.g. connecting leads, causes over-voltage spikes and high

frequency interference vol-tages.The higher the dirr/dt ("hard recovery" or

"snap-off" behavior) the higher is the resulting additional stress for both the

diode and the paralleled switch. A slow decay of the reverse current ("soft

recovery" behavior), is the most desirable characteristic, and this is designed

into all FRED. The wide range of available blocking voltages makes it

possible to apply these FRED as output rectifiers in switch-mode power

supplies (SMPS) as well as protective and free-wheeling diodes for power

switches in inverters and welding power supplies.

Fig. 1: Current and voltage during turn-on and

turn-off switching of fast diodes

Glasspassivation

Rectifier Diode and Thyristor Chips

Guard ring

The figures 3 a-c show cross sectional views of the diode and thyristor

Anode

Anode

chips in the passivation area. All thyristor and diode chips (DWN, DWFN,

CWP) are fabricated using separation diffusion processes so that all

Epitaxie Schicht n-

Epitaxy layer n-

junctions terminate on the topside of the chip. Now the entire bottom

surfaces of all chips are available for soldering onto a DCB or other ceramic

substrate without a molybdenum strain buffer. The elimination of the strain

buffer and its solder joint reduces thermal resistance and increases

blocking voltage stability. The junction termination areas are passivated

with glass, whose thermal expansion coefficient matches that of silicon. All

silicon chips increasingly use planar technology with guard rings and

channel stoppers to reduce electric fields on the chip surface.

Substrat n+

Substrate n+

Kathode

Cathode

Metalization

Fig. 2: Cross section of glassivated planar epitaxial

diode chip with seperation diffusion (type DWEP)

The contact areas of the chips have vapor deposited metal layers which

contribute substantially to their high power cycle capability. All chips are

processed on silicon wafers of 5" diameter and diced after a wafer sample

test which auto-matically marks chips not meeting the electrical specification.

The chip geometry is square or rectangular.

Guard ring

Glasspassivation

Fig. 3a-c

Cross sections of Chips in the passivation area

a) Diode chip, type DWN, DWFN

b) Diode chip, type DWP, DWFP

c) Thyristor chip, type CWP

p

n

Fig. 3b)

n+

Glasspassivation

Metalization

Glasspassivation

Emitter

Guard ring

Channel-

Fig. 3a)

stopper

Fig. 3c)

Metalization

Metalization

IXYS reserves the right to change limits, test conditions and dimensions

5

IXYS [ IXYS CORPORATION ]

IXYS [ IXYS CORPORATION ]