Applications Information: continued

Output Inductor

COFF timing capacitor:

The inductor should be selected based on its inductance,

Period × (1 - duty cycle)

current capability, and DC resistance. Increasing the induc-

tor value will decrease output voltage ripple, but degrade

transient response.

COFF

=

,

4848.5

where:

1

Period =

Thermal Management

switching frequency

Thermal Considerations for Power MOSFETs and Diodes

In order to maintain good reliability, the junction tempera-

ture of the semiconductor components should be kept to a

maximum of 150°C or lower. The thermal impedance (junc-

tion to ambient) required to meet this requirement can be

calculated as follows:

Schottky Diode for Synchronous MOSFET

A Schottky diode may be placed in parallel with the syn-

chronous MOSFET to conduct the inductor current upon

turn off of the switching MOSFET to improve efficiency.

The CS5155H reference circuit does not use this device due

to it’s excellent design. Instead, the body diode of the syn-

chronous MOSFET is utilized to reduce cost and conducts

the inductor current. For a design operating at 200kHz or so,

the low non-overlap time combined with Schottky forward

recovery time may make the benefits of this device not

worth the additional expense (see Figure 6, channel 2). The

power dissipation in the synchronous MOSFET due to body

diode conduction can be estimated by the following equation:

TJUNCTION(MAX) - TAMBIENT

Thermal Impedance =

Power

A heatsink may be added to TO-220 components to reduce

their thermal impedance. A number of PC board layout

techniques such as thermal vias and additional copper foil

area can be used to improve the power handling capability

of surface mount components.

Power = Vbd × ILOAD × conduction time × switching frequency

EMI Management

As a consequence of large currents being turned on and off

at high frequency, switching regulators generate noise as a

consequence of their normal operation. When designing for

compliance with EMI/EMC regulations, additional com-

ponents may be added to reduce noise emissions. These

components are not required for regulator operation and

experimental results may allow them to be eliminated. The

input filter inductor may not be required because bulk filter

and bypass capacitors, as well as other loads located on the

board will tend to reduce regulator di/dt effects on the cir-

cuit board and input power supply. Placement of the

power component to minimize routing distance will also

help to reduce emissions.

Where Vbd = the forward drop of the MOSFET body diode.

For the CS5155H demonstration board as shown in Figure 6;

Power = 1.6V × 13A × 100ns × 233kHz = 0.48W

This is only 1.3% of the 36.4W being delivered to the load.

“Droop” Resistor for Adaptive Voltage Positioning

Adaptive voltage positioning is used to reduce output volt-

age excursions during abrupt changes in load current.

Regulator output voltage is offset +40mV when the regula-

tor is unloaded, and -40mV at full load. This results in

increased margin before encountering minimum and maxi-

mum transient voltage limits, allowing use of less capaci-

tance on the regulator output (see Figure 7).

To implement adaptive voltage positioning, a “droop”

resistor must be connected between the output inductor

and output capacitors and load. This is normally imple-

mented by a PC board trace of the following value:

2µH

2µH

+

80mV

IMAX

1200µF x 3/16V

33Ω

RDROOP

=

1000pF

Adaptive voltage positioning can be disabled for improved

DC regulation by connecting the VFB pin directly to the load

using a separate, non-load current carrying circuit trace.

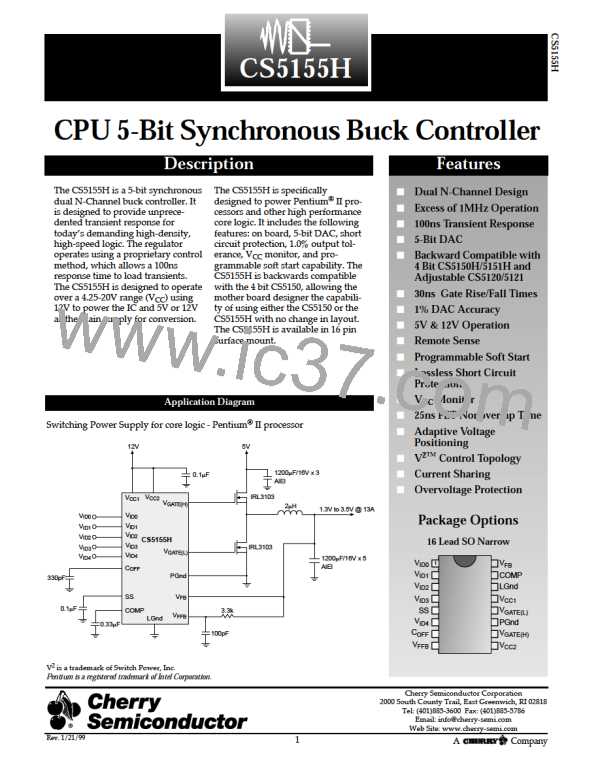

Figure 18: Filter components

Figure 19: Input Filter

Input and Output Capacitors

Layout Guidelines

These components must be selected and placed carefully to

yield optimal results. Capacitors should be chosen to pro-

vide acceptable ripple on the input supply lines and regula-

tor output voltage. Key specifications for input capacitors

are their ripple rating, while ESR is important for output

capacitors. For best transient response, a combination of

low value/high frequency and bulk capacitors placed close

to the load will be required.

1. Place 12V filter capacitor next to the IC and connect

capacitor ground to pin 11 (PGnd).

2. Connect pin 11 (PGnd) with a separate trace to the

ground terminals of the 5V input capacitors.

3. Place fast feedback filter capacitor next to pin 8 (VFFB

and connect it’s ground terminal with a separate, wide

trace directly to pin 14 (LGnd).

)

12

CHERRY [ CHERRY SEMICONDUCTOR CORPORATION ]

CHERRY [ CHERRY SEMICONDUCTOR CORPORATION ]