WORLD-BEAM QS18U Ultrasonic Sensors

Temperature Effects

The speed of sound is dependent upon the composition, pressure and temperature of the gas in which it is traveling. For

most ultrasonic applications, the composition and pressure of the gas are relatively fixed, while the temperature may

fluctuate.

In air, the speed of sound varies with temperature according to the following approximation:

In metric

units:

In English units:

C

=

√

=

C

ft/s

√

49 460 + T

F

20 273 + T

m/s

C

Cm/s = speed of sound in meters per second

TC = temperature in °C

Cft/s = speed of sound in feet per second

TF = temperature in °F

Temperature Compensation

Changes in air temperature affect the speed of sound, which in turn affects the distance reading measured by the sensor.

An increase in air temperature shifts both sensing window limits closer to the sensor. Conversely, a decrease in air

temperature shifts both limits farther away from the sensor. This shift is approximately 3.5% of the limit distance for a 20°

C change in temperature.

The QS18U series ultrasonic sensors are temperature compensated This reduces the error due to temperature by about

90%. The sensor will maintain its window limits to within 1.8% over the -20° to +60° C (−4° to +140° F) range.

NOTE:

•

•

•

Exposure to direct sunlight can affect the sensor’s ability to accurately compensate for changes

in temperature.

If the sensor is measuring across a temperature gradient, the compensation will be less

effective.

The temperature warmup drift upon power-up is less than 7% of the sensing distance. After 5

minutes, the apparent switchpoint will be within 0.6% of the actual position. After 25 minutes,

the sensing position will be stable.

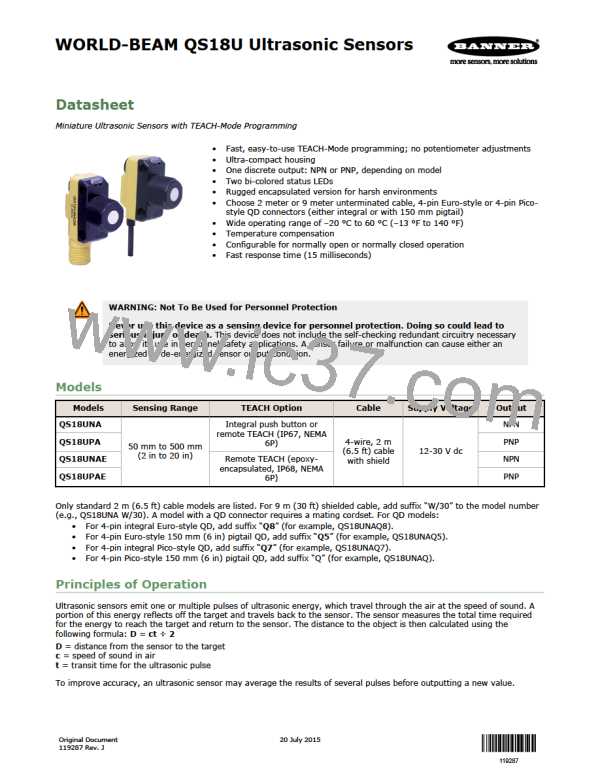

Sensor Programming

Two TEACH methods may be used to program the sensor:

Green/Red

Power/Signal

Strength LED

Yellow/Red

TEACH/Output

Indicator LED

•

•

Teach individual minimum and maximum limits, or

Use Auto-Window feature to center a sensing window around the taught

position

Push Button

(IP67 models only)

The sensor may be programmed either via its push button, or via a remote

switch. Remote programming also may be used to disable the push button,

preventing unauthorized personnel from adjusting the programming settings. To

access this feature, connect the white wire of the sensor to 0V dc, with a remote

programming switch between the sensor and the voltage.

Figure 1. Sensor Features

Programming is accomplished by following the sequence of input pulses (see programming procedures). The duration of

each pulse (corresponding to a push button “click”), and the period between multiple pulses, are defined as “T: 0.04

seconds < T < 0.8 seconds."

2

www.bannerengineering.com - Tel: +1-763-544-3164

P/N 119287 Rev. J

BANNER [ Banner Engineering ]

BANNER [ Banner Engineering ]