Qualification Plan:

HFBR‐1521Z

HFBR‐1527Z

HFBR‐2521Z

HFBR‐2526Z

Test

Reference

Condition

Test Points

Assessment

Assessment

Assessment

Assessment

Result

Result

Result

Result

24hrs bake @125°C,

192 +5/‐0 hrs soak at 30°C

/60%RH,

1x wavesolder 260°C/+

5°C, 10s

Moisture Level

MSL‐3 Definition (MLD)

MSL – 3

0/11

Pass

0/11

Pass

0/11

Pass

SAM: check

Delamination @ 0hrs and

after solder

JEDEC 020D.1

24hrs bake @125°C,

96 +5/‐0 hrs soak at 30°C

/60%RH,

1x wavesolder 260°C/+

5°C, 10s

Moisture Level

MSL‐4 Definition (MLD)

MSL – 4

0/11

0/33

Pass

Pass

Temperature

Cycling

(TMCL)

MIL‐STD‐883

Method 1010

200cyc, 500cyc, and

1000cyc @ 25°C

TMCL

uB85/85

B85/85

HTOL

Ta = ‐40°C to +100°C

0/33

0/22

Pass

Pass

0/33

0/22

Pass

Pass

0/33

Pass

TX: Unbiased

Damp Heat

(UB85/85)

MIL‐STD‐202

Method 103

Ta= 85°C, RH=85%

Vcc=5,25V,

168hrs, 500hrs and

1000hrs @ 25°C

RX: Biased Damp

Heat (B85/85)

0/22

0/22

0/11

0/11

Pass

Pass

Pass

Pass

0/22

0/22

0/11

0/11

Pass

Pass

Pass

Pass

High Temperature

Operating Life

(HTOL)

Section 5.18 (GR‐

468‐CORE)

168hrs, 500hrs and

1000hrs @ 25°C

Ta = 85°C, Vcc=5,25V

0/22

0/11

0/11

Pass

Pass

Pass

0/22

0/11

0/11

Pass

Pass

Pass

1500g (peak), 0.5ms,

5 pulses/surface, 6

surfaces

Mechanical Shock

(MS)1

MIL‐STD‐883

Method 2002B

MS/MV

Post MS/MV

20 – 2000HZ, 20 G

4min/cycle, 4cycle/axis,

3 axis

Mechanical

Vibration (MV)1

MIL‐STD‐883

Method 2007A

___________________________________________________________________________________________

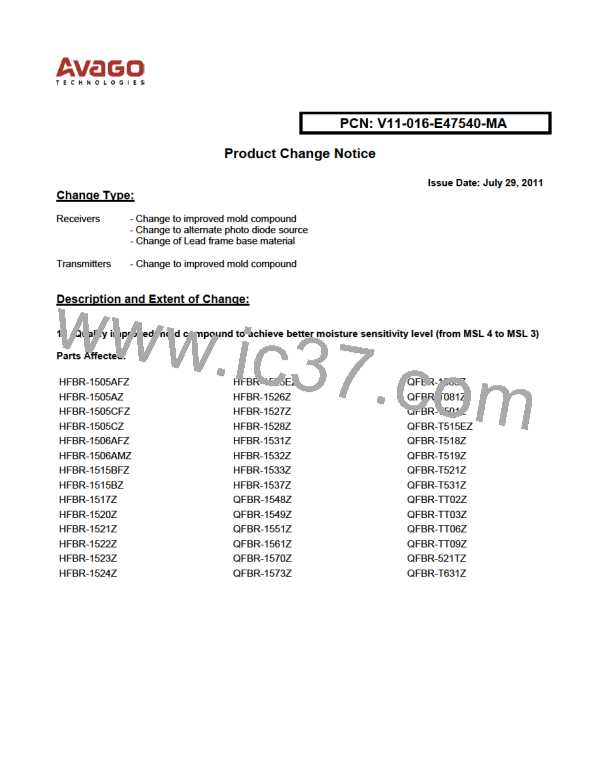

These changes have been reviewed and approved by Avago Technologies engineers and managers per Avago

Technologies procedure: Change Control and Customer Notification, A-5962-6052-80.

Please contact your Avago Technologies field sales engineer or Contact Center (http://www.avagotech.com/contact/ ) for

any questions or support requirements. Please return any response as soon as possible, but not to exceed 30 days.

AVAGO [ AVAGO TECHNOLOGIES LIMITED ]

AVAGO [ AVAGO TECHNOLOGIES LIMITED ]